- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

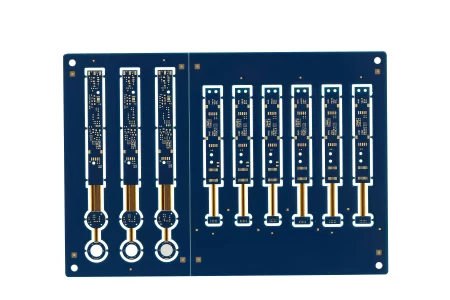

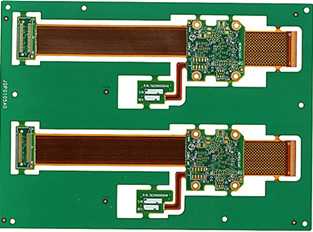

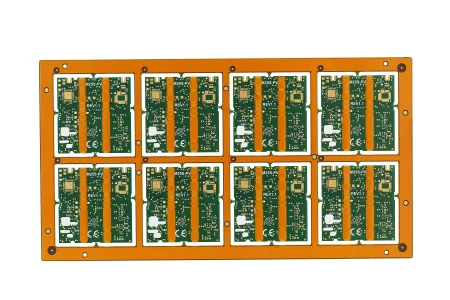

12-layer rigid-flex PCB is a combination of flexible PCB and rigid PCB to form a circuit board with higher performance and more features. The 12-layer rigid-flex PCB, which does not necessarily include a 6-layer rigid PCB and a 6-layer flexible PCB, is composed according to the design requirements. It is possible to have an 8-layer rigid PCB and a 4-layer flexible PCB. Among them, rigid PCBs are mainly used to support and hold electronic components, while flexible PCBs are used to connect various parts. This combination allows the board to be more flexible and reliable and can cope with complex layout and design requirements.

In the manufacturing process, rigid PCBs and flexible PCBs are made first, and then they are combined through a special process. This technology is often used in high-end applications such as medical devices, aerospace and military equipment, and more.

Higher reliability: The combination of hardware and software can provide better electrical and mechanical properties, making the circuit board more stable and reliable.

Higher level of integration: More components and connections can be implemented in a smaller area due to more layers.

More flexible design: Flexible PCBs can be bent and stretched when needed, which can cope with complex layout and design requirements.

Space-saving: Since the combination of hardware and software can implement multiple functions on a single board, it saves space and makes the device smaller and lighter.

Higher performance: Higher performance requirements can be achieved because the combination of rigid-soft can provide better electrical and mechanical properties.

Lower EMI (Electromagnetic Interference): 12-layer rigid-flex PCB reduces interference and signal noise on the board, thereby reducing EMI.

Better heat dissipation: Since the combination of software and hardware can increase the heat dissipation layer, the heat can be better dispersed, thus improving the heat dissipation performance.

Higher anti-interference ability: Since the combination of software and hardware can provide better shielding effect, the anti-interference ability of the circuit board can be improved.

Longer lifespan: The life of the circuit board can be extended due to the combination of rigid-flex can provide better mechanical and electrical properties.

Faster transmission speed: Faster data transmission speeds can be achieved due to the combination of hardware and software that can provide better signal transmission performance.

Material selection and design: Select suitable materials, such as high-frequency materials, high-temperature materials, corrosion-resistant materials, etc., and carry out reasonable design to ensure the performance and reliability of the board.

Quality control of finished products: During the production process, strict quality control of each layer of board is required to ensure the connectivity and electrical performance of each layer.

High-density wiring: As the number of board layers increases, the wiring density will also increase, and higher-level CAD software is required for wiring design to ensure signal stability and reliability.

Interlayer insulation: In multilayer boards, each layer needs to be insulated to avoid electrical interference and signal crosstalk.

Assembly and testing: The assembly and testing process of multilayer PCBs is relatively complex and requires the use of high-level equipment and technology for assembly and testing to ensure product quality.

Thermal management: The circuit components in the multilayer PCB are becoming more and more concentrated, and the heat generated is also increasing, and effective thermal management techniques such as heat sinks, fans, etc., are required to ensure the normal operation of the circuit components.

High-speed signal transmission: High-speed signal transmission in multilayer PCBs requires higher-level technologies, such as differential signal transmission, impedance matching, etc., to ensure signal stability and reliability.

Electromagnetic compatibility: The circuit components in the multilayer PCB are becoming more and more dense, and the electromagnetic interference is becoming more and more serious, and effective electromagnetic compatibility technologies such as shielding, ground wire processing, etc., are required to ensure the normal operation of the circuit components.

In summary, the production of 12-layer rigid-flex PCBs is a high-end technology that can provide better electrical and mechanical properties, and is suitable for electronic devices that require high performance, high reliability, high integration, and high flexibility.

Make Your PCB Dreams a Reality with XPCB Limited

XPCB Limited is your go-to partner for turning your PCB dreams into reality. Our streamlined PCB manufacturing process, combined with quick-turnaround prototyping and turnkey PCBA services, ensures that your projects come to life with ease. Trust in our expertise and dedication to quality as we help you achieve your PCB goals. Join us and experience the difference with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve