- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

The two main reasons for the warping of rigid PCB are: 1. The substrate storage method is incorrect, 2. The improper production operation causes the warping, for these two problems, it is still possible to avoid them as long as you observe carefully, this chapter mainly focuses on the problem of warping of rigid PCBs to do a detailed explanation!

Storage: Because the copper-clad laminate will increase warpage due to moisture absorption during storage, the single-sided copper-clad laminate has a large moisture-absorbing area. If the inventory environment humidity is high, the single-sided copper-clad laminate will greatly increase the warpage. The moisture of the double-sided copper-clad laminate can only penetrate from the end face of the product, the moisture absorption area is small, and the warpage changes slowly.

For copper-clad laminates without moisture-proof packaging, attention should be paid to warehouse conditions to minimize humidity in the warehouse and to avoid exposed copper-clad laminates to avoid warping of copper-clad laminates during storage. Improper placement of copper-clad laminates will increase warpage, vertical placement on copper-clad laminates or heavy objects, poor placement, etc. will increase the warpage of copper-clad laminates.

For PCB rigid boards, it is also necessary to pay attention to the anti-interference ability of the whole board, and the conventional methods are:

Since the printed solder paste does not solder the PCB assembly board and cannot fix the electrical test end of the thermocouple, it is necessary to use the actual soldered product for testing. The test temperature does not exceed the limit temperature, and the assembled board can be used as a formal product after testing 1 to 2 times (the test board cannot be used repeatedly and more than 2 times). After long-term high-temperature welding, the color of the multi-layer board will change from light to dark or yellowish-brown.

Although the heating method of the all-hot blast stove is mainly convective conduction, there is also a small amount of radiation conduction. Dark brown absorbs more heat than a regular light green PCB, so the measured temperature will also be slightly higher than the actual temperature.

So how to quickly test the temperature curve of 16-layer rigid PCB, and what are the specific methods and steps?

Your Trusted Partner for PCB Success: XPCB Limited

Let XPCB Limited be your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

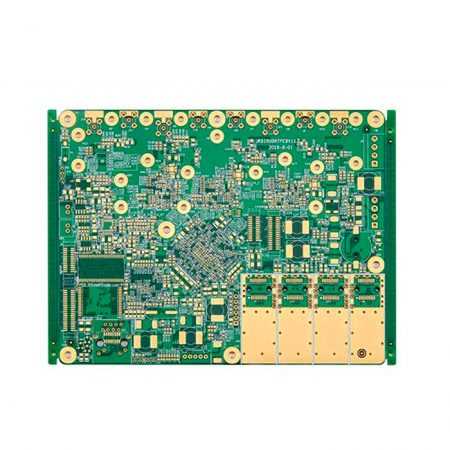

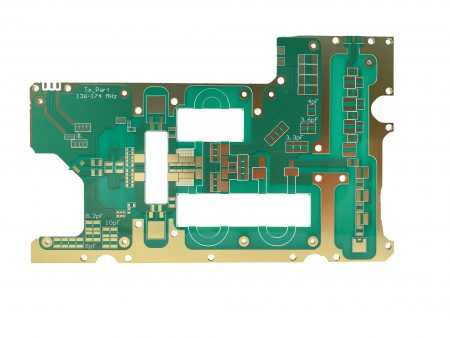

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve