- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Material selection: choose high-strength, high-rigidity rigid circuit board materials, such as fiberglass plates, ceramic plates, etc. Use reinforcement materials: When designing, you can add reinforcement materials to the bottom of the board to increase the strength of the board surface. Hot pressing treatment: Use a hot press machine to heat press the shape of the circuit board under the action of high temperature and high pressure to avoid warping. Use multi-layer boards: Multi-layer boards are stronger than single-layer boards, which reduces the possibility of warpage.

Use Plate Supports: Add plate supports underneath the board to increase the stability of the board surface. Use nickel metallization: During the manufacturing process, nickel metallization treatment is used to increase the mechanical strength and stability of the circuit board.

Thickness control: Controls the thickness of the rigid circuit board to ensure that it is rigid enough. Use substrates with consistent thickness: Differences in the thickness of substrates can cause board warping, so using substrates with consistent thickness can reduce the risk of warpage. Control the soldering temperature: When soldering the circuit board, it is necessary to control the soldering temperature to avoid the deformation of the rigid circuit board caused by excessive temperature.

Fix with brackets: When using the board, you can use brackets or fixing clips to hold the board in place to avoid warping due to mechanical vibration and other reasons. Manual bending correction: If the circuit board has already warped, you can use the manual bending method to correct it, but pay attention to the force and angle to avoid damaging the circuit board.

Copper foil thickness: Increase the thickness of copper foil appropriately to enhance the strength of the plate. Use metal foil reinforcement: When designing a rigid circuit board, you can add metal foil reinforcement at the board’s edge to increase the board’s strength and stability and prevent warping. Control the moisture content of the board: When manufacturing the circuit board, it is necessary to control the moisture content of the board to avoid the deformation of the circuit board due to excessive moisture content.

Use consistent copper foil thickness: Inconsistent copper foil thicknesses for circuit boards can also cause warpage, so use copper foil with consistent thickness. For large areas of copper foil, an isolation layer can be added underneath it to reduce the possibility of warping. Pay attention when installing the circuit board: When installing the circuit board, avoid over-tightening the screws or fixtures to avoid warping the circuit board.

Cabling planning: Reasonable design of wiring planning to avoid local over-density or over-concentration, resulting in uneven pressure on the board surface.

PCB design: When designing the PCB shape, avoid overly complex geometries to avoid uneven force on the board surface. When designing, increase the drilling diameter appropriately to avoid the deformation of the circuit board caused by too small the drilling.

Reinforced supports: Reinforced supports around or at critical points of the board to increase the overall rigidity of the board.

Control soldering temperature and ambient temperature: Control soldering temperature and time to avoid deformation of circuit board caused by excessive temperature or too long time. In the process of manufacturing, assembly and use, the ambient temperature should be controlled as much as possible to avoid excessive or low temperatures that have adverse effects on the circuit board.

Use brackets: During the manufacturing process, pressure plates are used to compact the circuit board to keep the board surface flat. When assembling, use brackets or fixtures to avoid deformation caused by uneven force on the plate surface. In the process of transportation and storage, strengthen the packaging of the circuit board to avoid the impact of external force on the board surface.

Regular inspection: Regularly check the status of the circuit board, and find and deal with the warpage problem of the board in time.

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limitedby your side.

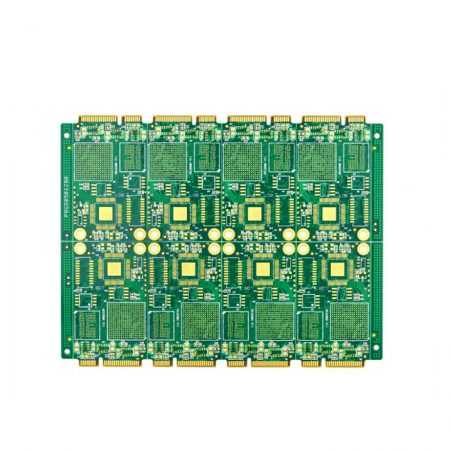

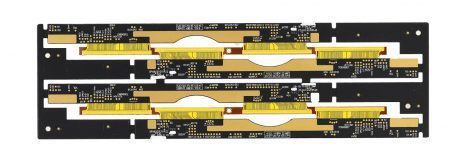

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve