- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

With the continuous pro-pro products in the electronics industry, multi-layer circuit boards are favored to a large extent, for some high-frequency multi-layer boards, all the VIA holes at the BGA in the board. The solder mask double-sided has to make the gear point, and can not make plug holes, PCB plug holes are generally after the ground solder mask layer, and then the second layer of ink is used to fill the heat dissipation holes below 0.5mm.

(1) When DIP on the parts, avoid the tin pot when the tin pot penetrates and the connection causes a short circuit in the line.

(2) Maintain the surface flatness of the PCB board, and the characteristic impedance requirements to meet the customer’s requirements;

(3) Avoid damage to the line. XPCB Limited can provide two types of plugging services according to customer requirements: “resin plugging” and “electroplating filling”, resin plugging refers to: The use of solvent-free ink plugging, in addition to solving the problem of making up for the general ink is not easy to fill, but also can reduce the “crack” problem of ink production when heated.

Electroplating hole filling uses the characteristics of additives to control the production speed of each part of the copper for hole filling operation, which is mainly used in the production of some continuous multi-layer laminated hole boards or high-current PCB board design.

(1) Avoid flux residue in the via, causing blockage;

(2) Prevent the solder bead from popping out during wave soldering to avoid short circuit of the line;

(3) Prevent the surface tin from flowing into the hole, causing tiger welding, which affects the final placement effect;

(4) After the surface mounting is completed with components, the PCB board needs to be tested on the testing machine, and only the vacuum suction to form a negative pressure is considered qualified.

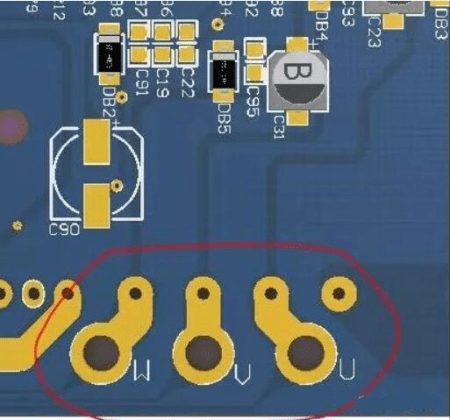

Before understanding what PCB solder mask opening, let’s first learn what solder mask layer refers to! The so-called PCB solder mask layer refers to the part of the printed circuit board that needs to be green oil, and PCB solder mask window refers to the copper skin on the pad can not be covered by solder mask ink, but must leak out of the board;

If it is a double-sided circuit board in the design, both sides of the board will be printed with a solder mask, the role of this layer of ink is to prevent the oxidation of the circuit board to play a protective role. And facilitate the follow-up SMT soldering convenience.

PCB solder mask open refers to the circuit board around the aperture around the copper sheet shall not be covered by ink. If the solder mask is covered, it will not be able to measure the corresponding signal, only the aperture copper leakage on the surface, in order to effectively increase the thickness of the trace and increase the current limit.

1: Liquid photosensitive ink: Liquid photosensitive ink is a special ink, which can be printed on a full plate without a printing plate. The ink coating can be cured by light, and after development, it can be processed with etching, electroplating, electrophoresis and coloring, etc., which is suitable for the production of small batches, multiple varieties, personalized and high-precision products.

2: UV solder mask ink: Suitable for manufacturing rigid printed circuit board solder mask pattern, fast light fixing speed, good heat resistance, strong adhesion, can meet the requirements of single-sided and double-sided circuit boards. If the viscosity is very large, you can add a small amount of special diluent to dilute, but the dosage shall not exceed 5% of the amount of ink.

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve