- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

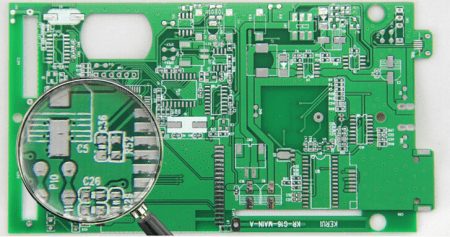

This article will introduce in detail the function of PCB circuit board, source, development, classification, composition, appearance, advantages, characteristics, PCB circuit board soft and hard difference, the basic knowledge of pcb circuit boards.

Introduction to PCB Circuit Board

PCB, printed circuit board for short, is one of the important parts of the electronic industry at present. Mainly use insulating board as the base material, cut into appropriate size. Attach a conductive pattern with holes (such as component holes, fastening holes, metallized holes, etc.) to replace the chassis of the previously equipped electronic devices and realize the interconnection between the electronic components. The board is made using electronic printing and is also called a “printed” circuit board.

Almost all electronic equipment, from electronic watches, calculators, to computers, communication electronic equipment, military weapon systems, as long as there are electronic components such as integrated circuits, as long as the parts that need electrical interconnection, all need to use pcb lines. In the process of relatively large-scale electronic product research, the most basic success factor is the design, documentation and manufacturing of the product. The design and manufacturing quality of PCB also directly affects the quality and cost of the entire product, and even leads to the success or failure of commercial competition.

First: Function of PCB

After electronic equipment uses PCB, due to the consistency of similar PCB, manual wiring errors can be effectively avoided, and electronic components can be automatically inserted or mounted, automatic soldering, and automatic detection, ensuring the quality of electronic equipment, which improves labor productivity, reduces costs, and is also conducive to later maintenance.

Second: Source of PCB

The creator of the PCB is the Austrian Paul Eisler (Paul Eisler), in 1936, he first used the PCB circuit board in the radio. In 1943, Americans mostly used this technology for military radios. In 1948, the United States officially approved this invention for commercial use. Since the mid-1950s, PCBs have only begun to be widely used.

Before the advent of PCB boards, the interconnection between electronic components was done directly by wires. Nowadays, wires are only used for experimental applications in the laboratory. PCB circuit boards have definitely occupied a position of absolute control in the electronics industry.

Third: Development of PCB

PCB boards have developed from single-sided to double-sided, multi-sided and flexible, and still maintain their own development trends. Due to the continuous development of high precision, high density and high reliability, continuous reduction in size, cost reduction, and performance improvement, PCB boards still maintain a strong vitality in the development of electronic equipment in the future.

Summarizing the domestic and foreign discussions on the development trends of PCB production and manufacturing technology in the future are basically the same, that is, towards high density, high precision, fine aperture, fine wire, fine pitch, high reliability, multilayer, high-speed transmission, light weight, The development of thin type, in the production, at the same time, to increase productivity, reduce costs, reduce pollution, and adapt to the development of multi-variety, small-batch production. The technical development level of the printed circuit boards is generally represented by the line width, aperture, and board thickness/aperture ratio on the PCB circuit board.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve