- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

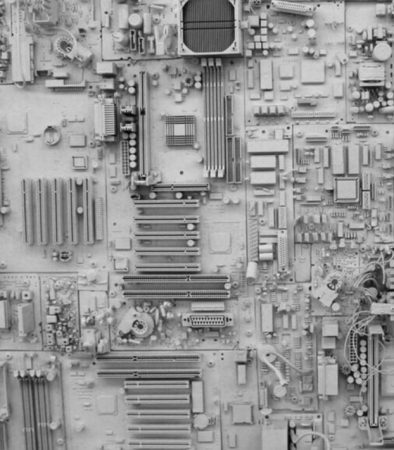

SMT is the English abbreviation of Surface Mounting Technology, which means surface mount technology in Chinese. SMT is a new generation of electronic assembly technology, and it is also the most popular technology and process in the electronic assembly industry. It compresses traditional electronic components into a few tenths of the volume. The PCB blank board has no function, and only through SMT can the circuit have a functional effect. Raw materials of PCB: Copper-clad laminate is the substrate material for making printed circuit boards, which is not only used to support various components but also to achieve electrical connection or electrical insulation between them.

A PCB is a printed circuit board (PCB), which is simply a thin board containing integrated circuits and other electronic components. It can be found in almost every electronic device. If there are electronic parts in a device, they are all embedded in PCBs of various sizes. In addition to fixing various small parts, the main function of the PCB is to provide the electrical connection of the various parts on the top.

Surface mount is not a new concept, it has its roots in older processes such as flush mount and hybrid mounting. The assembly of electronic circuits was initially based on a point-to-point wiring method, and there was no substrate at all. The packaging of the first semiconductor device Radial pins are inserted into the through-holes of monolithic circuit boards that have been used for resistor and capacitor packaging.

Image 1: SMT history

In the 50s, flat-mounted surface-mount elements were used in the highly reliable military, in the 60s, hybrid technology was widely used, in the 70s, under the influence of Japanese consumer electronics, passive components were widely used, and in the last decade, active components were widely used. Surface Mount Technology (SMT) is a widely used alternative to older through-hole (TH) printed circuit board design and production practices. While TH manufacturing still has a place, SMT basically takes over considerations in terms of size, weight, and automated production processes.

SMT includes the use of surface-mounted devices (SMDs) to replace larger, heavier, and more cumbersome counterparts for through-hole PCB construction. Today more and more PCB equipment is available in SMD or packages, making it practical and cost-effective to design and produce SMT boards.

Due to the nature of SMT board construction and smaller, lighter components, the automated construction of PCBs is facilitated and the manufacturing industry becomes very effective, especially for mass production. To obtain the most important advantages in manufacturing, SMT construction must be as highly mechanized as possible.

The assembly density is high, the electronic products are small in size and light in weight, and the volume and weight of SMD components are only about 1/10 of the traditional plug-in components. Generally, after the use of SMT, the volume of electronic products is reduced by 40%~60%, and the weight is reduced by 60%~80%. SMT products have high reliability, strong vibration resistance, low solder joint defect rate, good high-frequency characteristics, and reduce electromagnetic and radio frequency interference.

Image 2: surface mount technology PCBA service

Reliability enhancement due to the absence of required conformance components resulting in subsequent welding of small holes in place. Welding SMD surface pads is simpler and faster, reducing assembly time while improving quality. And it is easy to realize automation and improve production efficiency. Reduce the cost by 30%~50%. Save materials, energy, equipment, manpower, time, etc.

Machining with drilled through-holes requires careful alignment, often resulting in pre-adaptation to specific PCB layouts and component locations. SMT assembly can eliminate most of the SMD placement interventions, allowing for more automation and thus reducing costs. SMD small leaders, or maybe none at all.

Image 3: SMT Placement Machine

Your Trusted Partner for PCB Success: XPCB Limited

Let XPCB Limited be your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve