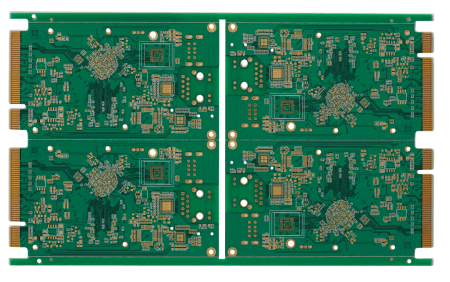

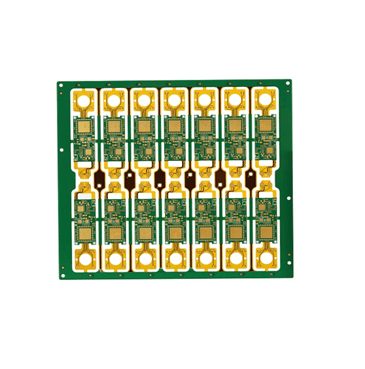

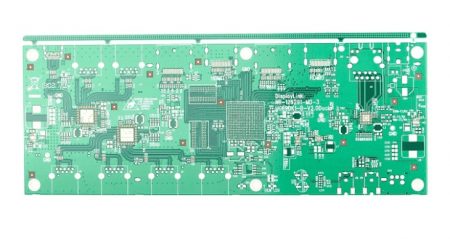

HDI rigid PCBs (High-Density Interconnector PCBs) are high-performance printed circuit boards (PCBs) that offer increased wiring density and improved functionality. These PCBs are widely used in various industries due to their unique features and advantages. This document will provide a brief overview of HDI rigid PCBs, their manufacturing process, and their commonly used applications

A HDI rigid PCB is a type of PCB that employs advanced fabrication techniques to achieve higher wiring densities with smaller components. Unlike traditional PCBs, HDI PCBs have smaller vias and trace widths, allowing for increased signal integrity and reduced signal loss. This increased wiring density allows for the integration of more complex and miniaturized electronic circuits, resulting in smaller and more efficient electronic devices.

The manufacturing process of HDI rigid PCBs involves several steps to ensure the quality and integrity of the boards. The following steps are typically followed:

HDI rigid PCBs find a wide range of applications in various industries, including:

– Consumer Electronics: HDI PCBs are used in smartphones, tablets, and other portable electronic devices that require miniaturization and high performance.

– Automotive: HDI PCBs find applications in automotive electronics, such as infotainment systems, navigation systems, and hybrid electric vehicles.

– Healthcare: PCBs are utilized in medical devices, such as ultrasound machines, pacemakers, and medical imaging systems.

– Aerospace and Defense: HDI rigid PCBs are used in aerospace and defense applications, such as fighter jets, satellite systems, and military communication systems.

– Industrial Automation: PCBs are employed in industrial automation systems, such as robots, control systems, and CNC machines.

– Telecommunication: HDI rigid PCBs are widely used in telecommunications infrastructure, including routers, switches, and base stations.

HDI rigid PCBs offer significant advantages in terms of increased wiring density, improved signal integrity, and reduced size. With their advanced manufacturing process and wide range of applications, they are becoming increasingly important in various industries. As technology continues to advance, HDI rigid PCBs are expected to play a significant role in the development of smaller, faster, and more reliable electronic devices.

Make Your PCB Dreams a Reality with XPCB Limited

XPCB Limited is your go-to partner for turning your PCB dreams into reality. Our streamlined PCB manufacturing process, combined with quick-turnaround prototyping and turnkey PCBA services, ensures that your projects come to life with ease. Trust in our expertise and dedication to quality as we help you achieve your PCB goals. Join us and experience the difference with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : info@x-pcb.com

© 2024 - XPCB Limited All Right Reserve