As the demand for electronic devices continues to surge, the importance of efficient and reliable PCB (Printed Circuit Board) assembly equipment cannot be overstated. In 2024, the landscape of PCB assembly is evolving rapidly, driven by advancements in technology, the need for higher efficiency, and a growing emphasis on sustainability. This comprehensive guide explores the key types of PCB assembly equipment, emerging trends, and considerations for businesses looking to optimize their assembly processes.

PCB assembly involves multiple processes that transform raw PCBs into fully functional electronic products. The essential equipment used in this process includes:

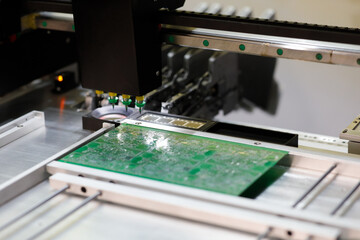

Pick-and-Place Machines: These machines automate the placement of surface-mounted devices (SMDs) onto PCBs. They are crucial for achieving high-speed and high-precision assembly, reducing manual labor, and minimizing errors.

Solder Paste Printers: These printers apply solder paste to the PCB pads before components are placed. A high-quality solder paste printer ensures accurate application, which is critical for reliable solder joints.

Reflow Ovens: After component placement, PCBs enter reflow ovens where solder paste is melted to create permanent electrical connections. These ovens must provide precise temperature control to prevent damage to sensitive components.

Wave Soldering Machines: For through-hole components, wave soldering machines are essential. They create a wave of molten solder that the PCB passes through, ensuring all connections are properly soldered.

Automated Optical Inspection (AOI) Systems: These systems inspect PCBs after assembly to detect defects such as misaligned components or insufficient solder. AOI helps maintain quality control and reduces rework.

X-Ray Inspection Systems: For more complex assemblies, particularly those with hidden solder joints, X-ray inspection provides a non-destructive means to check the integrity of solder connections.

In 2024, several trends are shaping the PCB assembly equipment market:

Smart Manufacturing and IoT Integration: The move towards Industry 4.0 is making smart manufacturing more prevalent in PCB assembly. Equipment equipped with IoT capabilities allows for real-time monitoring, data collection, and predictive maintenance, leading to improved efficiency and reduced downtime.

Sustainability: As environmental concerns grow, manufacturers are increasingly focusing on sustainable practices. This includes the use of eco-friendly materials, energy-efficient machines, and processes that minimize waste. Equipment that can handle lead-free solder and other green materials is becoming more essential.

Increased Automation: Automation continues to be a significant trend, with advancements in robotics and artificial intelligence streamlining assembly processes. Fully automated assembly lines can improve throughput and consistency while reducing labor costs.

Miniaturization and High-Density Interconnects: The trend towards smaller, more compact electronic devices requires assembly equipment capable of handling micro-components and high-density interconnects (HDI). Equipment designed for precision and adaptability is crucial to meet these demands.

When selecting PCB assembly equipment, several factors should be taken into account:

Production Volume: Determine the scale of production. High-volume manufacturers may benefit from fully automated systems, while smaller operations might opt for semi-automated solutions.

Component Types: Consider the types of components being used. Ensure the equipment can handle both SMD and through-hole components, as well as any unique specifications for micro-components.

Flexibility and Scalability: As technology evolves, businesses may need to adapt to new products and changing market demands. Choose equipment that offers flexibility in setup and can easily scale as production needs grow.

Technical Support and Training: Evaluate the level of support offered by the equipment supplier. Comprehensive training and accessible technical support are essential for minimizing downtime and ensuring effective use of the equipment.

Budget: While investing in high-quality equipment is crucial, it’s also important to consider the total cost of ownership, including maintenance, operation costs, and potential savings through improved efficiency.

The future of PCB assembly equipment is bright, with continuous advancements expected in technology and processes. As manufacturers strive for greater efficiency and sustainability, the industry will likely see more innovations in automation, smart technology integration, and eco-friendly practices.

In conclusion, the landscape of PCB assembly equipment in 2024 is characterized by technological advancements, a focus on sustainability, and the ongoing push for automation. Understanding the various types of equipment, emerging trends, and key considerations will empower manufacturers to make informed decisions that enhance their production capabilities. By embracing these innovations, businesses can position themselves for success in the ever-evolving electronics market.

Make Your PCB Dreams a Reality with XPCB Limited

XPCB Limited is your go-to partner for turning your PCB dreams into reality. Our streamlined PCB manufacturing process, combined with quick-turnaround prototyping and turnkey PCBA services, ensures that your projects come to life with ease. Trust in our expertise and dedication to quality as we help you achieve your PCB goals. Join us and experience the difference with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : info@x-pcb.com

© 2024 - XPCB Limited All Right Reserve