- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

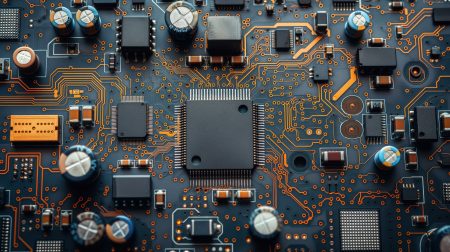

Prototyping is a critical phase in the production of printed circuit board assemblies (PCBAs), where the quality of soldering directly impacts the functionality and reliability of the final product. Incomplete soldering can lead to a host of issues, including electrical failures and reduced lifespan of the device. Understanding the common causes of incomplete soldering during PCBA prototyping is essential for achieving optimal results. Here, we will explore several key factors that contribute to this problem and provide insights on how to mitigate them.

The quality of solder paste plays a pivotal role in ensuring adequate soldering. If the solder paste is of poor quality—due to improper storage conditions, expired shelf life, or incorrect viscosity—it may not adhere properly to the PCB pads. Low-quality paste can result in insufficient solder application, leading to cold solder joints or incomplete coverage. To avoid this issue, always use high-quality solder paste and check the expiration date and storage conditions before use.

The solder paste printing process is crucial for achieving uniform application on the PCB. Several issues can arise during this stage:

Incorrect Printing Speed: If the printing speed is too fast, the paste may not fill the pads adequately, resulting in incomplete solder joints.

Inconsistent Pressure: Uneven pressure applied during the printing process can lead to inconsistent paste thickness across the board.

To improve the printing process, calibrate your printing equipment regularly and conduct tests to find the optimal speed and pressure settings.

The stencil used for applying solder paste must be designed correctly to match the PCB layout. Stencil apertures that are too small or incorrectly shaped can hinder the flow of solder paste, resulting in insufficient application. Additionally, a worn or damaged stencil can also lead to poor printing results. To address these issues, ensure that the stencil design matches the PCB specifications and replace any damaged stencils promptly.

Accurate placement of components on the PCB is essential for successful soldering. Misalignment can lead to poor solder joints, especially with fine-pitch components. Additionally, if components are not seated properly, solder paste may not make adequate contact, causing incomplete soldering. Utilize automated pick-and-place machines and conduct visual inspections to ensure proper alignment and placement of all components.

Reflow soldering is a critical step that influences the quality of solder joints. Incomplete soldering can occur if:

Temperature Profile is Incorrect: If the reflow oven’s temperature profile is not optimized, it may not allow the solder paste to reach the necessary melting point, leading to inadequate solder joints.

Insufficient Time: If the soldering time is too short, the solder may not have enough time to properly flow and adhere to the pads.

To avoid these issues, regularly monitor and adjust the temperature profile of the reflow oven based on the solder paste specifications and the components used.

Environmental conditions, such as humidity and temperature, can significantly impact soldering quality. High humidity can cause solder paste to absorb moisture, leading to “solder balls” or other defects. Conversely, extremely low temperatures can affect the flow characteristics of the solder. Maintaining a controlled environment during the prototyping phase is essential. Utilize climate control systems to regulate humidity and temperature in the production area.

The surfaces of both the PCB and components must be clean and free from contaminants to ensure proper adhesion of solder. Oils, dust, or oxidation can create barriers that prevent solder from forming a solid joint. Always clean PCBs and components before soldering and consider using surface treatments, such as immersion gold or ENIG, to enhance solderability.

Consigned Assembly: A Cost-Effective Option for Small Businesses

Incomplete soldering during PCBA prototyping can lead to significant problems down the line, including product failures and increased production costs. By understanding the common causes of incomplete soldering and implementing effective solutions, manufacturers can enhance the quality and reliability of their PCBAs. Continuous improvement in soldering processes, equipment calibration, and environmental control will ultimately contribute to a successful prototyping phase and, ultimately, a superior final product.

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve