- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

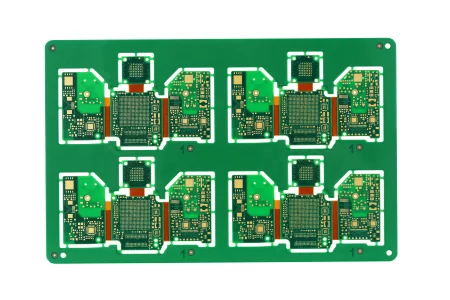

Rigid-flex PCBs, which combine the benefits of rigid and flexible circuit boards, are increasingly prevalent in various industries due to their unique design capabilities. These innovative circuit boards offer enhanced reliability, space-saving advantages, and improved performance, making them ideal for numerous applications. In this blog, we will explore the key applications of rigid-flex PCBs across different sectors.

One of the most prominent applications of rigid-flex PCBs is in consumer electronics, including smartphones, tablets, and wearable devices like smartwatches. The compact nature of these devices demands efficient use of space, and rigid-flex technology allows for intricate designs that maximize the internal layout. By integrating rigid and flexible sections, manufacturers can reduce the number of connectors and solder joints, enhancing durability and reliability. This flexibility also enables unique form factors that can conform to the ergonomic designs desired by consumers.

In the medical field, the reliability and miniaturization of devices are paramount. Rigid-flex PCBs are widely used in portable diagnostic tools, monitoring equipment, and surgical instruments. These boards can withstand the rigors of medical applications while maintaining high performance. For instance, they can be found in wearable health monitors that track vital signs or in advanced imaging equipment. The ability to integrate multiple functionalities within a compact design helps ensure that medical devices are not only efficient but also easy to use and transport.

The aerospace industry demands the highest levels of reliability and performance due to the critical nature of its applications. Rigid-flex PCBs are particularly valuable in this sector, where weight savings and durability are crucial. These boards are used in avionics systems, communication devices, and flight control systems. The reduction in the number of connections minimizes potential failure points, and their resistance to vibration and extreme environmental conditions makes them suitable for the harsh realities of flight. By utilizing rigid-flex technology, manufacturers can create lighter and more reliable systems that meet strict regulatory standards.

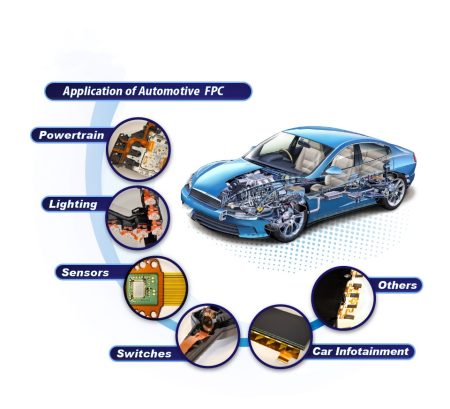

As vehicles become increasingly equipped with advanced electronics, rigid-flex PCBs are finding their way into automotive applications. These boards are used in dashboard displays, navigation systems, and various sensor technologies. The automotive industry benefits from the space-saving attributes of rigid-flex designs, which allow for more compact and efficient layouts. Moreover, the enhanced durability of these boards ensures they can withstand the demanding conditions present in vehicles, such as temperature fluctuations and mechanical stress.

In industrial settings, rigid-flex PCBs play a vital role in control systems and robotics. These applications often require boards that can operate effectively in confined spaces while providing reliable electrical performance. The flexibility of rigid-flex designs allows them to be integrated into robotic arms and automated machinery, where traditional rigid boards might not fit. This adaptability not only improves the functionality of industrial equipment but also contributes to the overall efficiency of manufacturing processes.

The rise of smart home technology has created a significant demand for compact, high-performance circuit boards. Rigid-flex PCBs are ideal for applications such as smart locks, security cameras, and home automation controllers. These devices benefit from the reduced size and weight provided by rigid-flex technology, enabling sleek and modern designs that appeal to consumers. Additionally, the reliability of these boards ensures consistent performance in everyday home environments.

The applications of rigid-flex PCBs are vast and varied, demonstrating their versatility across multiple industries. From consumer electronics to medical devices, aerospace, automotive, industrial equipment, and smart home technologies, rigid-flex PCBs offer unique advantages that enhance performance, reduce space, and improve reliability. As technology continues to advance, the demand for innovative solutions like rigid-flex PCBs will grow, paving the way for new possibilities in design and functionality. With their ability to meet the challenges of modern electronics, rigid-flex PCBs are set to play an increasingly vital role in shaping the future of various applications.

Take Your Projects to New Heights with XPCB Limited

XPCB Limited offers top-notch PCB manufacturing, quick-turnaround prototyping, and turnkey PCBA services designed to make your projects shine. Count on us to bring your ideas to life with efficiency and quality. Your success matters to us, and we’re here to make your innovation journey smooth and rewarding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve