- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

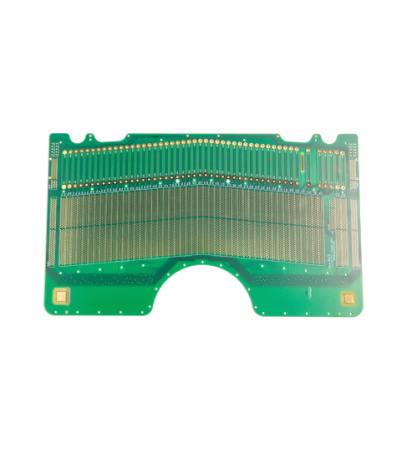

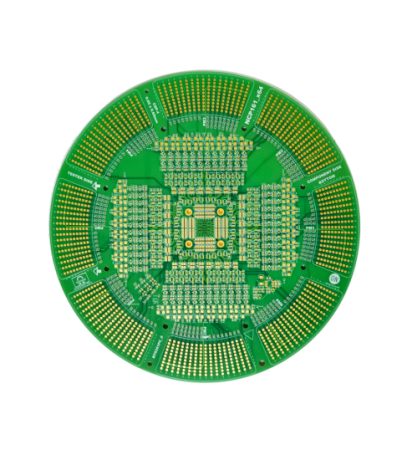

Virtual Reality (VR) technology has revolutionized the way we experience digital content, creating immersive experiences for gaming, training, entertainment, and more. Behind the scenes of these advanced systems, a crucial component that enables VR devices to function seamlessly is the Printed Circuit Board (PCB). PCBs serve as the backbone of all electronic components, providing the electrical connections that allow various parts of the device to communicate. In this blog, we’ll explore the types of PCBs needed for VR devices, their functions, and the challenges designers face when developing them.

At the heart of any VR device, whether it’s a VR headset or controller, is the motherboard. This is the central PCB that houses the primary processing units like the CPU, GPU, memory, and power management circuits. The motherboard controls the overall functionality of the device, including processing input from sensors, managing power, and rendering complex graphics.

Key Features: High-speed signal transmission, multi-layer design to minimize interference, and efficient power distribution.

Challenges: The motherboard needs to handle real-time processing of high volumes of data from various sensors (like motion tracking) while ensuring minimal latency, as any delay can disrupt the immersive experience of VR.

A VR headset’s display is one of its most critical components. Whether using OLED, LCD, or microLED technology, these displays require a display driver PCB to convert graphic signals from the device’s main processor to the display screen.

Key Features: Fast data throughput, high-refresh rates (at least 90Hz, often higher), and high-definition signal processing.

Challenges: Displays in VR headsets need to work at ultra-low latency to ensure that the user’s experience feels immersive and fluid. If the display lags, it can cause nausea and motion sickness.

Modern VR systems rely heavily on sensors to track the user’s head, hand, and body movements. These sensors are often integrated into small, specialized PCBs, which include accelerometers, gyroscopes, magnetometers, and cameras for positional tracking.

Key Features: Precision in motion sensing, ultra-low latency, and the ability to handle large amounts of real-time data.

Challenges: Accurate tracking is crucial in VR, as even small inaccuracies can break immersion. The PCB must provide noise immunity and support fast data transfers to ensure that the sensor data can be processed in real-time.

Due to the complex and power-hungry nature of VR systems, power management is a critical component. Power management PCBs handle everything from distributing power to various components to managing the charging and discharging of batteries, especially in wireless VR devices.

Key Features: High-efficiency power conversion, thermal management, and integrated battery management systems (BMS).

Challenges: Managing power in VR headsets involves balancing between long battery life and high performance. Wireless VR systems, in particular, require power-efficient designs that can last for several hours while maintaining performance.

Wireless VR headsets are increasingly popular, and they rely on wireless communication PCBs for data transmission between the headset and a connected device like a gaming PC or console. These boards typically use technologies like Wi-Fi, Bluetooth, or proprietary communication protocols for data transfer.

Key Features: Low-latency data transfer, high bandwidth to handle VR data streams (such as video and sensor data), and power efficiency.

Challenges: Minimizing interference is vital, as VR systems require a constant stream of data. Wireless communication PCBs must support high-throughput without causing delays that could break immersion.

Many VR experiences include 3D audio to enhance the sense of immersion. Audio PCBs manage sound input and output, either through speakers, headsets, or microphones, allowing for realistic spatial audio.

Key Features: High-fidelity audio signal processing, noise reduction, and compatibility with immersive audio technologies like surround sound.

Challenges: Audio latency must be minimal, as any delay between visual and auditory cues can disrupt the VR experience. Additionally, VR audio systems must be able to deliver high-quality sound without adding significant bulk or weight to the headset.

Haptic feedback is an essential feature of many VR devices, especially in controllers or wearable devices that provide tactile responses to user actions. A haptic feedback PCB drives motors or actuators to simulate sensations like vibrations or forces.

Key Features: Responsive to user input, precise control of feedback strength and direction, and minimal latency.

Challenges: Ensuring the feedback is synchronized with the visual experience is crucial. Poorly timed feedback can create a jarring experience, so the PCB needs to process input data quickly and precisely.

The development of VR devices requires a range of specialized PCBs, each designed to meet the unique needs of the hardware they support. From the main motherboard that coordinates all operations to the sensor boards that track movement and the wireless boards that enable communication, every PCB plays a critical role in ensuring a seamless and immersive VR experience.

Designing these PCBs is no small feat: it requires overcoming challenges like reducing latency, managing power, and optimizing data throughput, all while keeping the device lightweight and comfortable for users. As VR technology continues to evolve, so too will the innovation in PCB design, ensuring that future VR systems can deliver even more realistic and engaging experiences.

Take Your Projects to New Heights with XPCB Limited

XPCB Limited offers top-notch PCB manufacturing, quick-turnaround prototyping, and turnkey PCBA services designed to make your projects shine. Count on us to bring your ideas to life with efficiency and quality. Your success matters to us, and we’re here to make your innovation journey smooth and rewarding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve