- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In the fast-evolving world of electronics, the demand for small-batch, high-precision, and customized Printed Circuit Board Assemblies (PCBA) has skyrocketed. As technology becomes more advanced, industries ranging from consumer electronics and medical devices to automotive and IoT are seeking highly specialized PCBA solutions that meet specific requirements in performance, size, and functionality. One company that has proven to be at the forefront of this shift is XPCB Limited. In this blog, we’ll explore how XPCB Limited has adapted its operations to meet the market’s growing demand for these specialized PCBAs.

In the traditional PCB assembly industry, large-volume production runs were the norm. However, today’s market is increasingly demanding small batches, particularly for prototyping, new product development, and industries requiring rapid innovation cycles. This shift is especially evident in sectors like medical devices, automotive electronics, and wearable technology, where custom designs often need to be tested in limited quantities before mass production.

XPCB Limited has positioned itself as an expert in small-batch production, offering efficient and cost-effective solutions for low-volume orders. Their state-of-the-art manufacturing facilities and flexible production capabilities allow them to handle short runs without compromising on quality or turnaround time. By utilizing advanced automation and skilled technicians, XPCB ensures that each small batch is assembled with the same attention to detail as larger orders, maintaining consistency and performance across every unit.

The key to XPCB’s success in small-batch production lies in its ability to provide fast turnarounds without sacrificing precision. With their streamlined production processes, XPCB can meet tight deadlines while maintaining high-quality standards, helping companies bring their innovations to market quickly.

As technology becomes more complex, so does the need for high-precision PCBA solutions. Whether it’s for high-frequency circuits, miniaturized components, or dense circuit layouts, the demand for precision has never been higher. XPCB Limited recognizes that in many industries—especially in aerospace, automotive, and medical electronics—there is no room for error.

To meet these precision demands, XPCB employs a combination of cutting-edge technologies and highly skilled engineers. The company utilizes automated pick-and-place machines capable of placing components with micron-level accuracy. Additionally, advanced optical inspection and X-ray inspection techniques are employed to detect any potential defects or misalignments, ensuring that every component is correctly placed and soldered.

XPCB’s dedication to high-precision assembly extends to its materials as well. By sourcing high-quality components and utilizing top-tier fabrication processes, the company ensures that each PCBA meets the most stringent industry standards. This precision not only improves the functionality and durability of the final product but also enhances the overall performance, especially in high-tech sectors that require perfect signal integrity and minimal interference.

As the electronics market becomes more diverse, the demand for customized PCBA solutions has increased. Businesses no longer simply want off-the-shelf PCBs; they require assemblies that are tailored to meet specific technical specifications and design parameters. This could mean incorporating unique components, designing unconventional form factors, or adapting to niche industry needs.

XPCB Limited has made a name for itself by offering custom PCBA solutions for a wide range of applications. From highly specialized automotive PCBs to bespoke wearable devices, XPCB works closely with its clients to understand their requirements and provide tailored solutions. Their design-for-manufacturability approach ensures that all custom PCBs are not only feasible to produce but also cost-effective.

XPCB’s expert engineering team collaborates with clients from the initial stages of the design process, providing guidance on material selection, circuit layout optimization, and best practices for assembly. This close collaboration allows for greater flexibility in meeting specific customer needs and ensures that the final product is fully customized to meet both functional and aesthetic requirements.

Moreover, XPCB’s rapid prototyping capabilities allow clients to test and validate their designs quickly, making it easier to iterate on custom solutions without long lead times. This flexibility is a key competitive advantage, especially in industries like consumer electronics and medical technology, where innovation cycles are shorter than ever.

In today’s fast-paced electronics market, the need for small-batch production, high-precision assembly, and customized solutions is growing. XPCB Limited has adapted to these demands by combining cutting-edge technology with expert engineering and a customer-first approach. By offering flexible, cost-effective, and high-quality PCBA solutions, XPCB continues to empower industries across the globe to innovate faster and more efficiently. As technology continues to evolve, XPCB’s ability to meet these specialized demands will only become more critical, solidifying its position as a leader in the PCBA industry.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

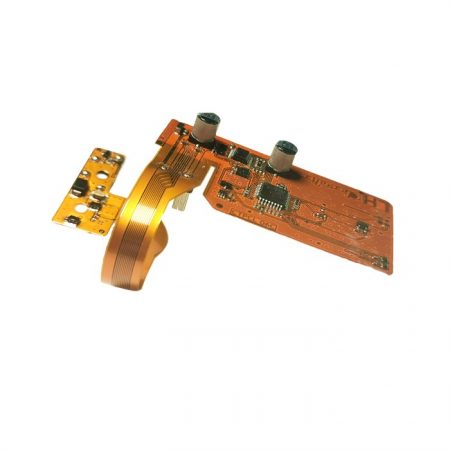

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve