- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Black Friday is one of the most critical sales events of the year, driving huge spikes in demand across multiple industries, particularly in consumer electronics and tech products. For PCBA (Printed Circuit Board Assembly) manufacturers, this period presents both a tremendous opportunity and a series of challenges. To succeed in meeting the heightened demand while maintaining quality and efficiency, manufacturers must be prepared in several key areas. Below are some essential considerations for PCBA manufacturers during Black Friday.

One of the most important steps in preparing for Black Friday is ensuring that production schedules are aligned with anticipated demand. Electronics companies often place larger orders in advance to ensure they meet the surge in consumer interest, so PCBAs must be ready in time to ship out. Planning well in advance can help avoid bottlenecks, raw material shortages, or manufacturing delays.

Stock Up on Raw Materials: Early engagement with suppliers is crucial to secure enough electronic components and materials, especially for commonly used parts like capacitors, resistors, and connectors. Shortages in key materials can lead to delays, so having agreements in place with suppliers is critical.

Production Capacity Management: Ensure that production lines are adequately prepared to handle the increased volume. You may need to adjust staffing, increase working hours, or even extend shifts to meet the deadline pressures. Efficient use of production resources will be key to staying on track.

With an increase in production volume, maintaining quality control becomes even more challenging. Black Friday orders tend to be larger, and any defect or error in the assembly process could lead to significant disruptions for both the manufacturer and the client. Therefore, manufacturers need to have rigorous quality control processes in place to ensure all PCBs are up to standard.

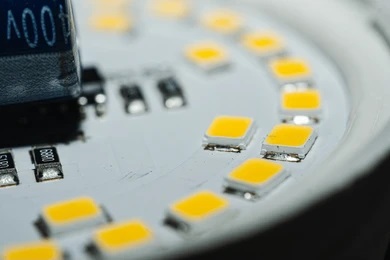

Automated Inspection: Technologies like Automated Optical Inspection (AOI) and X-ray inspection are crucial during periods of high volume. These methods can quickly detect defects in solder joints, component placements, or any other issues without slowing down the production line.

Process Consistency: To avoid errors, maintaining process consistency is key. Standardized procedures for assembly, soldering, and testing will help keep quality in check, even as production volumes increase.

Black Friday can bring unpredictable fluctuations in demand, with some products seeing unexpectedly high orders while others may see less interest. As a PCBA manufacturer, it’s vital to remain agile and flexible in your operations to adapt to these changes.

Scalable Production: You need the ability to scale production up or down as needed. This flexibility might involve adjusting the production process or introducing new shifts or teams to meet sudden spikes in orders.

Efficient Lead Times: Shortening lead times can help meet tight deadlines and make sure products reach customers faster. Effective communication with suppliers and logistics partners can prevent delays in sourcing components or shipping finished products.

Clear communication is essential for managing expectations during Black Friday, especially since many clients will have specific requirements, deadlines, and concerns. As a PCBA manufacturer, it’s vital to establish clear lines of communication with your customers, ensuring they know when to expect delivery and how to address any issues that arise.

Order Confirmation and Deadlines: Ensure that orders are clearly confirmed, with agreed-upon delivery dates. Communication on deadlines should be transparent to avoid misunderstandings. Some clients may need expedited delivery or express production, and understanding these needs upfront will help avoid last-minute pressure.

Proactive Updates: Keep clients informed on the status of their orders. If delays are anticipated, it’s better to inform customers early on so that they can make adjustments or plan accordingly.

Logistics plays a critical role in Black Friday success, as product delivery time is often one of the most significant factors in customer satisfaction. Efficient supply chain management ensures that PCBs are shipped on time and that any unexpected delays are minimized.

Shipping and Inventory Distribution: Consider using multiple distribution centers or warehouses to facilitate quicker deliveries, especially if your clients are spread out across different regions. Shipping from local warehouses can significantly reduce delivery times.

Managing Shipping Partnerships: Coordinate with logistics and shipping partners well in advance to ensure timely dispatch of PCBs. Work closely with shipping companies to guarantee that they have the capacity to handle increased volume, especially around Black Friday and Cyber Monday.

While quality is paramount, competitive pricing during Black Friday can help attract more customers, especially when dealing with high-demand sectors like consumer electronics. Offering cost-effective solutions without sacrificing quality can make your service stand out.

Offer Bulk Discounts: Consider offering bulk order discounts for clients who place larger orders during the Black Friday period. These promotions can help incentivize customers to purchase more and place bigger orders.

Cost Management: Ensure that manufacturing costs are under control to remain competitive while maintaining profitability. Optimizing manufacturing processes, sourcing materials effectively, and improving operational efficiency can help keep production costs down.

Customer service is vital during high-stress periods like Black Friday. With more customers and larger orders, the likelihood of technical issues, questions, or product returns increases. Having an efficient customer support system in place will keep clients happy and reduce the chance of negative feedback.

Technical Support: Providing easily accessible technical support to help clients solve any issues that may arise with the PCBs after delivery will help maintain strong relationships with customers.

Returns and Quality Assurance: Ensure that clear procedures are in place for returns or quality-related issues. Quick and responsive customer support will prevent any small issues from becoming major headaches.

As consumers and businesses alike become more environmentally conscious, offering eco-friendly PCBA solutions can give you a competitive edge. Many customers now prefer working with manufacturers who prioritize sustainability in their production processes.

Green Manufacturing: Adopting green manufacturing practices, such as reducing waste, using recyclable materials, or implementing energy-efficient production techniques, can not only help the environment but also appeal to eco-conscious customers.

Black Friday is an exciting time for PCBA manufacturers, but it requires careful planning and preparation to handle the demand, maintain quality, and deliver excellent customer service. By managing inventory, optimizing production processes, communicating transparently with clients, and maintaining flexible operations, manufacturers can navigate the challenges of this busy season and position themselves for success. With the right strategy, Black Friday can not only boost your business for the short term but also lay the foundation for long-term client relationships and growth.

Simplify Your PCB Journey with XPCB Limited

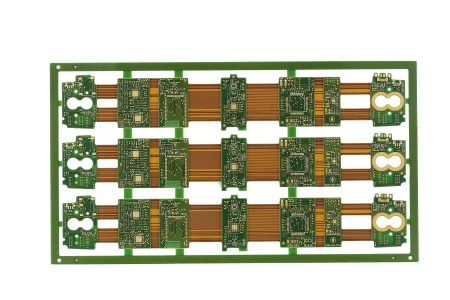

XPCB Limited simplifies the PCB process for you. With our quick-turnaround prototyping and turnkey PCBA services, we ensure that your projects move forward smoothly and efficiently. Trust our commitment to quality and timeliness as we help you bring your designs to life. Choose XPCB Limited for a hassle-free PCB experience.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve