Choosing the right PCB (Printed Circuit Board) manufacturer is critical to ensuring the success of your project, especially when dealing with complex designs. With growing technological demands and intricate PCBA (Printed Circuit Board Assembly) requirements, finding a reliable manufacturing partner is more important than ever. This guide outlines key factors to consider when selecting a professional complex PCB manufacturer to ensure efficient PCBA services.

1. Assess Technical Expertise

The complexity of modern PCBs requires manufacturers to have advanced technical capabilities. Key points to evaluate include:

- HDI Expertise: Look for experience in producing High-Density Interconnect (HDI) boards, which are essential for compact, high-performance devices.

- Via Technologies: Ensure the manufacturer can handle blind vias, buried vias, and microvias, which are common in complex PCB designs.

- Layer Count Capability: Verify the manufacturer’s ability to produce multilayer PCBs, especially for designs requiring 10 or more layers.

- Material Knowledge: They should have expertise with diverse materials like FR4, Rogers, and polyimide to suit various applications.

2. Evaluate Manufacturing Capacity and Quality

A professional PCB manufacturer must have robust production capacity and adhere to high-quality standards. Consider the following:

- Production Scalability: Whether you need prototypes or large-scale production, the manufacturer should accommodate your volume requirements.

- Certifications: Look for industry-standard certifications such as ISO 9001, IPC-A-610, or UL approval to ensure quality and compliance.

- Quality Control Measures: Evaluate their testing processes, including Automated Optical Inspection (AOI), X-ray inspection for vias, and in-circuit testing (ICT).

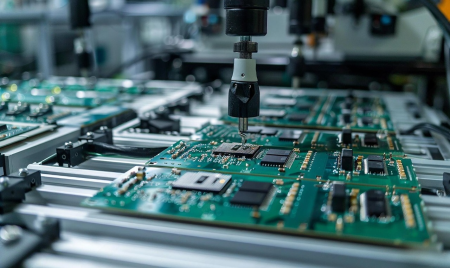

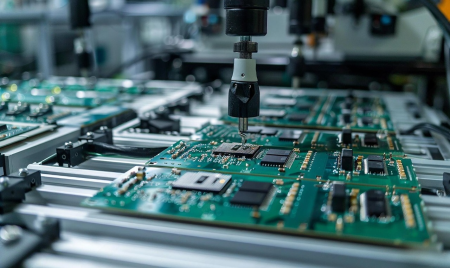

- Equipment and Technology: Advanced manufacturing equipment, such as laser drilling and automated pick-and-place machines, ensures precision and efficiency.

3. Review Turnaround Time and Delivery Efficiency

Time-to-market is crucial in today’s competitive landscape. A reliable PCB manufacturer should provide:

- Quick Prototyping: Short lead times for prototypes to accelerate the design validation process.

- On-Time Delivery: Consistent track record of meeting delivery schedules.

- Global Shipping Options: Capabilities to ship products worldwide with robust logistics support.

4. Consider Design and Engineering Support

Collaboration during the design phase can prevent costly mistakes and streamline production. Look for manufacturers offering:

- Design for Manufacturing (DFM) Analysis: This ensures your design is optimized for manufacturing, reducing errors and production costs.

- Engineering Support: Access to experienced engineers who can assist with troubleshooting and design improvements.

- CAD/CAM Tools: Compatibility with standard design software like Altium, Eagle, or KiCad for seamless file sharing.

5. Examine PCBA Service Integration

Efficient PCBA services go beyond PCB fabrication. A full-service manufacturer should also provide:

- Component Sourcing: Reliable sourcing of quality components from trusted suppliers.

- Assembly Capabilities: Expertise in surface mount technology (SMT), through-hole assembly, and mixed technology.

- Testing and Inspection: Comprehensive PCBA testing, including functional testing, to ensure the assembly meets performance requirements.

- Box Build Services: Value-added services like enclosure assembly and cable harnessing for complete product integration.

6. Analyze Cost and Value

While cost is an important factor, the lowest price does not always mean the best value. Assess the following:

- Transparent Pricing: Look for clear, itemized quotes to avoid hidden fees.

- Cost vs. Quality: Balance affordability with the quality and reliability of the products.

- Long-Term Savings: High-quality PCBs may reduce maintenance and repair costs over the product’s lifespan.

7. Check Customer Reviews and References

Reputation matters when choosing a PCB manufacturer. To gain insights into their reliability:

- Read Reviews: Look for feedback from other clients in your industry.

- Ask for References: Speak with previous customers to understand their experience.

- Case Studies: Request examples of past projects similar to yours.

8. Ensure Compliance with Industry Standards

Different industries have specific requirements for PCBs and PCBA. Make sure the manufacturer complies with standards relevant to your sector, such as:

- Automotive: ISO/TS 16949 compliance for automotive-grade PCBs.

- Medical: ISO 13485 certification for medical device manufacturing.

- Aerospace: AS9100 certification for aerospace-grade PCBs.

- Telecommunications: Expertise in handling high-frequency PCBs for communication systems.

9. Prioritize Communication and Transparency

Effective communication ensures a smooth manufacturing process. Look for a manufacturer that provides:

- Dedicated Support: A single point of contact for project updates and queries.

- Regular Updates: Timely notifications about production status and potential delays.

- Collaboration Tools: Access to project tracking systems for real-time monitoring.

10. Evaluate Sustainability Practices

As environmental concerns grow, consider manufacturers committed to sustainable practices, such as:

- Eco-Friendly Materials: Use of lead-free solder and RoHS-compliant components.

- Waste Management: Recycling programs for production waste.

- Energy Efficiency: Implementation of energy-saving measures in manufacturing processes.

Conclusion

Selecting a professional complex PCB manufacturer for efficient PCBA services requires careful evaluation of their technical expertise, manufacturing capacity, quality standards, and support services. By considering factors like cost-effectiveness, industry compliance, and sustainability practices, you can find a partner that meets your specific needs and ensures the success of your project. Investing time in this selection process will pay off in reliable, high-quality PCBs and assemblies that drive your product’s performance and market success.

Let XPCB Limited be your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.