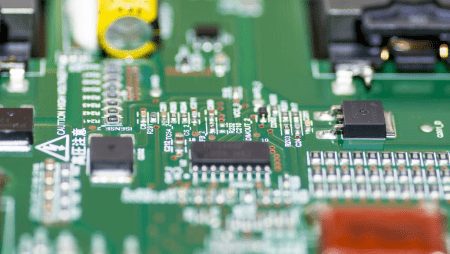

In the fast-paced world of electronics manufacturing, delivering compact, efficient, and high-performance products is a challenge that demands innovative solutions. XPCB Limited rises to this challenge with a proven track record of excellence in High-Density Interconnect (HDI) PCB manufacturing and Surface Mount Technology (SMT) services.

As a trusted industry leader, XPCB combines cutting-edge technology, decades of expertise, and a customer-centric approach to deliver superior quality and precision. Whether you’re creating advanced consumer electronics, medical devices, or telecommunications infrastructure, XPCB has the capabilities to meet and exceed your expectations.

Mastering HDI PCB Manufacturing

High-Density Interconnect (HDI) PCBs are the foundation of modern electronics. Designed to support miniaturization and high-speed applications, HDI PCBs are essential for devices where space is limited, yet performance is non-negotiable.

What Sets HDI PCBs Apart?

- Compact Size:

HDI PCBs utilize microvias, fine lines, and higher layer counts to pack more functionality into smaller spaces.

- Enhanced Electrical Performance:

Reduced parasitic capacitance and inductance make HDI PCBs ideal for high-speed data transmission and low latency applications.

- Improved Thermal Management:

HDI PCBs feature optimized materials and structures to handle heat dissipation effectively, increasing reliability in demanding environments.

- Versatility Across Industries:

From smartphones and wearables to automotive systems and 5G infrastructure, HDI PCBs are used in a wide array of applications.

XPCB’s HDI PCB Manufacturing Capabilities

At XPCB Limited, we specialize in producing HDI PCBs with unmatched precision. Our state-of-the-art facilities are equipped with advanced tools and technologies, including:

- Laser Drilling for Microvias: Achieving via diameters as small as 50 µm, enabling high-density layouts.

- Sequential Lamination: Creating complex, multi-layered HDI PCBs with blind and buried vias for optimal interconnectivity.

- High-Quality Surface Finishes: Options such as ENIG (Electroless Nickel Immersion Gold), immersion silver, and OSP (Organic Solderability Preservatives) for superior solderability and corrosion resistance.

- Impedance Control: Ensuring precise signal transmission for high-frequency applications.

XPCB’s HDI PCBs meet the stringent quality requirements of industries such as aerospace, medical, automotive, and telecommunications, making us a trusted partner for critical projects.

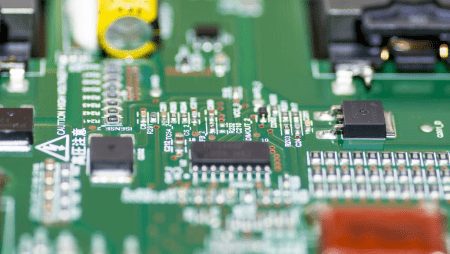

Comprehensive SMT Services: Precision in PCB Assembly

Surface Mount Technology (SMT) is the backbone of modern PCB assembly, enabling the placement of components directly onto the surface of a PCB. This approach is vital for achieving the compact and efficient designs demanded by today’s electronics.

Advantages of SMT Assembly

- Compact Design:

SMT allows for smaller components and higher component densities, reducing the overall size of the PCB.

- Enhanced Performance:

SMT components have shorter lead lengths, resulting in reduced electrical noise and improved high-frequency performance.

- Cost-Effective Production:

Automated assembly processes improve production efficiency and lower costs, even for high-volume projects.

- Versatility:

From resistors and capacitors to microprocessors and LEDs, a wide range of components can be mounted using SMT.

XPCB’s SMT Services

XPCB offers a complete range of SMT assembly services, tailored to meet the unique needs of our clients.

- Advanced Equipment:

Our SMT lines are equipped with high-speed pick-and-place machines, reflow ovens, and AOI (Automated Optical Inspection) systems to ensure precision and quality.

- Capability Highlights:

- Fine-pitch component placement down to 0.2 mm.

- Support for BGA (Ball Grid Array) and QFN (Quad Flat No-lead) packages.

- Double-sided SMT assembly for high-density designs.

- Prototyping and Volume Production:

- Quick-turn prototyping services to accelerate product development cycles.

- Scalable production capabilities to handle low, medium, and high-volume orders.

- Stringent Quality Control:

Every assembly undergoes rigorous testing, including:

- AOI for defect detection.

- X-ray inspection for hidden solder joints.

- Functional testing to verify performance.

Applications of XPCB’s HDI PCBs and SMT Services

- Consumer Electronics:

Our HDI PCBs and SMT assembly services power the latest smartphones, wearables, and smart home devices.

- Automotive Systems:

From ADAS (Advanced Driver-Assistance Systems) to electric vehicle power management, our solutions deliver reliability in critical automotive applications.

- Medical Devices:

Precision-engineered PCBs for diagnostic equipment, imaging systems, and wearable health monitors.

- Telecommunications:

High-speed PCBs and assemblies for 5G infrastructure, networking equipment, and IoT devices.

- Aerospace and Defense:

Robust PCBs designed to withstand extreme conditions in aerospace and military applications.

- Expertise You Can Trust:

With decades of experience in HDI PCB manufacturing and SMT services, XPCB is a name synonymous with quality and reliability.

- State-of-the-Art Facilities:

Our advanced manufacturing plants are equipped with cutting-edge technology to deliver precision and consistency.

- Commitment to Quality:

XPCB adheres to international standards such as ISO 9001, ensuring that every product meets the highest quality benchmarks.

- End-to-End Solutions:

From design support and material selection to manufacturing, assembly, and testing, XPCB provides a seamless, turnkey experience.

- Customer-Centric Approach:

We collaborate closely with clients to understand their unique requirements and deliver customized solutions that align with their goals.

- Sustainability:

XPCB is committed to environmentally friendly practices, utilizing lead-free processes and recyclable materials wherever possible.

The Future of Electronics with XPCB

As the demand for smaller, faster, and more efficient devices continues to grow, the importance of HDI PCBs and SMT services cannot be overstated. At XPCB Limited, we are dedicated to staying at the forefront of innovation, investing in new technologies, and expanding our capabilities to meet the evolving needs of the electronics industry.

Whether you’re developing next-generation consumer electronics, pioneering medical technologies, or building robust systems for aerospace and defense, XPCB is your trusted partner for high-quality PCB manufacturing and assembly.

Contact Us Today

Ready to take your project to the next level? Contact XPCB Limited to discuss your requirements and discover how our expertise in HDI PCB manufacturing and complete SMT services can bring your vision to life.