FPC is also called

Flexible Printed Circuit Board, flexible PCB or Flex PCB. It is a printed circuit board made of flexible copper clad laminate (FCCL) with high reliability and excellent flexibility.

Antenna FPC Board Application

The application of the actual soft board is very common in our lives, almost involving all our electronic products. For example, from the initial DIY installation of hardware driver ribbon leads, digital cameras and camcorders have applications, larger-scale automotive electronics also have soft board applications, and instrumentation, office automation equipment, and medical equipment are also involved.

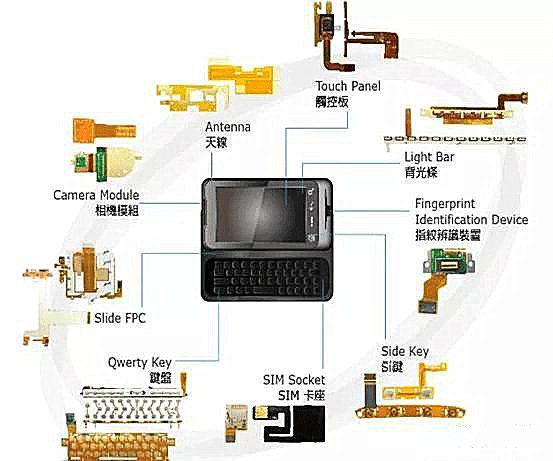

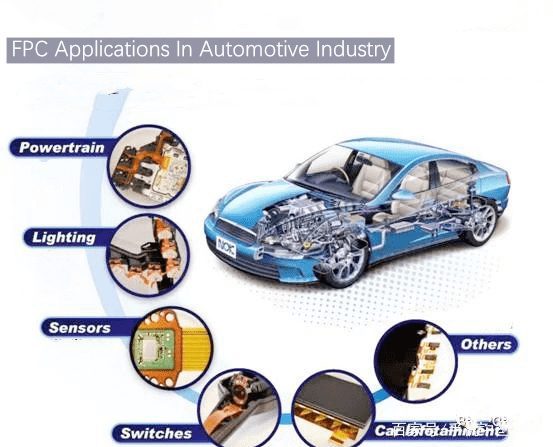

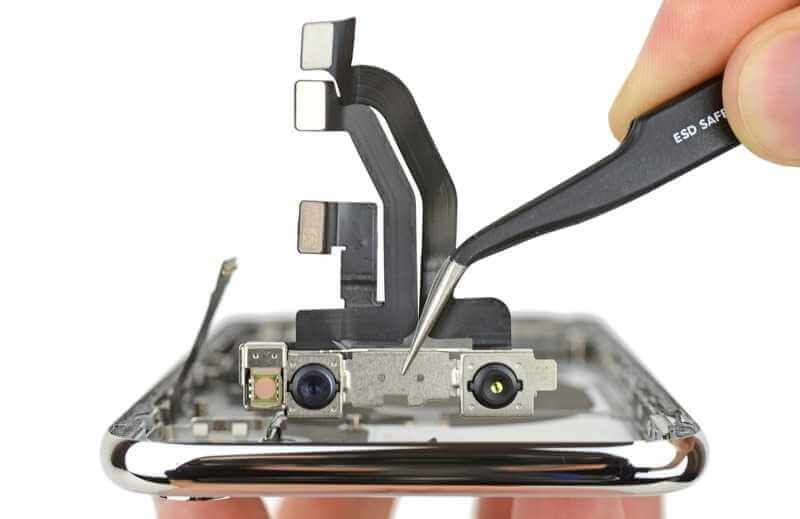

The following is a screenshot of the components that need to be connected to the soft board on mobile phones, notebooks, and automobiles.

FPC Application on Smartphone

FPC Application on laptop

FPC Application in Car

It can be seen that the application range of FPC is very wide, and the demand market is also very large. Statistics show that China’s FPC market will reach more than 30 billion yuan. With the development of miniaturized terminals such as mobile phones, tablets, notebook computers, and wearables, and consumers’ next innovations in product form, such as the adoption of full-screen and flexible screens, the demand for FPCs will only increase.

LCP FPC Pushes Flex PCB Industry Innovation

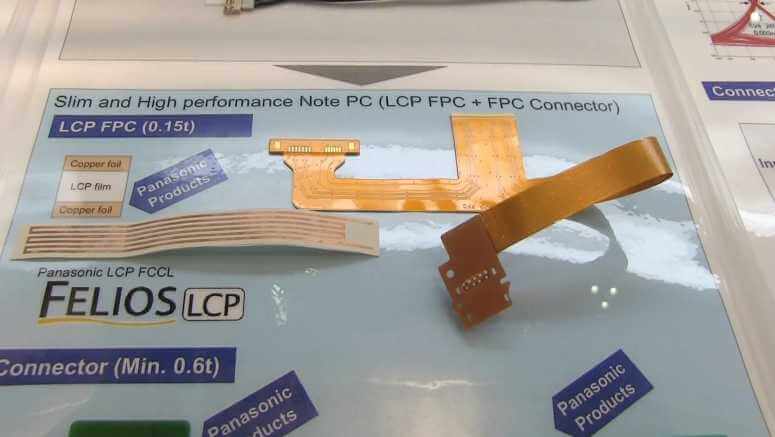

FPC, or the soft board market, has experienced years of development. The traditional PI soft board has gradually shown its application disadvantages, especially in high-frequency transmission. The limitations and disadvantages of old materials have also promoted the development of new materials and new processes in this field, and the soft boards of the LCP process have gradually entered the public’s field of vision.

LCP is a new type of thermoplastic organic material, which can ensure high-frequency and high-speed transmission under the premise of high reliability. LCP has good electrical characteristics: it can almost maintain a constant dielectric constant in the entire radio frequency range up to 110 GHz, with good consistency; secondly, the tangent loss is very small, only 0.002, and it only increases to 0.0045 even at 110 GHz. Suitable for millimeter wave applications; again, the thermal expansion characteristics are very small, and can be used as an ideal high-frequency packaging material.

These electrical characteristics can enable LCP soft boards to be applied to terminal antennas in the 4G and 5G era, and to cope with the gradual shift of wireless transmission to high-frequency and high-speed directions, especially in millimeter wave applications.

LCP FPC Becomes 5G Mainstream Antenna Technology

The application range of the soft board is very wide, but through the new material technology, it will help the development of the terminal antenna, especially in the coming 5G network.

Take the mobile phone as an example. Everyone may care about the screen, processor, memory and other components of the mobile phone, but rarely pay attention to the antenna. The antenna at the front end of the radio frequency is relatively far away from the user and is at the bottom of the communication technology, so everyone’s daily focus is not on this, but it is critical to the role of smart phone wireless terminals.

Under the trend of 5G and the Internet of Things, front-end RF and antennas have begun to gain attention. The antenna, as its name implies, is responsible for the first radio frequency signal. It determines communication indicators such as communication quality, signal power, signal bandwidth, and connection speed.

Returning to our mobile phone applications, smart phones include Cellular (LTE/ TD-SCDMA/ FD-SCDMA/ WCDMA/ CDMA2000/ GSM, etc.), BT, Wi-Fi, GPS, NFC and many other RF front-end functional modules, these different modes The communication method enables us to realize a series of applications such as text, voice, video communication, Internet access, web browsing, map positioning, and file transmission. We need wireless connection, and the connection needs to rely on the antenna for signal transmission and reception.

Wireless terminal devices such as mobile phones need to deal with different environmental conditions, and soft boards have become the mainstream material technology for antennas. Antennas can be divided into network coverage antennas and terminal antennas. The former is a base station antenna. We will not expand it. We mainly talk about our commonly used mobile phone and other wireless terminal antennas, including mobile phone antennas, mobile TV antennas, laptop wires, GPS antennas, etc.

For smart phones, due to industry and market development, with the integration and high integration of mobile phone appearance design, the internal space is continuously reduced, which can be said to be extremely difficult for antenna design. Mobile phone antennas have evolved from the early external antennas to built-in antennas. At the same time, the soft board has become the mainstream technology, exceeding 70%.

With the gradual stepping into the 5G era, communication frequencies will also fully enter the high-frequency field, and high-speed and large-capacity will become the main tune. According to the 5G development roadmap, the first stage is the application below 6GHz, and after 2020, the second stage is the application of millimeter wave (30-60GHz).

The signal frequency of terminal antennas such as smart phones is constantly increasing, high-frequency applications are increasing, and the demand for high-speed network connections is also increasing. As the antenna and transmission medium in the terminal equipment, the soft board is inevitable to upgrade its technology.

Traditional Flex PCBs Drops While LCP FPC Rises

The traditional flexible board is composed of a multi-layer structure composed of copper foil, insulating base material, cover layer, etc., using copper foil as the conductor circuit material, PI film as the circuit insulating base material, PI film and epoxy resin adhesive as protection and isolation The cover layer of the circuit is processed into a PI soft board through a certain process.

At present, the most widely used soft board substrate is mainly polyimide (PI), but due to the large dielectric constant and loss factor of the PI substrate, high moisture absorption, and poor reliability, the PI soft board The high frequency transmission loss is serious and the structural characteristics are poor, and it has been unable to adapt to the current high frequency and high speed trend.

As mentioned earlier, LCP (liquid crystal polymer) is a new type of thermoplastic organic material that can achieve high frequency and high speed under the premise of high reliability.

It has the following electrical characteristics: (1) Almost constant dielectric constant can be maintained in the entire radio frequency range up to 110 GHz, with good consistency; (2) Tangent loss is very small, only 0.002, even at 110 GHz, it only increases to 0.0045, very suitable for millimeter wave applications; (3) The thermal expansion characteristic is very small, and it can be used as an ideal high-frequency packaging material.

At present, LCP is mainly used in high-frequency circuit substrates, COF substrates, IC packaging and other fields. It is foreseeable that as the trend of high-frequency and high-speed applications becomes more and more obvious, the new process of LCP will replace PI and become a new soft board process.

LCP can achieve higher miniaturization

Take mobile phones as an example. With the rise of full screens, product morphology changes, more components added, larger batteries, etc., these are all reasons for further compression of the internal space of mobile phones. The space where antennas can be used for design is getting smaller and smaller, and miniaturization methods such as antenna arrays are emerging one after another.

There are three main aspects to the compression of the internal space of the mobile phone: (1) Full-screen design, although the length and width of the mobile phone become larger, the thickness continues to decrease. (2) More and more functional components integrated by smart phones, such as sensors and cameras, further squeeze space. (3) The power consumption of larger screen sizes and more functional components has increased dramatically, while the battery density usually only increases by 10% per year. The increased power demand makes the battery volume larger and larger.

In order to change the “living space” of the antenna inside the mobile phone, in addition to optimizing the antenna performance and adopting the array structure, more efforts need to be made from the essential form of the antenna.

The LCP soft board has better flexibility and can further improve the space utilization compared with the PI soft board. Use resistance change greater than 10% to judge. Under the same experimental conditions, LCP soft board can withstand more bending times and smaller bending radius than traditional PI soft board, so LCP soft board has better Flexible performance and product reliability.

In addition, the excellent flexibility allows the LCP soft board to freely design the shape, so as to fully adapt to the small space inside the mobile phone. Take the flexible flexible board that spans the battery as an example. The LCP flexible board can fit the battery well, while the PI flexible board cannot close to the battery surface under the influence of the rebound effect, which causes the internal structure of the whole machine to be loose and wasteful. A certain amount of space.

The LCP soft board can reduce the thickness of the antenna transmission line by 65%, which can further improve the space utilization. The traditional design uses an antenna transmission line, which is what we call a coaxial cable, to transmit the signal from the antenna to the motherboard, while multi-mode and multi-frequency require multiple antenna transmission lines to be placed in a small space.

The LCP soft board has the same excellent transmission loss as the antenna transmission line. It can carry several transmission lines in a three-layer structure of only 0.2 mm and lead out multiple radio frequency lines. This means that the use of the LCP soft board can replace the thick Antenna transmission line and coaxial connector reduce the thickness.