- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

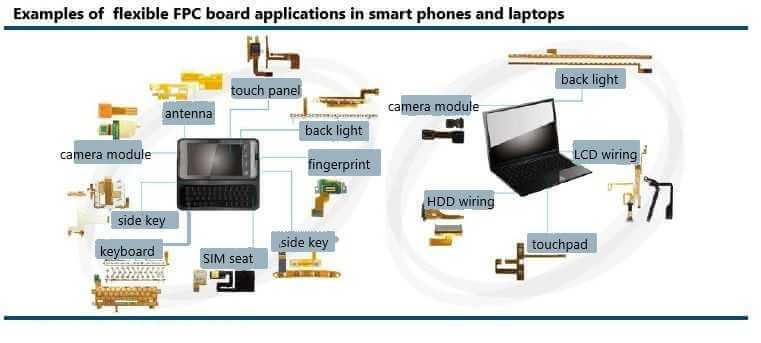

The advent of 5G era also creates a huge demand market for FPC industry, which will be brought into a new round of growth. With its high density, light weight and thin thickness, FPC can significantly reduce the size of hardware and is now widely used in both smartphones and computers.

There are rumors that Huawei will launch a TV product. Yu Chengdong, CEO of Huawei’s consumer business, responded: Huawei does not make traditional home appliances, nor will it make traditional TVS. Industry insiders Wangxiao speculate that the “unconventional TV” is likely to use Huawei’s own chips to make a breakthrough in 5G functions.

As one of the choices of 5G equipment, FPC industry will undoubtedly usher in unprecedented development opportunities.

FPC is located in the middle and upper reaches of the electronic industry chain. The upper reaches of the industry chain include FCCL manufacturers and raw material suppliers such as PU/PET film and rolled copper foil. The middle reaches are FPC manufacturers and the downstream is terminal applications.

At present, the global FCCL is mainly supplied by Japan, South Korea, China and Taiwan, and the trend of stronger is becoming stronger. The previously chaotic FPC market begins to enter the shuffling stage, and the living environment of small and medium-sized manufacturers tends to deteriorate.

FPC manufacturing industry emerged in the 1960s, and the United States and other countries with advanced electronic technology first applied FPC. In the early 21st century, the rapid development of consumer electronics market has promoted the rapid development of FPC industry, which is also applied in high-end electronic products such as aerospace and military applications. Later, with the continuous increase of production costs in Europe and The United States, the focus of FPC production underwent two shifts and gradually shifted to Asia.

After the shift of focus of FPC production, the number of FPC layouts in Japan, South Korea and China surged. According to IHS, the potential sales activity created by 5G will reach $12.3 trillion globally by 2035.

Smartphone is one of the key scenarios of 5G, and 5G driver undoubtedly brings opportunities for the development and innovation of smartphone antenna.

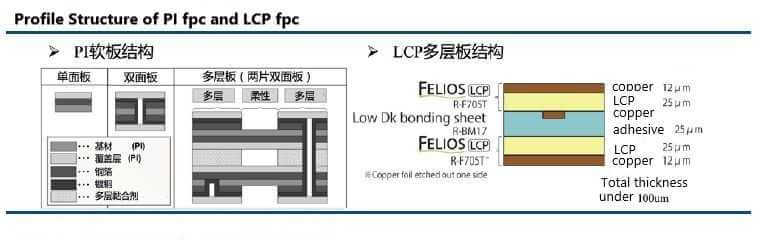

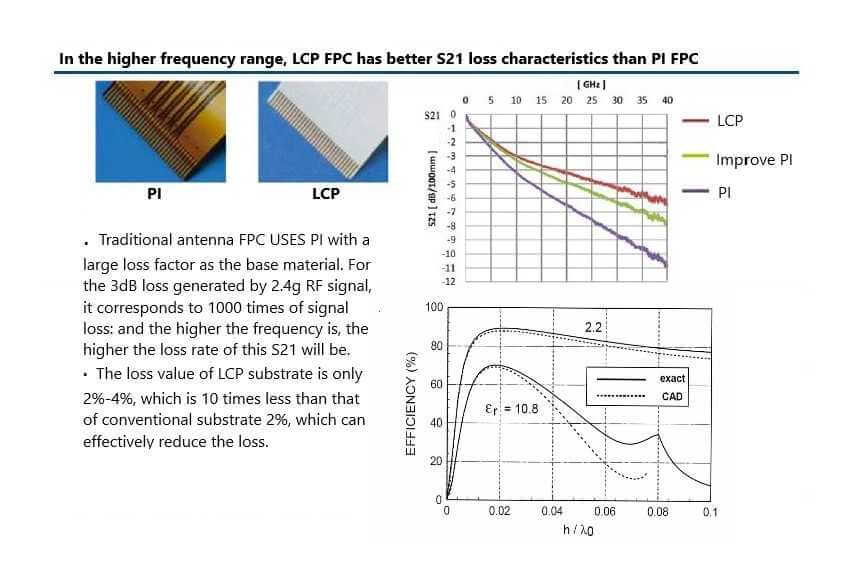

According to the insiders, at present, the technology of felxible printed circuit antenna occupies the mainstream position of antenna technology with a market share of 70%. Under the high speed and high frequency transmission trend brought by 5G, the traditional antenna flex PCB encounters performance bottleneck. With less loss of meson and conductor, flexibility, tightness and other characteristics, LCP (liquid crystal polymer) successfully ascended, replacing traditional PI (polyimide) and other FPCB as one of the new technologies.

Especially since Apple Introduced the multi-layer LCP antenna, a “weathervane” of mobile phone materials and technology, into Apple X for the first time, some people in the industry interpreted this move as Apple’s advance layout and material verification for 5G wireless transmission. According to relevant data, the penetration rate of LCP in the smartphone market is expected to reach 25% by 2021, the market size is expected to exceed 4.3 billion US dollars, and the CAGR will reach 44.82% by 2021.

There are opinions in the industry that LCP represents the direction of mobile phone antenna in the future 5G era. Is LCP really so popular in 5G era?

Could the LCP become mainstream?

LCP material is a new thermoplastic organic material with advantages of low transmission loss, bendability, strong dimensional stability, strong moisture absorption, etc. When applied to 5G mobile phone antenna, the loss value of LCP substrate is only two-thousandth to four-thousandth, which is ten times smaller than the traditional substrate.

Iphone X’s antenna process action, it seems that the industry has seen the LCP in the 5G mobile phone antenna market explosion spring breeze. There are three main reasons for iphone X’s adoption of multi-layer LCP.

Firstly, in the future, mobile phones will develop towards 5G, and LCP material medium loss and conductor loss will be less.

Secondly, the iPhoneX has a full screen, leaving less headroom for the antenna. The antenna design needs to be changed, while the LCP antenna can save space.

Thirdly, the LCP antenna can replace the RF coaxial connector.

Domestic China PCB upstream and downstream manufacturers have expressed their optimism with action. LCP FPC has a similar technological process to traditional PI soft plate. Its industrial chain is divided into upstream raw material manufacturers, FCCL suppliers, mid-stream soft plate manufacturers, and downstream module manufacturers.

Li Yan, an expert, said publicly that with the advent of 5G era and the rapid penetration of comprehensive screens, the demand for LCP soft plate antennas will further increase. Meanwhile, compared with the former PI substrate with a value of less than $1, the value of the upper and lower LCP antennas will be around $10. Industry analysts believe that in the future, LCP antenna may become the mainstream antenna of smartphones in the 5G era.

For the market speculation hot LCP, there are experts hold a different attitude.

“The application of LCP materials in 5G mobile phone antennas may be a flash in the pan and a short-term choice.” Zhou Hongwei, chairman of Shenzhen Weihang Magnetoelectric Technology Co., LTD., said to New Materials online ®.

The end of December 2018, famous apple analyst Guo Ming , said apple was first adopted in iPhoneX multilayer Liquid Crystal Polymer antenna, but will the new iPhone in 2019 using Modified PI, namely the MPI antenna is the same as the LCP antenna performance of high frequency band

Zhou Hongwei expressed Apple’s idea of reelecting MPI, citing that China’s core frequency band in the early stage of 5G is 2.6GHz-4.9ghz, and PI antenna material can be applied after improvement. “There are new modification techniques coming out all the time, not necessarily with LCP.” According to Zhou, MPI’s performance in the 10-15ghz hf signal is no different from that of the LCP antenna due to the improved fluoride formulation.

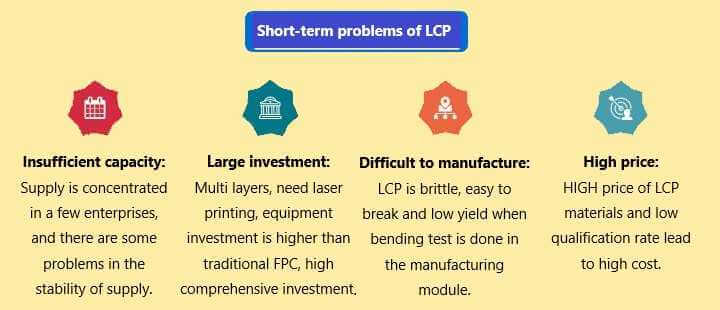

The disadvantages of LCP are low yield rate, low downstream bargaining power and few suppliers. According to industry insiders, the molecular structure of LCP is hard, which makes it more difficult for LCP materials to be made into thin films. At present, only a few suppliers of soft copper foil substrate have this technical capability in the market, and the material price remains high. In addition, LCP raw materials mainly come from Japan’s Murata, Sumitomo and other giants, and domestic raw material manufacturers are few.

The LCP as an antenna is only a transitional material, and the current LCP has too high a dielectric coefficient in the millimeter band, which is a hard hit. “In the millimeter-wave era, future antennas will use ‘double low materials,’ ceramic or plastic materials with low dielectric coefficient and low dielectric loss.”Zhou hongwei said.

Whatever, in spite of this, many institutions or enterprises have been studying and using LCP materials.Because even though it’s expensive, the cost of a good product is negligible.

If you want to know more about LCP materials, please click on the link for more details

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve