- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

PCB means printed circuit Board, or Rigid Board for short. FPCB refers to flexible circuit board, also known as flex circuit board, referred to as FPC.

Miniaturization is the inevitable development trend of electronic products, quite a number of consumer products, SMT, because the assembly space, the relationship between the SMD on FPC is pasted on the complete machine assembly, FPC on a calculator, mobile phones, digital cameras, digital cameras and other digital products widely applied, SMD SMT in FPC has become one of SMT technology development trend. FPC surface SMT process requirements and traditional PCB SMT solutions have many differences, to do a good job of FPC SMT process, the most important thing is positioning. Because the HARDNESS of FPC board is not enough, it is soft, if the special plate is not used, it cannot be fixed and transferred, and also cannot complete the printing, SMT, through the furnace and other basic SMT processes.

The following are the key points of FPC pretreatment, fixation, printing, SMT, reflow welding, testing, inspection, splicing and other procedures in THE production of FPC SMT

FPC board is relatively soft, factory is generally not vacuum packaging, easy to absorb the moisture in the air in the process of transportation and storage, need to be pre-baked before SMT line, the water will be slowly forced out. Otherwise, under the high temperature impact of reflow welding, the water absorbed by FPC will be quickly gasified into water vapor, which will easily lead to FPC stratification, foaming and other defects.

The pre-baking condition is generally the temperature 80-100℃C time 4-8 hours. In special cases, the temperature can be raised to more than 125℃C, but the baking time should be shortened accordingly.

Before baking, be sure to do a sample test to determine if the FPC can withstand the set baking temperature, or consult the FPC manufacturer for appropriate baking conditions.

When baking, FPC stacks should not be too large, 102OPNL is suitable. Some FPC manufacturers will place a piece of paper between each PNL for isolation. It is necessary to confirm whether the paper used for isolation can withstand the set baking temperature. FPC after baking should be free from obvious discoloration, deformation, warping and other defects, which can only be put into line after IPQC sampling inspection is qualified.

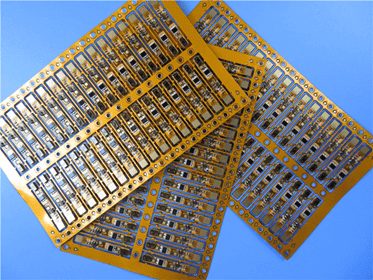

According to the CAD file of the circuit board, the hole positioning data of FPC is read to manufacture the high-precision FPC positioning template and special carrier, so that the diameter of the positioning pin on the positioning template matches the positioning hole on the plate and the diameter of the positioning hole on the FPC.

Many FPC are not of the same thickness due to the protection of part of the lines or design reasons. Some places are thick while others are thin, and some are reinforced with metal plates. Therefore, the joint between the loading plate and FPC needs to be processed, polished and dug according to the actual situation to ensure that FPC is flat during printing and mounting.

The material of the carrier plate requires light weight, high strength, little heat absorption, fast heat dissipation, and small warping deformation after many thermal shocks.

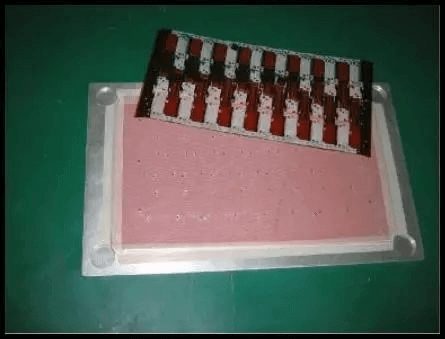

Commonly used plate materials are synthetic stone, aluminum plate, silicone plate, special high temperature resistance magnetized steel plate.

Ordinary plate design is convenient and proofing is quick. The commonly used common carrying plate materials are engineering plastics (synthetic stone), aluminum plate, etc., engineering plastic carrying plate life is 3,000-7,000 times, easy to operate, good stability, not easy to absorb heat, not hot, the price is more than 5 times of aluminum plate.

Fast absorption and heat dissipation, no temperature difference between inside and outside, simple repair deformation, cheap price, long life, the main disadvantage is hot, to use heat insulation gloves to take.

The material is self-adhesive, FPC is directly stuck to it without tape, and it is easy to remove, no residual glue, and it is high temperature resistant. In the use of silica gel plate, the use of chemical process, silica gel material in the use of the process of aging viscosity will decline, during the use of the viscosity will also decline when not clean, short life, at most 1000-2000 times, the price is also relatively high.

Here we will take the ordinary plate as an example to detail the SMT points of FPC. When using the silica gel plate or magnetic fixture, FPC fixation should be much more convenient, without the use of tape, but the process points of printing, patch, welding and other procedures are the same.

Before proceeding with SMT, the FPC needs to be precisely fixed to the board. In particular, it is important to note that the time between printing, mounting and welding is as short as possible after the FPC is fixed on the board.

There are two kinds of carrier plate, locating pin and locating pin.

Loading board without positioning pin, and should take the positioning pin, the positioning of the template to load board on the set of the dowel pin in the template, make the dowel locating hole on the load board, FPC piece of a set in revealing the dowel pin, reoccupy adhesive plaster, and then let the load board isolation, FPC positioning template for printing, SMT and soldering.

There are several spring locating pins with a length of about 1.5mm fixed on the plate with locating pins. FPC- sheets can be directly placed on the spring locating pins of the plate and then fixed with adhesive tape.

In the printing process, the spring locating pin can be completely pressed into the plate by the steel mesh without affecting the printing effect.

FPC of solder paste composition is no special requirements, the size of the tin ball particles and metal content will be subject to have FPC on fine pitch IC, but FPC high performance requirements of the solder paste printing, solder paste should be has good thixotropy, solder paste should be able to easily print demoulding and can firmly adhere to the surface of FPC, there will be no mold release bad block stencil hole leakage or produce the bad such as collapse after printing.

Because FPC is loaded on the board and has high temperature resistant tape for positioning, the plane of FPC is inconsistent, so the printing surface of FPC is unlikely to be as flat as PCB and consistent in thickness and hardness, so metal scraper should not be used, but polyurethane scraper with hardness of 80-90 degrees should be used.

Solder paste printing machine should be equipped with optical positioning system, otherwise it will have a great impact on the printing quality. Although FPC is fixed on the board, there will always be some small gap between FPC and the board, which is the biggest difference from PCB hard board, so the setting of equipment parameters will also have a great impact on the printing effect.

The printing station is also the key station to prevent FPC smudges. It is necessary to wear finger covers, keep the station clean, wipe the steel mesh frequently, and prevent solder paste from contaminating FPC gold fingers and gold-plated keys.

According to the characteristics of the product, the number of components and the placement efficiency, the medium and high-speed placement machine can be used for the placement.

Since each FPC has an optical MARK for positioning, SMD mounting on FPC is not very different from mounting on PCB.

It should be noted that although FPC is fixed on the board, its surface cannot be as flat as PCB hard board, and there must be a local gap between FPC and the board. Therefore, the suction nozzle drop height and blowing pressure should be precisely set, and the suction nozzle movement speed should be reduced.

At the same time, FPC is dominated by coupling boards, and the yield of FPC is relatively low. Therefore, it is normal for the whole PNL to contain some defective PCS, which requires the SMT machine to have the BAD MARK recognition function. Otherwise, the production efficiency will be greatly reduced in the case that such non-integral PNL is all good boards.

Mandatory hot air convection infrared reflow furnace should be used, so that the temperature on FPC can be more uniform change, reduce the occurrence of bad welding.

If single-sided tape is used, it can only fix the four sides of FPC, and the middle part is deformed under hot air, so the welding plate is easy to be inclined, and the molten tin (liquid tin at high temperature) will flow, resulting in air welding, continuous welding and tin ball, making the process defective rate higher.

Due to the different heat absorption of the carrier plate and the different types of components on FPC, the temperature rises rate and the heat absorption rate are different after they are heated during the reflow welding process. Therefore, carefully setting the temperature curve of the reflow welding furnace has great influence on the welding quality.

The more reliable method is to put two boards with FPC at the front and back of the test board according to the actual plate spacing during production. Meanwhile, components are attached to the FPC of the test board, and the test temperature probe is welded to the test point with high-temperature solder wire, and the probe wire is fixed on the board with high-temperature resistant tape.

Note that the high temperature resistant tape does not cover the test point. The test points should be near the solder joints and QFP pins on each side of the plate, so that the test results can better reflect the real situation.

In the furnace temperature debugging, because the average temperature of FPC is not good, so it is better to use temperature rise/heat preservation/reflux temperature curve mode, so that the parameters of each temperature area is easy to control some, in addition, FPC and components are less affected by thermal shock.

According to experience, it is better to adjust the furnace temperature to the lower limit of the solder paste technical requirements, the furnace can generally use the minimum wind speed of the furnace, the chain stability of the furnace is good, there is no jitter.

Because the plate absorbs heat in the furnace, especially the aluminum plate, the temperature is higher when it comes out of the furnace, so it is better to add a forced cooling fan in the furnace to help cool down quickly.

At the same time, operators should wear heat insulation gloves to avoid being burned by the high temperature carrier.

When taking the FPC from the carrier plate for completion of welding, the force should be uniform and no brute force should be used to avoid tearing or creasing the FPC.

The FPC removed was placed under a magnifying glass of more than 5 times for visual inspection, focusing on the inspection of surface residue, discoloration, tin-stained goldfinger, tin-bead, IC pin hollow welding, welding and other problems.

FPC is generally not suitable for AOI inspection, because the surface of FPC cannot be very smooth, resulting in a high misjudgment rate of AOI. However, with the help of special test fixture, FPC can complete the test of ICT and FCT.

Since FPC is mostly linked to the board, it may be necessary to make the board before the test of ICT and FCT. Although blade, scissors and other tools can also be used to complete the board operation, the operation efficiency and quality are low, and the scrap rate is high.

If it is the mass production of special-shaped FPC, it is suggested to make special FPC stamping die for stamping segmentation, which can greatly improve the working efficiency. Meanwhile, the edge of blanking FPC is neat and beautiful, and the internal stress generated during stamping and cutting is very low, which can effectively avoid solder cracks.

For SMD mounting on FPC, the precise positioning and fixation of FPC is the key point, and the key to the fixation is to make the appropriate plate.

FPC is followed by pre – baking, printing, SMT and reflow welding.

FPC SMT process obviously is higher than the PCB board and a lot of difficulty, so it is necessary to accurately set the process parameters, and at the same time, strict production process control are also important, must ensure that operators strictly implement SOP on each article, with line engineers and IPQC inspection should be strengthened, timely discover the unusual situation of production line, analyze the reason and take the necessary measures to the defective rate of FPCSMT line control within dozens of PPM.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve