- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

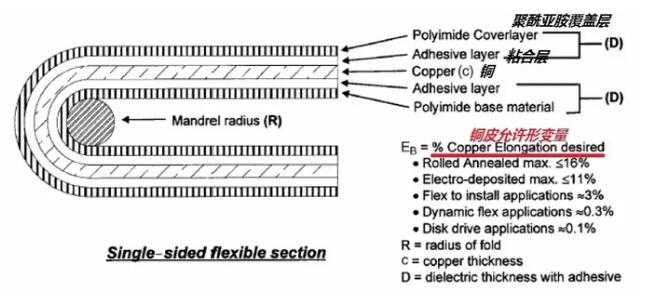

When the FPC flexible circuit board is bent, the type of stress on both sides of its center line is different. The inside of the curved surface is pressure, and the outside is tension. The magnitude of the stress is related to the thickness and bending radius of the FPC flexible circuit board. Excessive stress will cause delamination of FPC flexible circuit boards, copper foil breakage, and so on. Therefore, the laminate structure of the FPC flexible circuit board should be reasonably arranged during the design, so that the two ends of the center line of the curved surface are laminated as symmetrically as possible. At the same time, the minimum bending radius must be calculated according to different applications.

Its minimum bending radius can be calculated by the following formula: R=(c/2)[(100-Eb)/Eb]-D where: R=minimum bending radius (unit µm), c= copper thickness (unit µm) , D = cover film thickness (unit µm), EB = allowable deformation of copper skin (measured in percentage) Different types of copper have different deformations of copper skin.

A, the maximum deformation of the copper skin of crushed copper is ≤16%

B, the maximum deformation of the copper skin of electrolytic copper is ≤11%.

And in different use occasions, the value of the deformation of the copper skin of the same material is different. For the occasion of one-time bending, the limit value of the critical state of fracture is used (for rolled copper, the value is 16%). For bending installation design, use the minimum deformation value specified by IPC-MF-150 (for rolled copper, the value is 10%). For dynamic flexible applications, 0.3% of the copper deformation is used. For magnetic head applications, 0.1% of copper deformation is used. By setting the allowable deformation of the copper skin, the minimum radius of bending can be calculated.

Dynamic flexibility: This kind of copper skin application scene is realized by deformation. For example, the phosphor copper shrapnel in the IC card socket is the part that contacts the chip after the IC card is inserted. The shrapnel is constantly deformed during the insertion process. This application scenario is flexible and dynamic.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve