- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

I often hear people talk about solder mask opening in PCB design. What is windowing, PCB design windowing what to use, how to open a solder mask? The following is your answer.

What is solder mask opening?

Usually, the leads on the PCB are covered with oil to prevent short circuits and damage to the equipment. The solder mask opening is to remove the coating layer from the wire so that it can be exposed to tin.

What is the use of solder mask opening in PCB design?

PCB design can not only realize the PCB as a plug and play plug-in, but also increase the thickness of solder to achieve the purpose of excessive current.

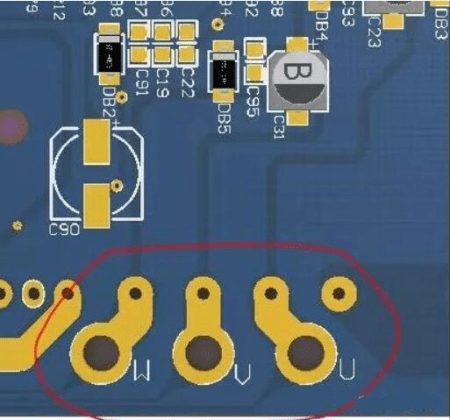

As shown in the figure above, the solder mask opening.

PCB solder mask openings are not uncommon, and one of the most common is likely to be memory chips. Anyone who has taken apart a computer knows that there is a golden finger on the memory strip. In this case, the golden finger is the open solder mask, plug, and play. The solder mask opening also has a very common function, that is, the late iron increases the thickness of the copper foil, which facilitates the excessive current, which is more common on the power board and the motor control board.

How to open solder mask in PCB design?

In PCB design, you can set up threading and solder mask opening on the TOP/BOTTOM SOLDER layer. Top /BOTTOM SOLDER green oil layer: the TOP/BOTTOM SOLDER green oil layer is laid to prevent tin from the copper foil and maintain insulation.

The solder mask green oil can be set at the welding pad, through-hole, and non-electrical wiring of this layer.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve