- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In PCB design, we are always looking for new technical improvements to simplify our work and achieve more as designs get smaller and denser. One of these improvements is the microvia. These laser-drilled through holes are smaller than conventional through holes and have different aspect ratios. Because of their small size, they simplify the task of wiring trajectories, allowing us to pack more wiring into a narrower space. Here’s more information about microvia aspect ratios and how using microvia can help you with your PCB design.

First, let’s look at some basic information about through holes and their use on printed circuit boards. A through-hole is a hole drilled in a PCB. Electroplating holes carry electrical signals from one layer to another. Just as cabling transmits signals horizontally in a PCB, through holes can also transmit these signals vertically. The size of the through-holes can vary from small to large, with larger through-holes used for power supply and grounding mesh, and even for connecting mechanical features to the board. Standard through-holes are created by mechanical drilling. They can be divided into three categories:

Through-hole: A hole drilled from the top to the bottom into the PCB.

Blind hole: A hole drilled from the outside to the inside of a circuit board without going all the way through the board like a through hole.

Buried hole: The hole that begins and ends only in the inner layer of the plate. These holes do not extend to any outer layer.

Microthrough-holes, on the other hand, differ from standard through-holes in that they are drilled with a laser, which makes them smaller than conventional holes. Depending on the width of the board, mechanical holes are usually no less than 0.006 in. (0.15 mm), from which the microvias begin to shrink. Microvias are also different in that they usually span only two layers, as plating copper into these holes can be difficult for manufacturers. If more than two layers of direct connection are required, the pores can be stacked on top of each other.

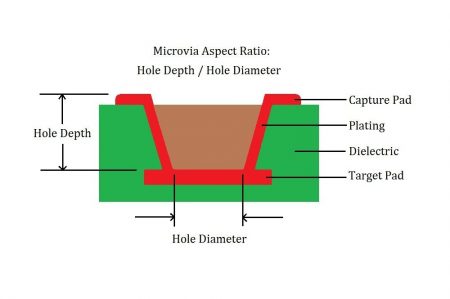

microvias starting from the surface layer do not need to be filled, but the buried microvias will be filled with different materials depending on the application. Stacked microvias are usually filled with electroplated copper to enable the connection between the stacked through holes. Another way to connect microvias through a stack of layers is to interlace them and connect them with short wires. As shown in the figure below, the profile of the microhole is different from that of the conventional through hole, resulting in a different aspect ratio.

The aspect ratio of a through-hole is the ratio of the depth of the hole to the diameter of the hole (hole depth to hole diameter). For example, a standard circuit board that is 0.062 “thick and has 0.020” through holes should have an aspect ratio of 3:1. This ratio serves as a guide to ensure that manufacturers do not exceed their capabilities. The equipment they were drilling. For standard boreholes, the aspect ratio should normally not exceed 10:1, which will allow a 0.062-inch board to drill 0.006 inch (0.15 mm) through it.

When using microholes, the aspect ratio varies greatly depending on their size and depth. Electroplating smaller holes can be difficult, and trying to electroplate a single hole on 10 layers of a board causes many problems for PCB manufacturers. However, if the holes span only two of these layers, plating becomes much easier. The IPC used to define microvias based on their size, which was 0.006 in. (0.15 mm) or less. Over time, this size became so common that IPC decided to change its definition to avoid constantly updating its specifications as technology changed. Today, IPC defines a microhole as a hole with an aspect ratio of 1:1, as long as the hole is no deeper than 0.010 inch or 0.25 mm.

In PCB design is to get more routing in a smaller area as the density of PCB technology increases. This led to the use of blind and buried through holes, as well as the method of embedding through holes in surface-mounted pads. However, because of the additional drilling steps involved, blind and buried through holes are more difficult to manufacture, and drilling can leave material in the hole, leading to manufacturing defects. Conventional through-holes are also often too large to fit into the smaller surface-mount pads found in today’s high-density devices. However, microvias can help solve all of these problems:

MICROVIA makes it easier to manufacture small blind and buried holes.

The micro-through-holes will be suitable for smaller surface-mounted pads, making them particularly suitable for high-pin count devices such as ball-grid arrays (BGA).

Due to its small size, the microvias will allow more wiring to be done around them.

Due to their size, microvias can also help reduce EMI and improve other signal integrity issues.

Microvias are an advanced method of PCB manufacturing, and if your board does not need them, you will obviously want to use standard holes to reduce costs. However, if your design is dense and requires extra space, check to see if using microvias can help. As always, it is a good idea to check performance with the contract manufacturer before designing a PCB with microholes.

Once you have established contact with the manufacturer, the next step is to configure your PCB design tools to use microholes. To effectively use the details of a microhole design, you need to do a lot of things in the tool. This will include new through-hole shapes and consequent design rules. Microvias can be stacked up, which is often not available with regular through-holes, so your tool must be able to handle this as well.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve