- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

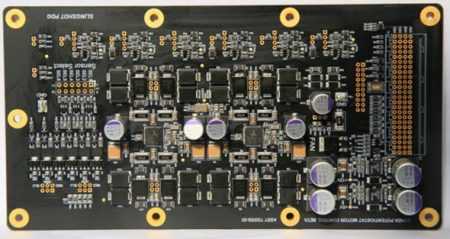

SMT is surface assembly technology, which is currently the most popular technology and placement process in the electronic assembly industry. So, what are the SMT chip processing solutions?

I. SMT SMD Processing Characteristics

1, high assembly density, small size of electronic products, light weight, SMD processing components of the volume and weight of only about 1/10 of the traditional cartridge components.

2, high reliability, high vibration resistance, low defect rate of solder joints.

3, good high frequency characteristics, reducing electromagnetic and radio frequency interference.

4、Easy to realize automation and improve production efficiency.

5、Reduce cost up to 30%~50%, save material, energy, equipment, manpower, time, etc.

II. SMT Circuit Board Mounting Solutions

SMT processing methods and processes are completely different from the installation methods and processes of through-hole inserts. At present, in the application of SMT technology in electronic products, there are some are all SMT components of the circuit board; but there is the so-called “mixed process”, that is, in the same circuit board, both cartridge THT components, but also surface-mounted SMT components.

Three kinds of SMT chip processing solutions

1. All using surface mount

Printed board without through-hole cartridge components, a variety of SMD and SMC are mounted on one or both sides of the board.

2、Mixed mounting on both sides

On the A side of the printed circuit board, there are both through-hole cartridge components and various SMT components; on the B side of the printed circuit board, only the smaller SMD transistors and SMC components are assembled.

3. Separate mounting on both sides

On the A side of the printed circuit board, only through-hole cartridge components are mounted, while small SMT components are mounted on the B side of the printed circuit board.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve