- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

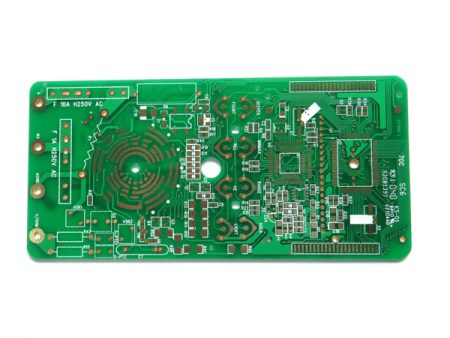

The price of PCB is what many buyers have been confused about. Many people will also question how these prices are calculated when placing an order online. Let’s talk about the components of PCB price together.

1.The different materials used in PCB cause the diversity of prices

For example, the sheet material of the ordinary double-sided board generally has FR4 (Shengyi, Kingboard, Guoji, three prices from top to bottom), the thickness varies from 0.2mm to 3.0mm, and the copper thickness varies from 0.5oz to 3oz. All these have caused a huge price difference in the sheet material. In terms of solder mask ink, there is also a certain price difference between ordinary thermosetting oil and photosensitive green oil.

2. Different surface treatment processes cause price diversity

Common ones are OSP (anti-oxidation), lead spray tin, lead-free tin spray (environmental protection), gold plating, immersion gold, and some combination processes, etc. The prices of the above processes become more expensive.

3. The price diversity caused by the difficulty of PCB

Two kinds of circuit boards have 1000 holes. One board has a hole diameter of more than 0.2mm and the other board has a hole diameter of less than 0.2mm, which will result in different drilling costs. If most of two circuit boards are the same, but the line width and line spacing are different. One is greater than 4mil, and the other is less than 4mil, which will also cause different production costs.

And some designs that do not follow the ordinary board process flow are also need extra money, such as half-holes, buried blind holes, holes in the disk, and buttons board printing carbon oil.

4. The different thickness of copper foil causes price diversity

Common copper and platinum thicknesses are: 18um (1/2OZ), 35um (1OZ), 70um (2OZ), 105um (3OZ), 140um (4OZ), etc. The thickness of the above copper foil becomes more expensive as it goes back.

5. Customer’s quality acceptance criteria

Commonly used are IPC2, IPC3, enterprise standard, military standard, etc. The higher the standard, the higher the price.

6. Mold Fee and Test Stand

(1) Mold fee: For samples and small batches, the general plate factory uses the drilling and milling shape, and there is no additional milling fee. When making large quantities, mold punching is required, so there is a set of mold costs. The board factory generally quotes above RMB 1,000.

(2) Test fee: The prototype is generally tested by flying probes, and the board factory generally charges 100-400 yuan for the test fee; the test rack must be opened for testing in batches, and the general board manufacturer’s quotation is between 1,000-1,500 yuan.

7. Price differences caused by different payment methods

The shorter the payment method, such as cash payment, the lower the price.

8. Order Quantity/Delivery Time

(1) The smaller the quantity, the more expensive the price is. Because even if it is 1PCS, the board factory has to do the engineering data, and the film is out, whichever process is indispensable.

(2) Delivery date: The data delivered to the PCB factory must be complete (GERBER information, the number of layers of the board, the thickness of the board, what to do with the surface treatment, the color of the ink, the color of the characters and some special requirements must be clearly written)

Summarize:

From the above discussion, it is not difficult to see that the diversity of PCB processing prices has its inherent inevitable factors. This article can only provide a rough price range for reference. Of course, the specific price is still in direct contact with the manufacturer.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve