- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

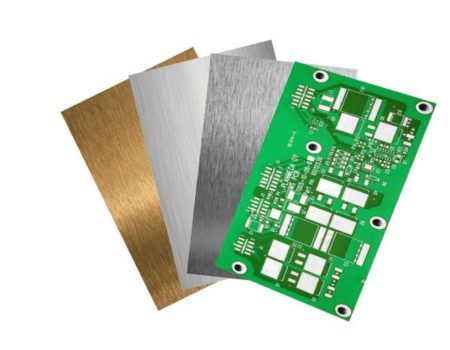

Generally, substrate materials for printed boards can be divided into two categories:

Rigid substrate materials and flexible substrate materials. An important variety of rigid substrate materials is copper clad laminate. It is made of reinforced material (Reinforeing Material), impregnated with resin adhesive, dried, cut, and laminated into a blank, and then covered with copper foil, using steel plate as a mold, and processed by high temperature and high pressure forming in a hot press Into. The prepregs used for general multilayer boards are semi-finished products in the production process of copper clad laminates (mostly glass cloth is impregnated with resin and processed by drying).

Classification of Copper Clad Laminates:

There are many ways to classify copper clad laminates. Usually according to the different reinforcing materials of the board, it can be divided into five categories: paper base, glass fiber cloth base, composite base (CEM series), multi-layer laminate base and special material base (ceramic, metal core base, etc.). If classified according to the different resin adhesives used in the board, the common paper-based CCI. There includes phenolic resin (XPc, XxxPC, FR-1, FR-2, etc.), epoxy resin (FE-3), polyester resin and other types.

Common glass fiber cloth base CCL has epoxy resin (FR-4, FR-5), which is currently the most widely used type of glass fiber cloth base. In addition, there are other special resins (with glass fiber cloth, polyamide fiber, non-woven fabric, etc. as additional materials): bismaleimide modified triazine resin (BT), polyimide resin (PI) , Diphenylene ether resin (PPO), maleic anhydride imine-styrene resin (MS), polycyanate resin, polyolefin resin, etc.

Classified by CCL’s Flame Retardant Performance:

It can be divided into flame-retardant type (UL94-VO, UL94-V1 grade) and non-flame-retardant type (UL94-HB grade). In the past one or two years, with more attention paid to environmental protection issues, a new type of non-bromine-free CCL has been divided into flame-retardant CCL, which can be called “green flame-retardant CCL”. With the rapid development of electronic product technology, there are higher performance requirements for CCL. Therefore, from the performance classification of CCL, it is divided into general performance CCL, low dielectric constant CCL, high heat resistance CCL (normal board L is above 150 ℃), low thermal expansion coefficient CCL (usually used on package substrates) ) And other types.

The above is the introduction of PCB substrate materials, and the choice of PCB substrate materials can directly affect the final quality and application of PCB. This is also one of the important factors that major industries such as electronics and electrical appliances pay more and more attention to the selection of PCB materials.

XPCB Limited is a manufacturer specializing in the production of high-precision double-sided, multi-layer and impedance, blind buried vias, and thick copper circuit boards. The products cover HDI, thick copper, backplanes, rigid-flex combined, buried capacitance and buried resistance, Golden Finger and other kinds of circuit boards, which can meet the needs of customers for all kinds of products.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve