- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

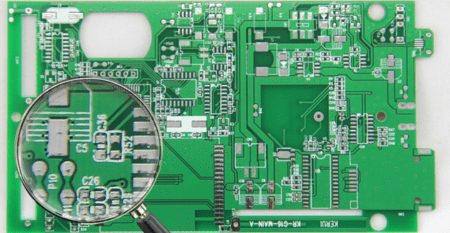

In the production and manufacturing of the PCB circuit board industry, there is a process that is optional (test or not). Today, I will help customers who need to do an analysis, whether it is necessary to choose between testing and not testing when producing circuit boards and what method to choose for testing. Circuit board production is divided into three types, today we will analyze these three types of circuit board production.

Circuit Board Prototyping:

It refers to a sample board with an area of less than 0.6 square meters. For this kind of circuit board prototyping, we can choose flying probe testing. The cost of flying probe testing is relatively small. If it is only a test function, we suggest that the prototypingshould be controlled within 0.2 square meters. In this case, we test it for free. Of course, there is another situation where the circuit board drawing design is confirmed to be no problem, but I just want to make a sample to test the quality of the circuit board manufacturer and the performance of the circuit board, then you can choose to start the test. In this case, choose to open test rack test, so that the cost of a flying probe test can be saved.

Small Batch Production of Circuit Boards:

Small batch production of circuit boards refers to circuit boards with an area from 0.6 square meters and 5 square meters. For this kind of small batch circuit board production, I strongly recommends that you open a test rack for testing. Because the board is used for more than 3 square meters, the flying probe test takes a long time. The cost of flying probe test is relatively high. And if there is still mass production in the future, a lot of test costs can be saved.

Mass Production of Circuit Boards:

The mass production of circuit boards refers to circuit boards with an area of more than 5 square meters. There is only one choice for this kind of board, which is test! That is the choice of opening a test rack to test the circuit board. Let us talk about why we need it. Choose test. I think everyone knows that there are more than 10 processes in the production of circuit boards. If you don’t understand, you can check the circuit board production process. Each process must be controlled to be fully qualified to ensure the quality of the production circuit board, but it is always artificial. There will be some problems, and 100% qualification cannot be guaranteed, then the problems that arise need to be tested to ensure the quality. If you do not test, it may cause some cost increases, such as the increase in SMT assembly costs, the increase in component costs, etc. So in order to pass the circuit board, we should spend unnecessary waste on reasonable test costs.

XPCB Limited is a manufacturer specializing in the production of high-precision double-sided, multilayer and impedance, blind buried vias, thick copper circuit boards, products covering HDI, thick copper, backplanes, rigid-flex combined, buried capacitance and buried resistance, Golden Finger and other types of circuit boards, which can meet the needs of customers for various products.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve