- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Due to the actual factory production lines, the equipment and potion system used are not exactly the same. Therefore, it is necessary to conduct targeted analysis and processing solutions based on the product and the actual situation. Here are just three common causes of common problems for your reference.

1. Thickness control of electroplated nickel layer.

Everyone must have thought that I am dizzy that the blackened gold plating layer is related with the thickness of the nickel plating layer. In fact, PCB electroplating gold layer is generally very thin, reflecting that many of the problems on the electroplated gold surface are caused by poor performance of electroplated nickel. Generally, the thinning of the electroplated nickel layer will cause the appearance of the product to be whitish and black. Therefore, this is the first choice for plant engineers and technicians to check. Generally, the thickness of the nickel layer needs to be electroplated to about 5 um to be sufficient.

2. Potion status of electroplated nickel tank.

If the nickel tank potion is not well maintained for a long time, and the carbon treatment is not carried out in time, the nickel layer will easily produce flaky crystals, the hardness of the plating layer will increase, and the brittleness of the plating layer will increase. In severe cases, blackening of the coating will occur. This is because many people tend to overlook the key points of control. It is also often an important cause of problems. Therefore, please carefully check the potion status of your factory’s production line, conduct comparative analysis, and carry out thorough carbon treatment in time to restore potion activity and clean electroplating solution. If you don’t know how to deal with carbon, it would be even bigger problem.

3. Gold cylinder control.

Now it comes to the gold cylinder control. Generally, as long as you maintain good potion filtration and replenishment, the pollution and stability of the gold cylinder will be better than that of the nickel cylinder. But you need to pay attention to check whether the following aspects are good: (1) Are the supplements of the golden cylinder sufficient and excessive? (2) How is the PH value of the potion controlled? (3) How about the conductive salt? If there is no problem with the inspection result, use the AA machine to analyze the impurity content in the solution to margin potion status.

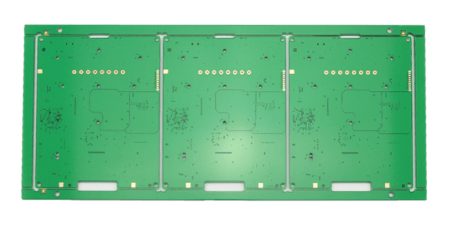

XPCB Limited is a manufacturer specializing in the production of high-precision double-sided, multi-layer and impedance, blind buried vias, and thick copper circuit boards. The products cover HDI, thick copper, backplanes, rigid-flex combined, buried capacitance and buried resistance, Golden Finger and other types of circuit boards, which can meet the needs of customers for various products.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve