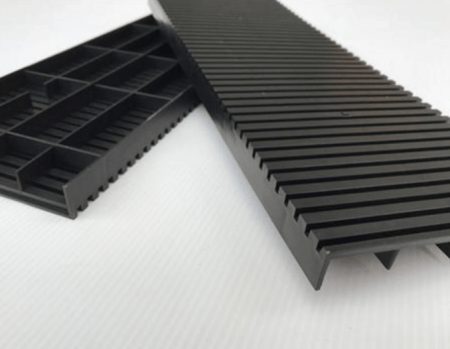

In the process of PCB board processing in the SMT patch processing workshop, in order to protect the PCB board from electrostatic hazards, a PCB tray or a PCB card board will be used for placement. The full name of the card board is anti-static card board. The main function is to reduce the damage to the PCB board due to vibration during transportation and reduce the damage rate. The groove design in the tray saves space and strengthens the fastening between trays. Greatly reduce the incidence of defective products, improve work efficiency, and better improve the production process.

Card board requirements for PCB board in SMT workshop:

1. Conduct an anti-static performance inspection every six months for PCB pallets, anti-static component racks, weekly boxes, and transport vehicle.

2. The anti-static container and anti-static turnover box used by the operator should be cleaned regularly, and the anti-static table mat, tools and containers should be cleaned with neutral detergent every month.

When choosing a suitable PCB card board, you must choose a suitable one that can ensure the quality of the PCB. The material of the tray must meet the following characteristics:

①High dimensional stability

②Good thermal shock resistance

③Remain flat after repeated use

④Corrosion resistance (flux and cleaning agent)

⑤Do not absorb moisture

In the PCB manufacturing and assembly process of the SMT patch processing factory, not only should anti-static pallets be used to ensure the production quality, but also the anti-static protection of the production workshop should be done well. The operators should wear electrostatic wristbands, electrostatic clothing and electrostatic shoes. It can play a role in electrostatic protection for PCB production.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : info@x-pcb.com

© 2024 - XPCB Limited All Right Reserve