- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

First look at the form of the disconnection, then analyze the process in which the disconnection is made, and then analyze the cause of the process in that process. Then check it step by step.

Generally, the disconnection problem is mainly in the filming process. (The reason is that the film is not firmly attached, there are bubbles, and if it is a wet film, there will be garbage pollution.), the exposure process (the film is caused by scratches or garbage, including problems with the exposure machine, insufficient exposure, etc. ), development process (unclear development), etching process (excessive nozzle pressure, too long etching time), plating problems (uneven plating, or adsorption on the surface), improper operation (basically caused by scratches).

The key depends on the form of disconnection, so process engineer experience is very important.

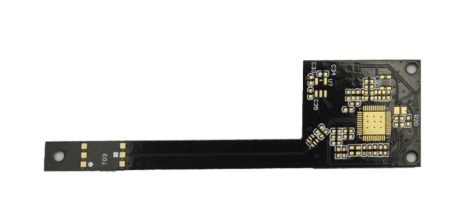

XPCB Limited is a manufacturer specializing in the production of high-precision double-sided, multi-layer and impedance, blind buried vias, and thick copper circuit boards. The products cover HDI, thick copper, backplanes, rigid-flex combined, buried capacitance and buried resistance, Golden Finger and other types of circuit boards, which can meet the needs of customers for various products.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve