- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

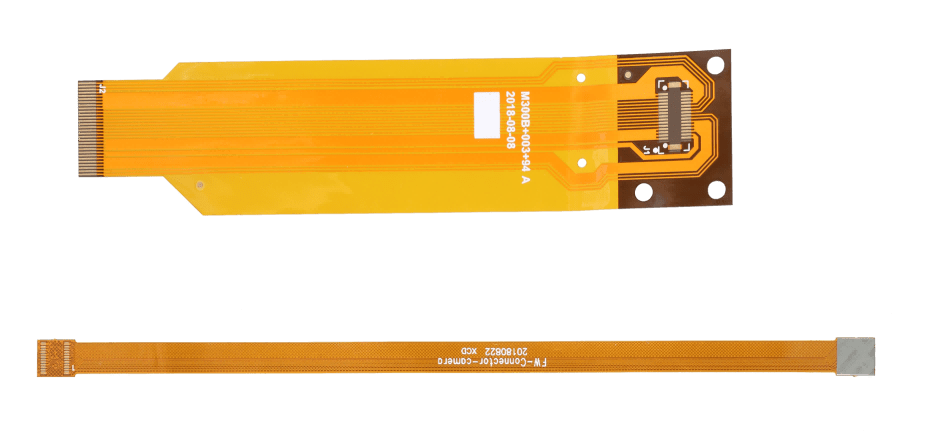

The process of FPC Flexible PCB includes exposure, PI etching, opening, electrical test, punching, appearance inspection, performance test and so on. The production process of the FPC Flexible PCB is related to the performance of the FPC. After the production is completed, it needs to be tested to screen out the unqualified FPC Flexible PCB to ensure that the FPC maintains good performance in the application and plays the best role.

In the FPC Flexible PCB test, a high-current shrapnel micro-needle module with conduction and connection functions can be used to ensure the stability and efficiency of the FPC Flexible PCB test. In the FPC Flexible PCB process, the exposure is to transfer the circuit pattern to the board through the action of the dry film. It is usually carried out by the photosensitive method. After the exposure is completed, the circuit of the FPC Flexible PCB is basically formed. The dry film can transfer the image, and also Protect the circuit during the etching process. PI etching means that under certain temperature conditions, the etching solution is evenly sprayed on the surface of the copper foil through the nozzle, and the oxidation-reduction reaction occurs with the copper, and then the circuit is formed after the film removal treatment. The purpose of the opening is to form the original conductor circuit and the interconnection circuit between the layers. The opening process is often used for the conduction connection of the upper and lower layers of the double-layer FPC.

In addition to the service life, reliability performance and environmental performance of the FPC Flexible PCB, the performance test of FPC also includes folding resistance, flex resistance, heat resistance, solvent resistance, solderability, peeling performance, etc. .

The folding resistance and flex resistance of the FPC Flexible PCB are related to the material and thickness of the copper foil, the type and thickness of the glue used for the base material, and the material and thickness of the insulating base material. In the FPC Flexible PCB assembly process, the double-layer and multilayer FPC copper foils have good symmetry when they are pressed together, so the bending resistance and bending resistance will be better.

The FPC Flexible PCB performance test requires professional equipment. Among them, the high-current shrapnel microneedle module has a stable conduction effect. Its integrated shrapnel design has the characteristics of high overall accuracy and good electrical conductivity. During transmission, it can carry current in the range of 1-50A, and has reliable overcurrent capability. The current flows in the same material body, the voltage is constant, the current has no attenuation, and the performance is stable and reliable.

In small pitches, the high-current shrapnel micro-needle module can cope with the pitch value between 0.15mm-0.4mm and maintain a stable connection. The pin is not stuck and the needle is constantly needled, and the performance and service life are excellent. After the shrapnel is gold-plated and hardened, the average service life can reach more than 20w times, which can greatly improve the test efficiency of the FPC Flexible PCB and it does not need to be replaced frequently in high-frequency tests, so material waste and unnecessary losses can be avoided.

For FPC Flexible PCB testing, both in terms of performance and cost performance, the high-current shrapnel microneedle module is a very reliable choice. It has irreplaceable advantages. It can not only guarantee the stability of the test, but also has a long service life. It can improve the testing efficiency of FPC Flexible PCB and ensure the quality of FPC Flexible PCB.

As a professional FPC soft board manufacturer, XPCB Limited is so honored to have worked together with many of you. At XPCB Limited we are always more than ready to assist our new customers in any way we can. Please feel free to contact us at any time if you have any question.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve