- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

With the rapid expansion of applications such as smartphones, tablet computers, LED TVs, and ultra-thin NB notebooks, leading consumer electronics to develop towards miniaturization, refinement, and portability, global consumer electronics have entered an era of thinness and diversification, bringing more and more market space to Flexible PCB.

Apple is a staunch supporter of flexible circuit board, with as many as 16 FPCs used in its iPhones, making it the world’s largest purchaser of flexible PCB. The world’s top 6 FPC manufacturers are mainly customers. Samsung, Huawei, OPPO, and other manufacturers have also continued to increase the use of FPC in their smartphones under Apple’s demonstration.

As the main growth driver of flexible circuit board, smart phones are benefiting from Apple and its demonstration effect, flexible PCB has penetrated rapidly, and has been able to maintain a high growth rate every year since 2009 years, and it has become the only bright spot in the PCB industry in 17 years, becoming the only category that has achieved positive growth.

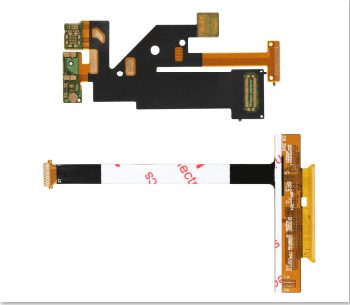

Flexible PCB

Flexible circuit board manufacturing industry appeared in the 60s of the 20th century, the United States and other countries with developed electronic technology were the first to apply FPC to aerospace and military and other high-tech electronic product applications, after the end of the Cold War, FPC began to be used in civilian products. At the beginning of the 21st century, the vigorous development of the consumer electronics industry has pushed the flexible PCB industry into a period of rapid development.

However, due to the continuous increase in production costs in Europe and the United States, the focus of FPC production has gradually shifted to Asia, forming the first wave of flexible PCB industry transfer, and promoting the rapid growth of FPC industries in Japan, South Korea, Taiwan and other countries and regions with good manufacturing foundation and production experience.

In recent years, the production costs of Japan, South Korea and Taiwan have continued to rise, and the FPC industry has started a new round of industrial transfer. FPC manufacturers in developed countries have invested and set up factories in China, and China, as the main host country of the flexible PCB industry, has benefited from the new wave of industrial transfer. At present, the total output value of flexible circuit board in China is in the leading position in the world.

Polyimide Stiffener of flexible pcb

At present, the production process of flexible circuit boards mainly includes cutting, punching, black holes, copper plating, dry film, exposure, development, etching, film removal, decontamination and cleaning, protective film, lamination, pure tin, gold plating, silk screen printing, punching, electrical testing, reinforcing film lamination, functional testing and other processes.

The abbreviation of Flexible Printed Circuit, also known as flexible circuit board, flexible printed circuit board, flexible circuit board, referred to as flexible circuit board or FPC, has the characteristics of high wiring density, light weight and thin thickness.

Based on the vast market of FPC in China, large enterprises in Japan, the United States, and Taiwan have set up factories in China. By 2016, flexible circuit boards, like rigid circuit boards, have made great progress. However, if a new product according to the “start-development-climax-decline-elimination” law, FPC is now in the area between the climax and decline, before there is no product to replace the flexible board, the flexible board to continue to occupy the market share, must be innovative, only innovation can make it jump out of this circle.

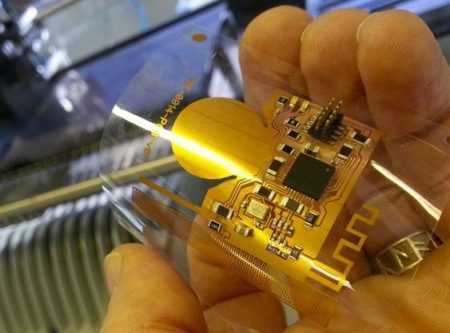

Design of flexible pcb

Thickness. The thickness of the flexible PCB must be more flexible and must be thinner;

Folding resistance. It is the innate characteristic of FPC to bend, and the future flexible PCB must be more resistant to bending, which must exceed 10,000 times, of course, this requires a better substrate;

Price. At this stage, the price of flexible PCB is much higher than that of PCB, and if the price of FPC comes down, the market will be much wider;

Level of craftsmanship. In order to meet the requirements of many aspects, the FPC process must be upgraded, and the minimum aperture and minimum line width/line spacing must meet higher requirements.

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve