- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

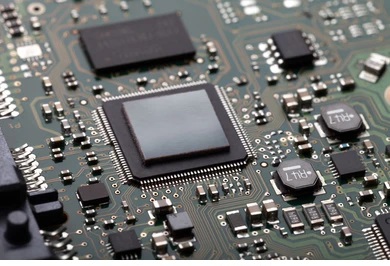

Surface Mount Device (SMD) packaging has become an essential part of modern electronics, enabling the miniaturization of devices, increasing performance, and improving manufacturing efficiency. From consumer electronics to automotive systems, industrial machinery, and telecommunications, SMD components are used across a wide range of applications. In this blog, we will explore the various fields where SMD packaging plays a crucial role and how it is driving innovation in each sector.

Consumer electronics are among the most widespread applications for SMD packaging. Devices such as smartphones, laptops, tablets, smartwatches, and televisions rely heavily on SMD components. The ability to use smaller, more compact components allows for the development of sleek, lightweight, and powerful devices.

Miniaturization: SMD components are smaller than traditional through-hole components, which allows engineers to design more compact devices. For example, smartphones today pack an incredible amount of functionality into a device that is only a few millimeters thick.

Cost Efficiency: The use of automated assembly processes, such as pick-and-place machines, significantly reduces labor costs, making these devices more affordable for consumers.

High Performance: SMD technology allows for high-density circuit designs, meaning that more complex and powerful features can be integrated into a smaller form factor.

As consumer demand for portable, high-performance electronics grows, SMD packaging continues to play a vital role in ensuring that these devices remain at the forefront of technology.

The automotive industry has undergone a major transformation in recent years with the increasing adoption of advanced electronic systems in vehicles. Modern cars now feature numerous electronic components for functions such as infotainment, navigation, driver assistance, safety systems, and engine control. SMD packaging is critical in supporting these complex automotive electronics.

Infotainment Systems: Automotive infotainment systems combine entertainment, navigation, and communication functions. SMD technology is used to assemble the compact and powerful circuits needed for these systems.

Advanced Driver Assistance Systems (ADAS): ADAS relies on sensors, cameras, and processors to enhance vehicle safety. SMD components are used in these systems due to their small size and high performance.

Power Control: SMDs are used in power distribution and management systems to ensure optimal efficiency and performance of the vehicle’s electrical components.

The shift towards electric vehicles (EVs) and autonomous driving technologies further emphasizes the importance of SMD packaging, as these innovations require highly efficient and reliable electronic components.

The telecommunications industry, which encompasses mobile networks, satellite communications, and internet infrastructure, has seen tremendous growth due to the increasing demand for faster and more reliable communication. SMD components are used extensively in telecommunications equipment such as routers, network switches, cell phones, and satellite systems.

Communication Devices: Smartphones, tablets, and other mobile devices are packed with SMD components to ensure fast processing speeds, low power consumption, and compact designs.

Network Infrastructure: Routers, switches, and base stations that form the backbone of the telecommunications network rely on SMDs for high-speed data processing and minimal space utilization.

Signal Processing: SMD components, including capacitors, resistors, and ICs, are used in signal processing equipment to ensure high-quality signal transmission and reception.

With the rapid evolution of 5G technology and the growing demand for high-speed internet, the need for smaller, more efficient, and high-performance telecommunications equipment makes SMD packaging an essential part of the industry’s infrastructure.

The medical field is one of the most demanding industries for electronics, where performance, reliability, and miniaturization are critical. SMD packaging is widely used in medical devices, such as diagnostic equipment, implantable devices, and wearable health trackers, due to its ability to deliver compact, reliable, and precise solutions.

Wearable Health Devices: SMD technology enables the development of smaller, more efficient wearable devices like smartwatches that monitor vital signs such as heart rate, blood pressure, and glucose levels.

Diagnostic Equipment: Advanced diagnostic machines such as MRI scanners, ECG machines, and blood analyzers rely on high-density SMD components to manage complex data processing and ensure accurate results.

Implantable Devices: For devices like pacemakers, hearing aids, and insulin pumps, SMD components offer the small size and durability necessary for implantation into the human body.

SMD packaging ensures that medical devices can be both compact and reliable, helping improve patient care and enabling new innovations in the field of healthcare.

SMD components also play a vital role in industrial electronics, where rugged, reliable, and high-performance devices are necessary for automation, control, monitoring, and power management. Industrial electronics are used in applications such as robotics, factory automation, control systems, and sensors.

Automation Systems: Industrial robots and automated production lines rely on SMD-based control boards to process data and control machinery.

Power Management: SMD components are used in power supplies, converters, and other systems to ensure stable and efficient energy usage in factories and industrial plants.

Sensors and Actuators: Many industrial sensors, including temperature sensors, motion detectors, and pressure sensors, are designed using SMD components for compactness and efficiency.

With the continued rise of Industry 4.0 and the increasing adoption of automation and smart manufacturing, the demand for reliable, compact, and high-performance electronics in the industrial sector will continue to drive the use of SMD packaging.

Aerospace and defense systems require electronics that can withstand harsh environments, including extreme temperatures, high radiation, and mechanical stress. SMD packaging is crucial in developing reliable, high-performance components for military systems, satellites, drones, and avionics.

Satellite Systems: Satellites require small, robust, and reliable electronics for communication, navigation, and monitoring purposes, all of which rely on SMD components.

Drones and UAVs: Unmanned aerial vehicles (UAVs) used for surveillance, reconnaissance, or transport rely on compact and lightweight electronics designed with SMD technology.

Avionics: Modern aircraft have complex avionics systems that require the integration of numerous electronic components, all of which are efficiently packaged using SMD technology.

The need for compactness, reliability, and precision in the aerospace and defense sectors makes SMD packaging a vital part of the development of advanced military and space systems.

SMD packaging is a cornerstone of modern electronics, with applications spanning a wide range of industries, including consumer electronics, automotive, telecommunications, healthcare, industrial automation, and defense. As electronic devices continue to shrink in size while increasing in functionality, the importance of SMD packaging only grows. The ability to create compact, efficient, and high-performance components allows engineers to push the boundaries of innovation in various fields, leading to smarter, more connected, and more capable devices that will shape the future of technology.

Take Your Projects to New Heights with XPCB Limited

XPCB Limited offers top-notch PCB manufacturing, quick-turnaround prototyping, and turnkey PCBA services designed to make your projects shine. Count on us to bring your ideas to life with efficiency and quality. Your success matters to us, and we’re here to make your innovation journey smooth and rewarding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve