The automotive industry is undergoing a technological transformation driven by the demand for smarter, safer, and more efficient vehicles. At the heart of this evolution lies a critical component: Flexible Printed Circuit Boards (Flex PCBs). These advanced PCBs are redefining automotive electronics by enabling compact designs, reliable performance, and seamless integration of high-tech systems.

This blog explores how Flex PCB solutions are powering automotive innovations, their benefits, applications, and role in shaping the future of mobility.

Flex PCBs: Enabling the Next Generation of Automotive Electronics

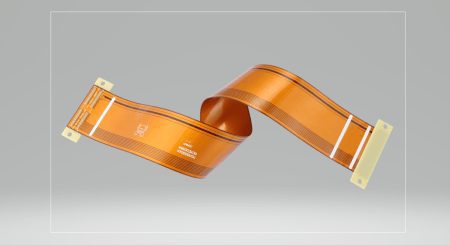

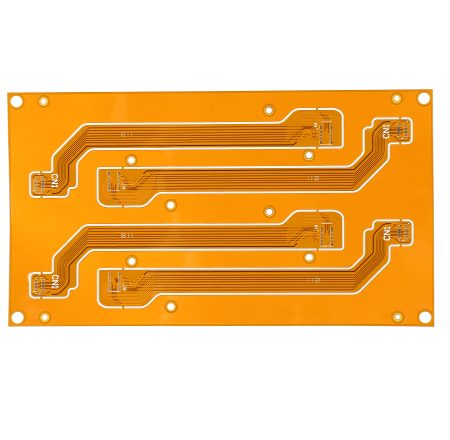

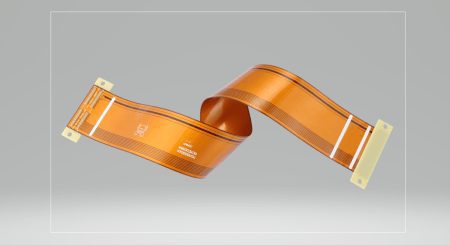

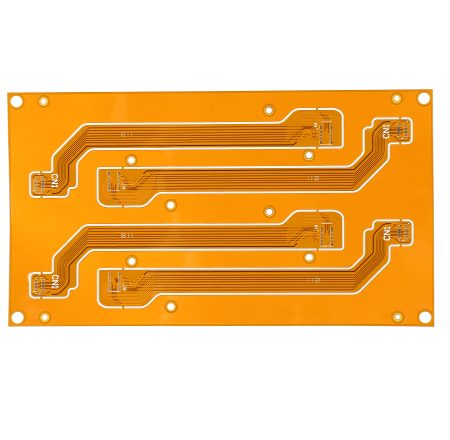

Flex PCBs are lightweight, bendable circuit boards that can be folded, twisted, or shaped to fit into unconventional spaces. Their adaptability makes them a cornerstone in the design and functionality of modern automotive systems.

Why Flex PCBs Are a Game-Changer in Automotive Electronics

- Space Efficiency: Flex PCBs eliminate bulky wiring and connectors, making them ideal for the compact layouts of modern vehicles.

- Durability: Withstand vibrations, extreme temperatures, and harsh environmental conditions.

- High Reliability: Reduce failure points by integrating components into a single flexible circuit.

- Design Flexibility: Allow creative layouts and seamless integration of curved surfaces, such as dashboards and infotainment systems.

- Weight Reduction: Contribute to overall vehicle efficiency by minimizing the weight of electronic components.

Key Automotive Applications of Flex PCBs

1. Advanced Driver-Assistance Systems (ADAS)

ADAS is the backbone of vehicle safety and automation, incorporating features like lane-keeping assist, adaptive cruise control, and collision warning systems. Flex PCBs play a crucial role by:

- Connecting high-resolution cameras, LiDAR, and radar sensors.

- Providing robust performance in dynamic and challenging environments.

2. Infotainment and Connectivity

Modern vehicles are equipped with sophisticated infotainment systems, offering touchscreen displays, voice recognition, and wireless connectivity. Flex PCBs enable:

- Compact designs that fit sleek dashboards.

- High-speed data transmission with minimal interference.

3. Electric Vehicles (EVs)

In EVs, Flex PCBs are integral to battery management systems (BMS) and powertrain control. They help:

- Optimize energy efficiency by managing voltage and temperature.

- Provide reliable connections in compact and high-power environments.

4. Lighting Systems

Flex PCBs enable innovative automotive lighting designs, including LED headlights, taillights, and ambient interior lighting. Their flexibility allows:

- Integration into complex and curved surfaces.

- Enhanced durability in high-temperature conditions.

5. Autonomous Driving Technologies

Autonomous vehicles rely on a network of sensors, cameras, and control units for navigation and decision-making. Flex PCBs provide:

- Reliable connections between critical systems.

- Compact layouts that support miniaturized components.

Benefits of Flex PCBs in Automotive Electronics

- Improved Reliability

Automotive environments subject electronics to constant stress from vibration, heat, and moisture. Flex PCBs are designed to handle these challenges, ensuring consistent performance over time.

- Simplified Assembly

Flex PCBs streamline the assembly process by integrating multiple functions into a single flexible circuit, reducing the need for connectors and cables.

- Cost Efficiency

While the initial cost of Flex PCBs may be higher, their durability and simplified assembly result in long-term savings by reducing maintenance and failure rates.

- Support for Advanced Features

Flex PCBs enable cutting-edge technologies like real-time data transmission, adaptive interfaces, and smart sensors, making vehicles more intelligent and user-friendly.

- Enhanced Safety

By ensuring reliable performance in critical systems like ADAS and autonomous driving, Flex PCBs contribute to safer driving experiences.

Challenges in Flex PCB Implementation

While Flex PCBs offer numerous advantages, their implementation comes with challenges:

- Higher Manufacturing Complexity

Flex PCBs require specialized manufacturing processes and materials, which can increase production costs and lead times.

- Design Considerations

Engineers must account for factors like bending radius, thermal expansion, and electrical performance during the design phase.

- Material Limitations

The choice of materials affects flexibility, durability, and thermal resistance, posing constraints for some applications.

- Cost Constraints

Despite long-term benefits, the initial investment in Flex PCBs may deter adoption for cost-sensitive applications.

The Future of Flex PCBs in Automotive Innovations

As vehicles become more connected, automated, and energy-efficient, the role of Flex PCBs is set to expand. Emerging trends that will shape the future of Flex PCBs in automotive applications include:

- Integration with IoT and Smart Systems

Flex PCBs will enable seamless communication between IoT sensors, processors, and networks, enhancing vehicle connectivity and real-time data sharing.

- High-Speed Data Transmission

As vehicles adopt 5G and advanced communication technologies, Flex PCBs will play a pivotal role in managing high-speed data with minimal latency.

- Sustainability

The development of eco-friendly materials and recycling methods for Flex PCBs will align with the automotive industry’s focus on sustainability.

- Advanced Manufacturing Techniques

Innovations like 3D printing and additive manufacturing will enable more complex and customized Flex PCB designs.

- Enhanced Integration for EVs and Autonomous Vehicles

Flex PCBs will support the increasing complexity of EV powertrains and autonomous vehicle systems by offering compact and efficient solutions.

Conclusion

Flex PCBs are more than a technological advancement—they are a transformative force in the automotive industry. By enabling compact designs, reliable performance, and innovative features, Flex PCBs are driving the future of mobility.

From ADAS and EV systems to infotainment and autonomous technologies, Flex PCBs provide the foundation for safer, smarter, and more connected vehicles. As the industry continues to evolve, investing in cutting-edge Flex PCB solutions will be essential for automakers striving to stay ahead in a competitive and rapidly changing market.

Quick-Turnaround Prototyping Made Easy with XPCB Limited’s Expertise

When time is critical, XPCB Limited delivers. Our quick-turnaround prototyping services are designed to meet tight deadlines without sacrificing quality. Equipped with state-of-the-art facilities and a skilled team, we ensure your PCB prototypes are built accurately and efficiently. With XPCB Limited, you’ll never have to worry about delays in bringing your ideas to life.