- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Flexible printed circuits are found in everything from cars, VCR’s, camcorders, smart devices and also SLR cams to sophisticated army and avionics systems. High-profile applications of flexible circuits are many. one instance is the application of flexible-circuit modern technology in a rigid-flex wire harness utilized on Sojourner, the robot that strolled the surface of Mars gathering data during the summertime of 1997.

Question still exists concerning what constitutes a flexible circuit. When asked to describe a flexible circuit, the picture in many people’s minds will be of a bendy printed circuit, generally containing a flexible film with a pattern of copper conductors on it.

While the image is far from the truth, in order to better understand what flexible circuits is, it is important to know all the basic material used.

Part1 Insulating Substrate

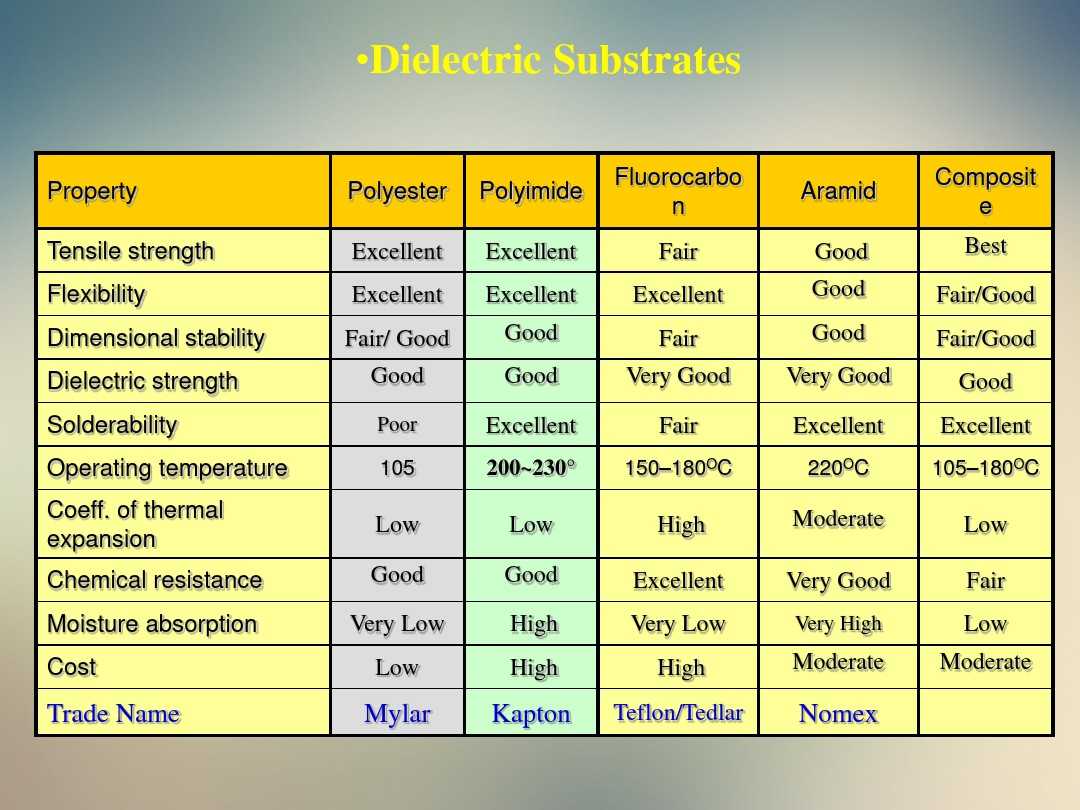

The insulating substrate is a flexible insulating film. As the insulating carrier of the circuit board, the choice of flexible dielectric film requires a comprehensive investigation of the heat resistance, coverage, thickness, mechanical and electrical properties of the material. Nowadays, polyimide (PI: Polyimide, trade name Kapton) film, polyester (PET: Polyester, trade name Mylar) film and polytetrafluoroethylene film are commonly used in engineering. Generally, the film thickness is selected in the range of 0.0127~0.127mm (0.5~5mi1).

Part2 Adhesive

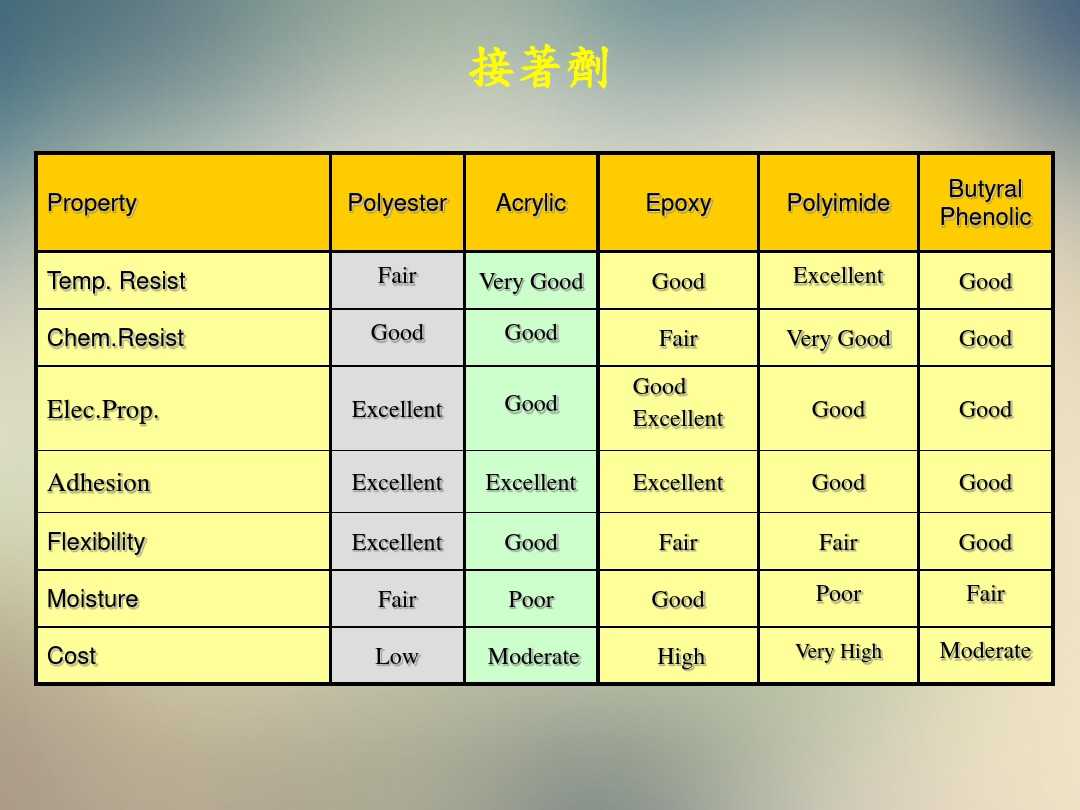

The function of the adhesive sheet is to bond the film and the metal foil, or bond the film and the film (cover film). Different types of adhesive sheets can be used for different film substrates. For example, polyester adhesive sheets are different from polyimide adhesive sheets. Polyimide substrate adhesive sheets can be divided into epoxy and acrylic. The choice of bonding sheet is mainly to investigate the fluidity of the material and its thermal expansion coefficient. There are also polyimide copper clad laminates without adhesive sheets, which have better chemical resistance and electrical properties. The performance comparison of common flexible adhesive sheets is shown in the table below. Because acrylic adhesive sheets have a low glass transition temperature, a large amount of contamination generated during the drilling process is not easy to remove, which affects the quality of metallized holes, and other adhesive materials are unsatisfactory, so , Polyimide materials are commonly used in interlayer bonding sheets of multilayer flexible circuits. Because they are matched with polyimide substrates, their CTE (Coefficient of Thermal Expansion) is consistent, which overcomes the problem of dimensional instability in multilayer flexible circuits. , And other properties are satisfactory.

Part3 Copper Foil

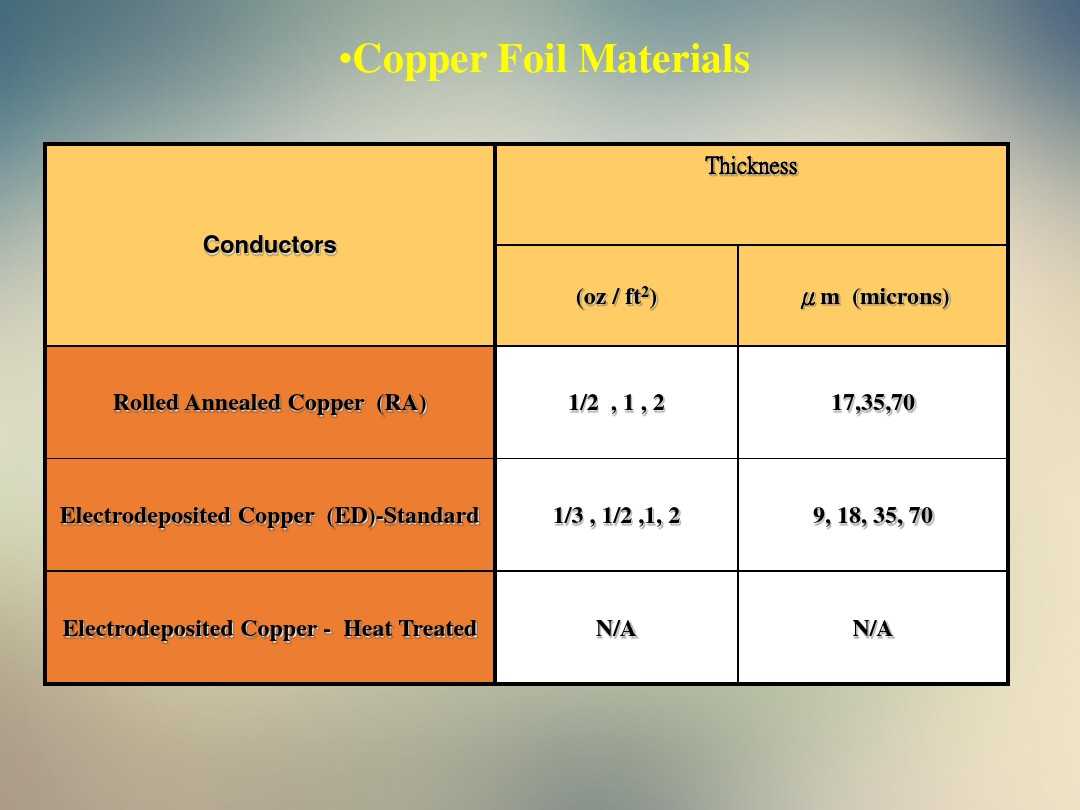

Copper foil is a conductive layer that covers and adheres to the insulating substrate, and then forms conductive lines through selective etching. Most of this kind of copper foil is rolled copper foil or electrolytic copper foil. The ductility and bending resistance of rolled copper foil are better than that of electrolytic copper foil. The elongation of rolled copper foil is 20%-45%, and the elongation of electrolytic copper foil is 4%-40%. The most commonly used copper foil thickness is 35um (10z), and there are also thin 18um (0.50z) or 70um (2oz) thick, or even 105um (30z). Electrolytic copper foil is formed by electroplating. The crystal state of copper particles is vertical needle-shaped, which is easy to form vertical line edges during etching, which is beneficial to the production of precision circuits; but when the bending radius is less than 5m or dynamic deflection, needle-shaped The structure is prone to breakage; therefore, rolled copper foil is mostly used for flexible circuit substrates, and the copper particles are in a horizontal shaft-like structure, which can adapt to multiple windings.

Part4 Cover Layer

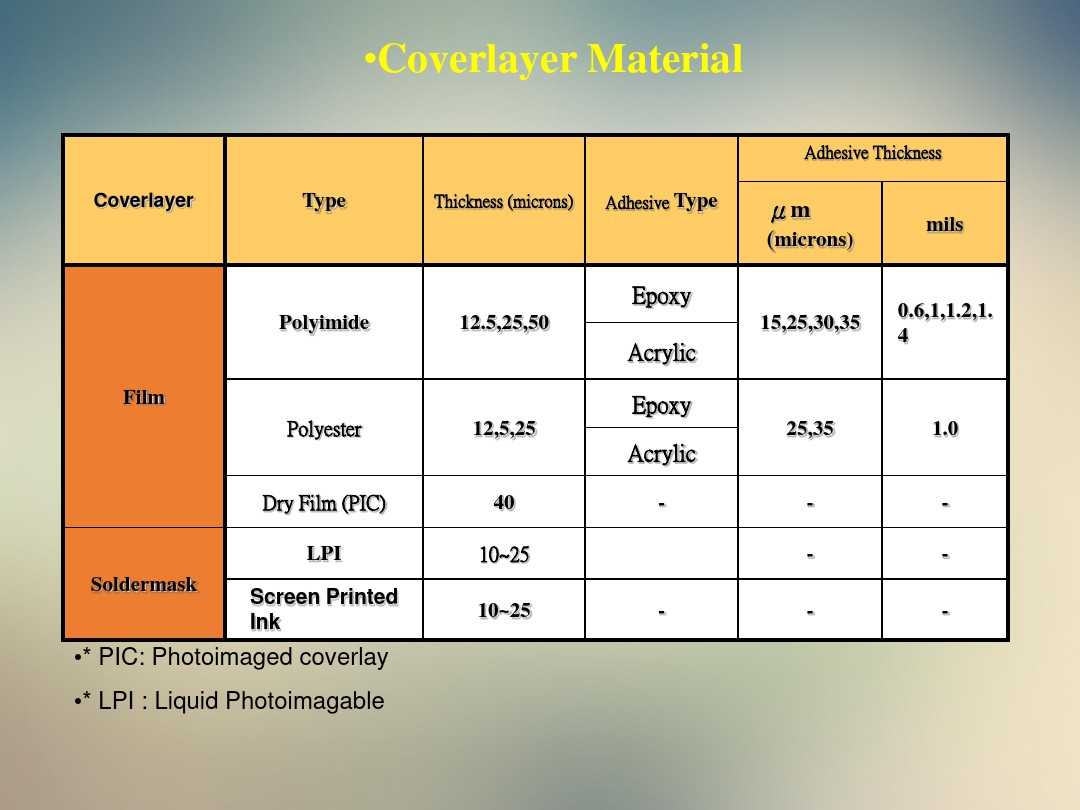

The covering layer is an insulating protective layer covering the surface of the flexible printed circuit board, which protects the surface wires and increases the strength of the substrate. There are generally two types of protective materials for outer graphics. The first type is dry film type (covering film), which is made of polyimide material, which does not require adhesives and is directly laminated with the circuit board to be protected after etching. Lamination. This kind of cover film needs to be pre-formed before pressing, and the exposed parts need to be welded, so it cannot meet the requirements of finer assembly. The second type is the photosensitive development type. The first type of photosensitive development type is to expose the welding part through photosensitive development method after covering the dry film with a laminator to solve the problem of high density assembly; the second type is liquid screen printing type covering material, which is commonly used There are thermosetting polyimide materials, as well as special solder resist inks for photosensitive and developing flexible circuit boards, which can better meet the requirements of fine-pitch, high-density assembly of flexible boards.

Part5 Stiffener

The reinforcement board is bonded to the local board of the flexible board to super support and strengthen the flexible film substrate, which is convenient for the connection, fixation or other functions of the printed board. Reinforcement board materials are selected according to different purposes. Commonly used polyester, polyimide sheet, epoxy glass fiber cloth board, phenolic paper board or steel plate, aluminum board, etc.

XPCB Limited is a high-quality flexible circuit board manufacturer based in China. We can offer a quick-turn prototyping service from single-side flex PCB, double-sided flexible circuit, 3 layer ,4 layer and higher layer count FPC. Don’t hesitate to contact us below if you need FPC fabrication service.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve