- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

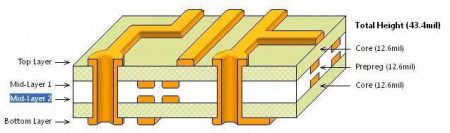

Multilayer PCBs (Printed Circuit Board) is a circuit board composed of multiple layers of substrates, conductive layers, and insulating layers stacked alternately, and its advantages and disadvantages are as follows compared with single-layer PCB:

Higher density and smaller size: Multilayer PCBs can accommodate more components and circuits in the same area, resulting in higher density and smaller size.

Better electrical performance: In a multi-layer PCB, each layer is connected to each other through electrolytic copper holes, which can effectively reduce resistance and inductance, and improve signal transmission speed and stability.

Higher reliability: Multilayer PCBs can better resist interference and noise, and at the same time, they can also better distribute heat, thus improving the reliability and stability of the circuit.

Greater flexibility: Multilayer PCBs can flexibly design circuit layouts, with different circuits layered as needed, allowing for greater flexibility and customizability.

Higher cost: Since multilayer PCBs require more processes and materials, their production costs are also relatively higher. In addition, multi-layer PCBs require more design time and labor, further increasing costs.

More complex designs: The design of multilayer PCB requires a higher level of technology and experience, as well as more time and effort. Multilayer PCB require more layers of design, and need to consider issues such as signal and power interfaces, wiring, and electromagnetic compatibility, so their design complexity is relatively higher.

Higher manufacturing difficulty: Multilayer PCBs require higher manufacturing technology and equipment, such as drilling, stacking, and pressing the inner layer through via. In addition, the manufacturing process of multilayer PCBs also requires higher quality control and inspection to ensure their electrical performance and reliability.

More difficult to debug and maintain: In a multilayer PCB, the connections between different layers are more difficult to check and repair, so if something goes wrong, it can be more cumbersome to fix. Due to the complexity of multilayer PCBs, their commissioning and maintenance are also relatively more difficult. Especially when a component needs to be replaced, the multi-layer PCB needs to be disassembled for repair or replacement.

Higher electromagnetic radiation: The current in a multilayer PCB will flow between different layers, resulting in higher electromagnetic radiation that may cause interference to surrounding electronics.

In general, multilayer PCBs have higher density, better electrical performance, reliability, and flexibility than single-layer PCBs, but they also have disadvantages such as high cost, complex design, and difficult maintenance. Therefore, when choosing a PCB, it is necessary to consider various factors according to the actual needs and choose the most suitable solution.

Higher density: Multilayer PCBs can increase the density of the board by increasing the number of circuits while reducing the size of the board.

Higher reliability: Multilayer PCBs can reduce crosspoints on the board by layering, which can reduce interference and noise on the board.

Higher impedance control: The multi-layer PCB can be routed in the inner layer, which reduces the delay and impedance change of signal transmission, and improves the stability of the signal.

Better heat dissipation: Multilayer PCBs can improve the heat dissipation performance of the circuit board by setting a heat dissipation layer on the inner layer.

Higher functionality: Multilayer PCB can add special layers such as power layer, ground layer, signal layer and so on inside the board to achieve more functions, such as protection, isolation, filtering, etc.

Take Your Projects to New Heights with XPCB Limited

XPCB Limited offers top-notch PCB manufacturing, quick-turnaround prototyping, and turnkey PCBA services designed to make your projects shine. Count on us to bring your ideas to life with efficiency and quality. Your success matters to us, and we’re here to make your innovation journey smooth and rewarding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve