- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

The core equipment for fast printed circuit board processing is the “circuit board stereotype machine”, referred to as the “stereotype machine”. Due to the numerous names of similar devices on the market and the vastly different performances, it is easy to confuse customers who really need circuit board stereotypes. Therefore, it is necessary for us to make some explanations for this.

There are many names for engraving machine tools in the market-“engraving machine”, “PCB engraving machine”, “engraving machine”, “circuit board engraving machine”, “circuit board engraving machine”, “PCB board making machine” “Model processing machine”, “circuit board processing machine”, “circuit board comprehensive processing machine”, “PCB cutting machine”, and even the name “carving machine”.

Many people regard the “engraving machines” used in the fields of advertising, seals, molds, furniture, advertising decoration and handicrafts manufacturing as the same thing as the “engraving machines” used in the field of electronic microwave communication. In fact, they are processing equipment in different fields. There are many differences between the two. The main difference is the processing accuracy. The former has an accuracy of several tens of microns, and the latter has an accuracy of several microns or even smaller. In terms of processing materials, the former is suitable for engraving PVC, acrylic, wood, marble and other materials, and the latter is more accurate. It is suitable for making various copper clad circuit boards. In terms of power, the former is generally larger. The types of tools used are also different, the former has more types of tools and larger sizes, and the latter has a standard 1/8″ shank diameter. There are also many differences between the two devices in the motor and motion system control.

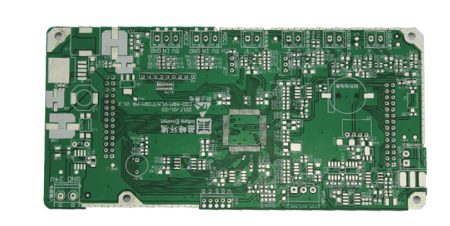

In general, the circuit board engraving machine is the hardware component of the CNC machining center used in the field of electronic production, and it differs from other hardware systems, as well as the CAM software system together constitutes the peripheral CAM (Computer Aided Manufacturing) system of the EDA/CAD design system.

There are also various names for the cutters used in the cutting machine. According to the processing method, they should be divided into two categories “spiral drill” and “milling cutter”. Used for milling surface graphics), “Flat Mill” (End Mill, mainly used to strip surface copper or other materials) and “Contour router” (used by contour router for cutting plates).

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve