- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Soldering machines play a crucial role in the electronics manufacturing process, particularly in the assembly of printed circuit boards (PCBs). These machines are essential for ensuring reliable connections between electronic components. Depending on their working principles and application requirements, soldering machines can be classified into several types. This blog will discuss the main types of soldering machines, along with important considerations for their operation.

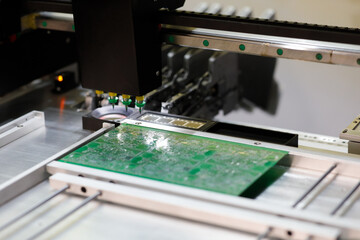

Wave soldering machines are primarily used for soldering through-hole components (THD) and some surface mount devices (SMD). The machine operates by creating a wave of molten solder that the PCB passes over, allowing the solder to make contact with the leads of the components.

Temperature Control: It’s crucial to maintain an appropriate solder temperature to prevent damage to components or the PCB itself. Overheating can lead to issues like component failure or thermal stress.

Flux Selection: The right flux is essential for ensuring good solder joints. It helps to remove oxidation and improve wetting properties. Make sure to choose flux that is compatible with the solder and components used.

Regular Maintenance: Regular cleaning and maintenance of the wave soldering machine are necessary to ensure optimal performance. This includes checking for any blockages or buildup in the solder pot and wave generation components.

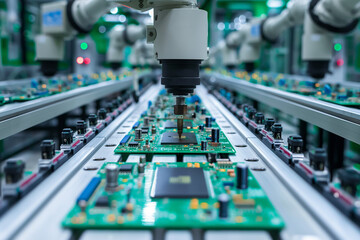

Reflow soldering machines are primarily used for soldering surface mount devices (SMD). The process involves several stages: preheating, soaking, reflowing, and cooling. During reflow, solder paste applied to the PCB melts and creates strong solder joints.

Solder Paste Application: Ensure that the solder paste is applied uniformly across all pads to prevent issues like cold solder joints or voids.

Temperature Profile: Regularly calibrate temperature sensors to ensure that the reflow profile is accurate. An incorrect temperature profile can lead to poor solder quality or damaged components.

Atmospheric Control: Monitor the atmosphere during the reflow process to prevent oxidation of solder and components. An inert atmosphere can help achieve better solder quality.

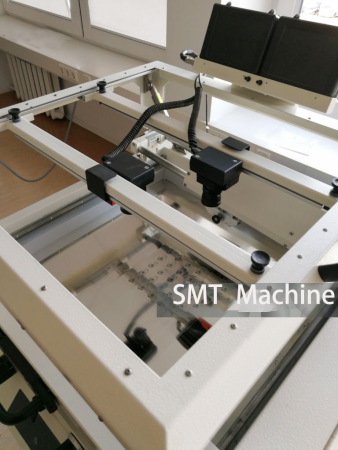

Selective soldering machines are used to solder specific areas of a PCB, making them ideal for mixed technology applications involving both THD and SMD. They use either a nozzle or a soldering head to apply solder directly to the desired areas.

Surface Cleanliness: Ensure that the soldering area is clean to enhance solder joint quality. Contaminants can lead to poor adhesion and solder defects.

Nozzle Maintenance: Regularly check and clean the nozzle to prevent clogging, which can affect the precision of the solder application.

Solder Temperature: Before soldering, make sure the solder temperature is appropriate to avoid overheating components or creating poor joints.

Manual soldering stations are suitable for low-volume production or prototyping. Operators use soldering irons or guns to manually solder components onto the PCB.

Temperature and Power Settings: Ensure that the soldering tools are set to the correct temperature and power levels to prevent damage to components.

Operator Skill: Operators should be trained in proper soldering techniques to minimize the risk of defects such as cold solder joints or overheating components.

Tool Maintenance: Regularly replace solder tips and clean the tools to maintain solder quality and efficiency.

Different types of soldering machines serve specific purposes in electronics manufacturing, each with its advantages and challenges. When using soldering machines, attention to temperature control, solder material selection, and equipment maintenance is essential for ensuring high-quality solder joints and overall production efficiency. As electronic products become more compact and integrated, the choice of soldering technology and equipment will increasingly influence product quality and reliability. Understanding the various types of soldering machines and their operational considerations is vital for manufacturers aiming to stay competitive in the rapidly evolving electronics market.

Your Trusted Partner for PCB Success: XPCB Limited

Let XPCB Limited be your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve