- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

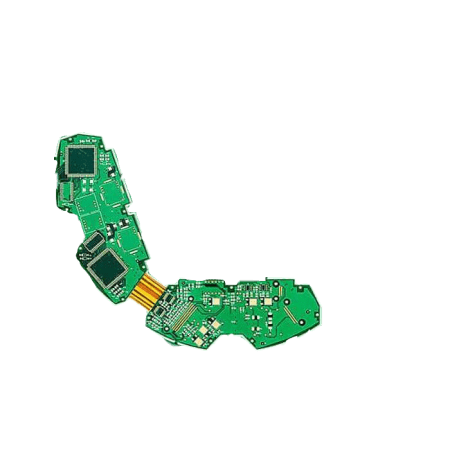

As electronic devices become more complex and compact, the need for innovative circuit board designs has grown exponentially. Among these, Rigid-Flex Printed Circuit Boards (PCBs) have emerged as a versatile solution, enabling cutting-edge applications across industries. However, designing and manufacturing these advanced PCBs require more than just technical expertise—it demands collaboration with seasoned electronics professionals.

In this blog, we explore the importance of working with electronics experts to create advanced rigid-flex PCB solutions, the benefits of these partnerships, and the industries reaping their rewards.

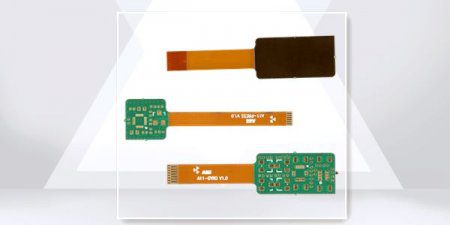

Rigid-flex PCBs combine the robustness of rigid boards with the adaptability of flexible circuits in a single solution. This hybrid design offers exceptional reliability, compactness, and performance for modern applications.

Rigid-flex PCB design involves balancing rigid and flexible layers, optimizing signal integrity, and ensuring mechanical stability. Electronics experts bring in-depth knowledge to address these challenges effectively.

Experts utilize advanced design tools, simulation software, and state-of-the-art manufacturing techniques to produce high-quality PCBs that meet stringent industry standards.

Every application has specific requirements, from thermal management to impedance control. Collaborating with experienced professionals ensures tailored solutions that meet these unique demands.

Electronics experts simplify the development cycle by integrating design, prototyping, testing, and manufacturing processes, reducing time-to-market.

Seasoned professionals offer valuable insights into industry trends, emerging technologies, and best practices, helping companies stay competitive in their fields.

In automotive systems, rigid-flex PCBs are integral to:

Electronics experts help design PCBs that withstand the harsh conditions of automotive environments while delivering reliable performance.

Rigid-flex PCBs are essential for:

Collaboration with experts ensures these PCBs meet rigorous standards for durability and reliability.

Applications include:

Experts contribute to designing compact, biocompatible, and reliable rigid-flex PCBs for life-critical applications.

Rigid-flex PCBs power:

Electronics professionals enable sleek, functional designs that enhance user experiences.

Applications include:

Experts ensure these PCBs deliver consistent performance in demanding industrial environments.

Collaboration with electronics experts will continue to be a cornerstone of innovation in rigid-flex PCB technologies. Key trends shaping the future include:

Advanced rigid-flex PCB solutions are transforming industries by enabling robust, compact, and innovative electronic systems. However, achieving optimal results requires expertise, collaboration, and cutting-edge technology.

By partnering with electronics experts, companies can streamline the development process, access tailored solutions, and stay ahead in competitive markets. Whether it’s for autonomous vehicles, medical implants, or next-generation consumer devices, expert-driven rigid-flex PCB designs are paving the way for a smarter and more connected future.

XPCB Limited: Advanced PCB Manufacturing to Simplify Your Journey

Navigating the complexities of PCB production has never been easier. XPCB Limited combines advanced PCB manufacturing technology with streamlined processes to offer solutions that meet your exact requirements. From prototypes to mass production, we are committed to quality, speed, and affordability. Trust XPCB Limited to make your PCB journey simple and successful.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve