- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

The Printed Circuit Board Assembly (PCBA) industry plays a critical role in the electronics manufacturing landscape. To ensure quality, reliability, and safety, adherence to established standards is essential. These standards can be categorized into common standards, which are widely accepted across the industry, and specialized standards that cater to specific applications or requirements. In this blog, we will explore both categories and their significance.

The Institute for Printed Circuits (IPC) sets many of the most recognized standards in the PCBA industry. These include:

IPC-A-610: This standard outlines the acceptability criteria for electronic assemblies. It provides guidelines for the appearance and quality of solder joints, ensuring consistency and reliability in assembly.

IPC-2221: A general design standard for PCBs, IPC-2221 offers guidelines for the layout, materials, and manufacturing processes, ensuring that boards meet necessary performance requirements.

IPC-J-STD-001: This standard covers soldering and assembly processes, detailing best practices for achieving high-quality solder joints and assemblies.

The International Organization for Standardization (ISO) develops various standards that apply to quality and environmental management:

ISO 9001: This quality management standard ensures organizations can consistently deliver products that meet customer and regulatory requirements.

ISO 14001: Focused on environmental management, this standard helps organizations reduce their environmental impact, an increasingly important aspect in the electronics industry.

Underwriters Laboratories (UL) develops safety standards that apply to PCBs:

UL 94: This standard assesses the flammability of plastic materials used in electrical devices, ensuring safety in case of fire.

UL 796: Specific to printed circuit boards, this standard sets forth safety requirements for PCB materials and their applications.

While common standards provide a solid foundation for quality and safety, specialized standards address unique needs in specific sectors:

MIL-STD-202: This military standard outlines testing methods for electronic components, ensuring that they can withstand harsh environments.

MIL-PRF-31032: This specification details performance requirements for military-grade PCBs, which must meet rigorous durability and reliability criteria.

AEC-Q100: This standard focuses on the qualification of integrated circuits for automotive applications, ensuring that components can operate reliably in challenging conditions.

RoHS Compliance: The Restriction of Hazardous Substances directive restricts specific hazardous materials in electronic products, promoting safer alternatives.

REACH Regulations: This European Union regulation governs the registration, evaluation, and restriction of chemicals used in manufacturing, ensuring environmental and health safety.

Adhering to common and specialized standards is vital for success in the PCBA industry. Common standards, such as those set by IPC and ISO, provide a foundation for quality and safety across all sectors. In contrast, specialized standards cater to specific industries, ensuring that unique requirements are met.

As technology continues to evolve, the importance of these standards will only grow. Manufacturers must stay informed about current standards and any changes that may arise to maintain compliance and competitiveness. By prioritizing quality and safety through adherence to these standards, companies can foster trust with their clients and ensure the reliability of their products in a rapidly changing market.

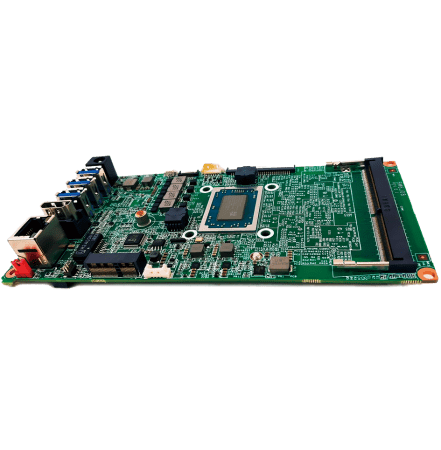

Simplify Your PCB Journey with XPCB Limited

XPCB Limited simplifies the PCB process for you. With our quick-turnaround prototyping and turnkey PCBA services, we ensure that your projects move forward smoothly and efficiently. Trust our commitment to quality and timeliness as we help you bring your designs to life. Choose XPCB Limited for a hassle-free PCB experience.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

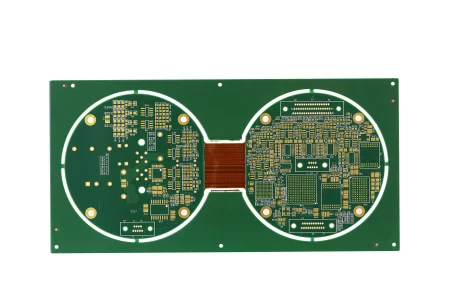

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve