Today’s connector forms and structures are ever-changing, and there are various types of connectors with different application objects, frequencies, power, and application environments.

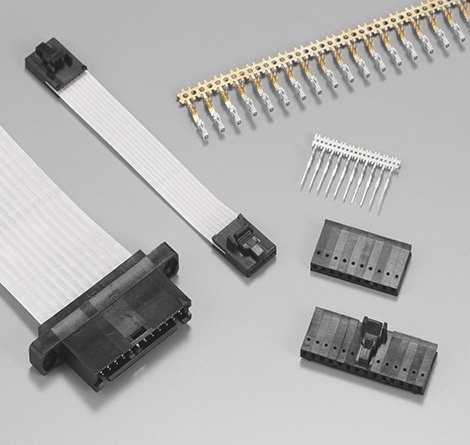

The FFC connector is a

flexible flat cable connector. It is a new type of data cable made of PET insulating material and extremely thin tinned flat copper wire, which is laminated through the production line of high-tech automation equipment. It has soft, flexible bending and folding, Thin thickness, small size, simple connection, convenient disassembly, easy to solve electromagnetic shielding (EMI).

The following mainly talks about the difference between FFC connector and FPC connector, and the commonly used types of FFC connector.

1. Difference between FFC Connector and FPC Connector

The FFC connector is a flexible flat cable connector, and the FPC connector is a flexible printed circuit. From the manufacturing of the two connectors, the way they are formed is different:

a. FFC is a flat copper foil sandwiched between upper and lower insulating foil films. The finished product is simpler and thicker.

b. FPC is to process FCCL (flexible copper clad foil) by chemical etching to obtain flexible circuit boards with different single-sided and double-sided and multilayer structures.

In terms of price, naturally, FFC connectors are much cheaper. If the production cost is taken into account, more companies will like to use FFC connector-related designs.

2. 7 Common Types of FFC Connectors

Type A: Both ends are connected and the reinforcing plate is pasted on the insulating tape;

Type B: Cross the reinforcing plate and paste it directly on the insulating tape;

Type C: The reinforcing plates at both ends are directly pasted on the conductor;

Type D: Cross the reinforcing plates at both ends and paste directly on the conductor;

Type E: one end of the reinforcing plate is attached to the insulating tape, and the other end is directly soldered;

Type F: The reinforcing plates at both ends are directly attached to the insulating tape, and the inner half is peeled off;

Type G: Direct soldering at both ends.

Generally speaking, the development of today’s FFC connector technology has the following characteristics: high-speed and digitization of signal transmission, integration of various signal transmissions, miniaturization and miniaturization of product volume, low-cost products, and contact termination.