- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

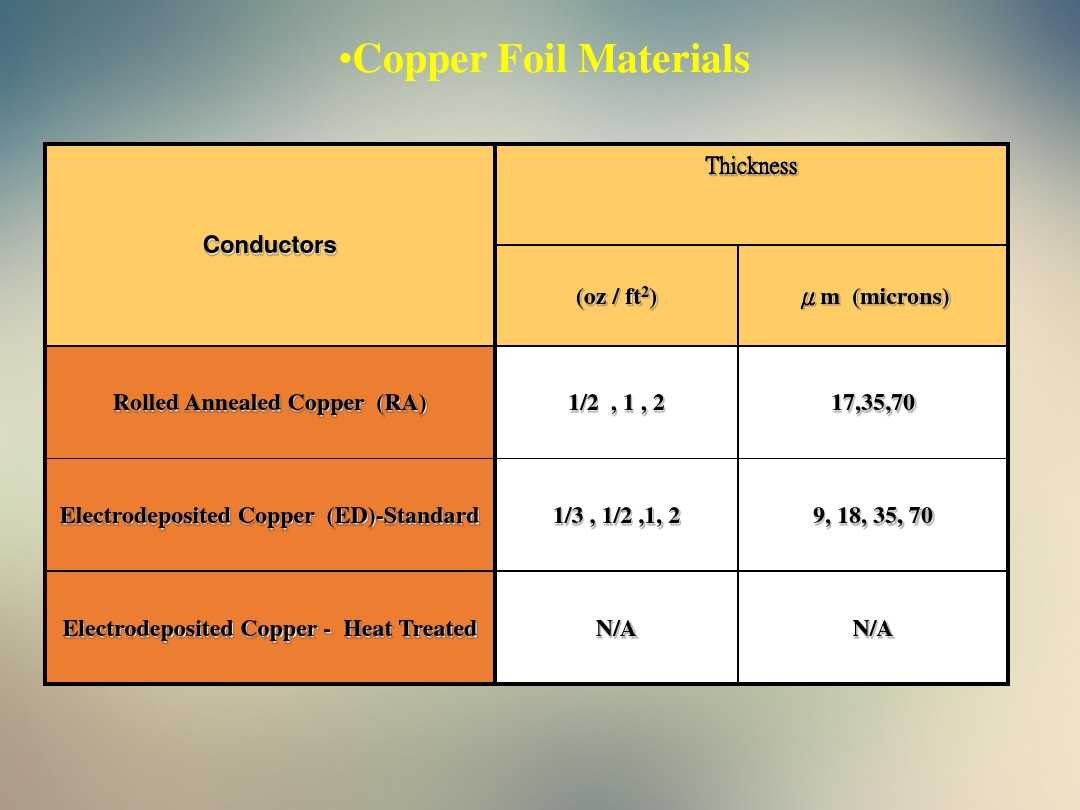

We all know that copper foil is an indispensable material in order to achieve good electrical conductivity of the fpc soft board. The copper foil commonly used to make flexible boards is divided into rolled copper foil and electrolytic copper foil according to different molding methods. So what is the difference between products made of rolled copper foil and electrolytic copper foil?

1. The process of rolled copper foil and electrolytic copper foil are different. Electrolysis is completed by electroplating process, and rolled copper is produced by coating.

2. The properties of rolled copper foil and electrolytic copper foil are different. Electrolytic copper has better conductivity, and rolled copper has better flexibility. Generally, rolled copper is used for products with bending requirements. The unit price of rolled copper is more expensive than electrolytic copper.

The difference between rolled copper foil and electrolytic copper foil

3. Electrolytic copper molecules are relatively loose and easy to break; rolled copper molecules are tight and flexible, and the thinner the better; the phosphorous rolled copper molecules are delicate, and the electroplating surface after treatment is brighter, but the flexibility is worse than pure rolled copper.

4. Electrolytic copper is made by using electric current to precipitate copper ions in the copper sulfate solution, and then it is completed after anti-oxidation and roughening treatments. Calendered copper is made by rolling copper ingots, and then undergoing processes such as forging, anti-oxidation, and roughening treatments.

Compared with electrolytic copper, rolled copper production is more difficult. At present, there are only three companies in the world that can mass produce (according to relevant reports), with good ductility (up to 30% or more, and the best SHTE type of electrolytic copper is only 15 %-20%), mainly used in FPCs, notebook computers, tablet computers, printers and other places that need to be shielded.

Through the comparison of materials, it is not difficult to find that the soft board made of rolled copper foil has better bending performance and softer, which is more conducive to saving the internal space of electronic products. However, the cost of rolling copper foil to make flexible boards is slightly higher.

The cost of the Flexible circuit made of electrolytic copper foil is a bit lower, and the surface is brighter, but it is easy to break during bending, which is suitable for circuit boards that do not require high flexibility.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve