Why Consider Consigned Assembly?

Small businesses often struggle to get their product ideas off the ground due to limited capital. A consigned assembly model can help overcome this challenge. With consigned assembly, also known as vendor-managed inventory or risk-sharing, a contract manufacturer takes ownership of components and assemblies products only when a customer places an order. As a result, businesses avoid upfront costs associated with inventory storage and management. And for assembly houses, consigning inventories opens new revenue streams.

How Does Consigned Assembly Work?

A consigned assembly agreement typically works as follows: Firstly, a small business provides a contract manufacturer with a production design and bill of materials. The assembler then purchases required parts and components using customer-provided purchase orders or lines of credit. During production, the consigned parts remain the property of the assembler until a customer order triggers assembly and transfer of ownership.

In addition, the assembler commits warehouse space to store consigned parts and assemblies until the small business places an order. The parties also agree on terms like pricing models, lead times, minimum order quantities and cancelation fees in advance. Subsequently, whenever the small business needs to fulfill an order, it notifies the assembler who assembles and ships the finished product within the agreed timeline.

Choosing the Right Partner

When opting for consigned assembly, carefully selecting a partner manufacturer is important. Small businesses should look for experience in the target industry domain as this ensures process familiarity. Operational capabilities like vertical integration, logistics expertise and quality certifications also help minimize delays.

Meanwhile, manufacturers like XPCB LIMITED that offer value-added services including package and test, custom system assembly and prototyping give customers a full-stack solution. Transparency regarding production capabilities, facilities and finances also builds long term trust. Agreements with clauses on liability, order changes and dispute resolution further protect both parties’ interests.

Minimizing Costs through Negotiation

Upfront costs are an inevitable concern for cash-strapped startups. However, smart negotiation tactics can lower consignment fees and expenses. Requesting discounted rates for tooling, storage and assembly based on projected volumes shows commitment.

Businesses can also propose consigning generic/common parts that the assembler likely already holds in inventory. Pre-payment for specialty components in bulk often earns discounts as well. Renegotiating terms periodically as volumes grow ensures bespoke solutions tailored to evolving needs. With the right partner, consigned models open up flexible capacity without major investments.

Addressing Potential Drawbacks

While consigning assembly lightens upfront burdens, it is not devoid of risks. Stockouts occur if demand fluctuates wildly versus forecasts. As consigned parts belong to manufacturers, slow-moving items may expire before use. Unused inventory also limits cash flow until offset by future orders.

To mitigate these downsides, frequent reviews of market trends and BOM refinements help match consignments to realistic demand. Close coordination on production planning maintains appropriate balances. Contracts should clearly assign responsibility and replenishment costs for expired parts. With diligent management, businesses can reap consigned assembly’s benefits over its life cycle.

Consigned Assembly Supports Scalability

For startups, there are significant benefits to delaying large capital outlays. Consigning inventory with a manufacturer provides opportunities to scale up manufacturing based on real market sales success without heavy upfront investments. When cash flow allows, ownership of components can transfer gradually to further reduce costs in the long run.

As volumes rise and components stabilize, businesses gain negotiating leverage too. Cost-plus pricing models shift to fixed rates more representative of real spend. Transitioning to vendor-managed inventory also helps maintain lean operations focused on innovation and sales growth. The scalability inherent to consigned assembly matches well with smaller companies’ frequent need to flex production needs.

Collaborate_with_XPCB_Ltd

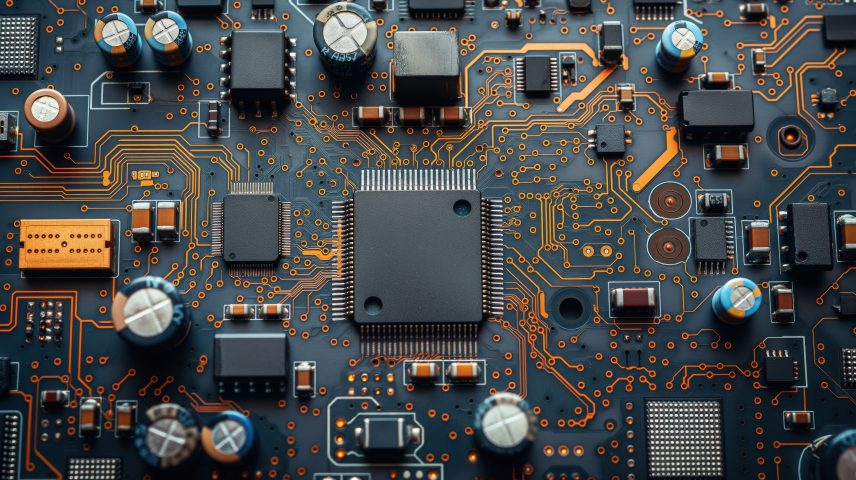

XPCB LIMITEDoffers full-service consignment manufacturing solutions tailored for high-mix low-volume prototype and pre-production demand. By leveraging over a decade’s experience in PCB assembly, the company maintains optimized infrastructure to store a wide range of SMT components on behalf of customers.

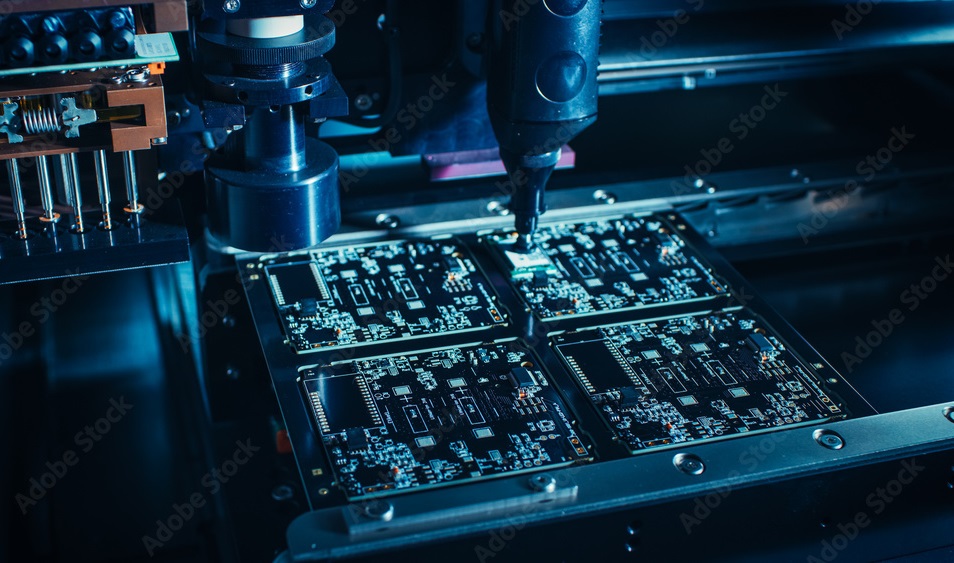

Machines enable just-in-time assembly with low minimum orders. Expert technicians assemble orders to IPC standards from the abundant stock. Advanced systems track inventory usage and costs precisely to maximize efficiency. Businesses benefit from on-demand capacity scaling, accelerated prototyping and reduced total ownership costs in the product development cycle.

Interested parties can visit XPCB LIMITED’s website or contact relevant sales representatives to understand available consignment programs, customized to their specific product roadmaps and budget needs. Long-standing partnerships reflect the manufacturer’s strong commitment to customer success.

The Future of Consigned Manufacturing

The on-going shift to distributed manufacturing models and digital supply chains is expanding consignment’s scope. Future-proof consigned assembly agreements will harness technologies like advanced analytics, IoT sensors and blockchain distributed ledgers.

Real-time Data from production floors improves demand forecasting accuracy and matching inventories to actual needs. Smart contracts self-execute replenishment based on sensor-detected inventory levels. And blockchain secures traceability of inventory ownership transfers, lowers transactional friction and enhances collaboration across distributed partners across borders.

As flexible outsourced manufacturing gains more traction, assembly houses that invest in these emerging tech capabilities will have a competitive edge in serving both established companies expanding internationally and disruptive startups commercializing innovative products sustainably. Consigned manufacturing is sure to play a pivotal role in the industry’s ongoing transformation.

Conclusion

To conclude, consigned assembly provides cash-strapped startups and small businesses an affordable pathway to turn product visions into realities and scale manufacturing based on validated market reception. With the right manufacturer partner supporting requirements, businesses can focus energies on refining offerings, finding customers and driving growth organically. Constant communication ensures shared success across product life cycles. Adopting a consignment model with an experienced partner like XPCB LIMITED opens doors to cost-effectively develop and commercialize innovative technologies.