- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

The demand for compact, high-performance electronic devices has spurred the growth of High-Density Interconnect (HDI) and complex printed circuit boards (PCBs). While these advanced PCBs enable innovative designs and enhanced functionality, their manufacturing often involves higher costs due to intricate processes and specialized materials. In the realm of Printed Circuit Board Assembly (PCBA) services, cost optimization becomes essential to balance performance with affordability.

This blog delves into effective strategies for cost optimization in HDI and complex PCB manufacturing, helping manufacturers streamline production, reduce expenses, and maintain high-quality outputs.

The choice of materials significantly impacts the cost of HDI and complex PCBs. Manufacturers can consider the following approaches:

DFM is a crucial step to ensure that the PCB design aligns with manufacturing capabilities, reducing the likelihood of errors and rework. Key considerations include:

Adopting automation and advanced manufacturing technologies can drive cost efficiency in PCB production:

Building strong relationships with reliable suppliers can yield cost benefits:

Prototyping is essential for validating designs, but it can also be expensive. Strategies to optimize prototyping costs include:

Streamlining production processes helps reduce waste and labor costs. Key measures include:

Efficient assembly techniques can further reduce costs in the PCBA phase:

Sustainable manufacturing practices can lower costs while meeting environmental regulations:

Scaling production effectively can unlock cost savings through economies of scale:

Although it involves upfront costs, investing in research and development can lead to long-term savings:

The manufacturing of HDI and complex PCBs in PCBA services requires a balance between quality, performance, and cost. By adopting the strategies outlined above, manufacturers can optimize costs without compromising on reliability or functionality. From material selection to scalable production processes, each step in the manufacturing journey offers opportunities for cost efficiency. As the demand for advanced electronic devices continues to rise, cost-optimized manufacturing will remain a competitive advantage in the PCB industry.

From Prototyping to Turnkey PCBA – XPCB Delivers Excellence

XPCB Limited is your go-to partner for PCB excellence. We provide a complete range of services, from quick-turn prototyping to turnkey PCBA, to meet the diverse needs of your projects. With an emphasis on innovation, quality, and customer satisfaction, XPCB ensures your PCBs are delivered on time and to specification. Start your journey to success with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

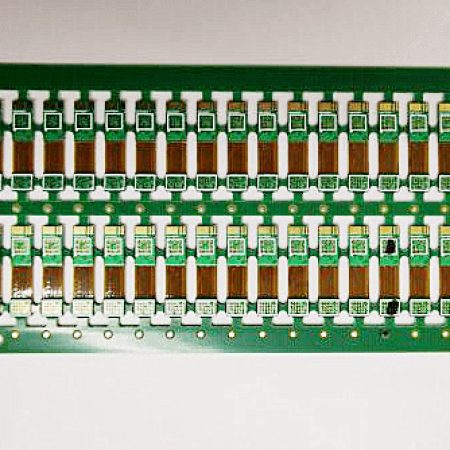

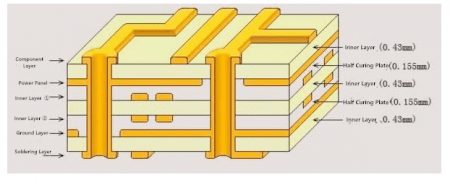

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve