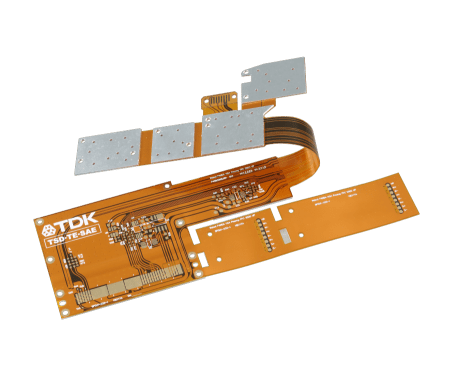

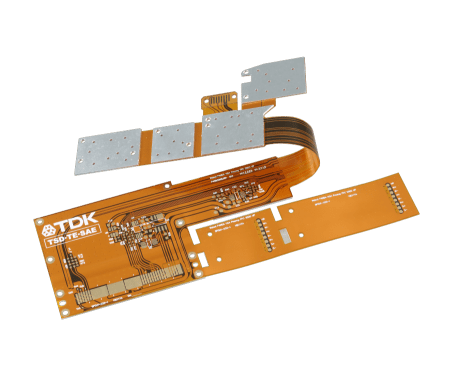

A Rapid Flex PCB is a printed circuit board that is designed for flexibility and high-speed applications. It offers a unique combination of characteristics that make it an ideal choice for a wide range of industries. This documentation provides a brief overview of Rapid Flex PCBs, their benefits, and their applications.

What is a Rapid Flex PCB?

A Rapid Flex PCB is a printed circuit board that is designed to withstand mechanical flexing and twisting. Unlike traditional rigid PCBs, which are susceptible to breakage when subjected to mechanical stress, Rapid Flex PCBs are highly resilient and can withstand significant movement without malfunction.

Benefits of Rapid Flex PCBs

- Flexibility: Rapid Flex PCBs offer exceptional flexibility, allowing them to be bent, folded, or twisted without compromising their performance. This flexibility makes them an ideal choice for applications that require compact and ergonomic designs.

- High-Quality Connections: Rapid Flex PCBs use advanced bonding techniques, such as solderless interconnects or press-fit connectors, to ensure reliable connections between components. These connections are highly resistant to mechanical stress and provide a stable and reliable connection.

- High-Speed Applications: Flex PCBs are highly optimized for high-speed applications, allowing for faster signal transmission and reduced latency. They are commonly used in industries such as telecommunication, aerospace, and medical technology where high-speed performance is of utmost importance.

- Weight and Size Reduction: Compared to traditional rigid PCBs, Rapid Flex PCBs have a lighter weight and smaller footprint. This makes them ideal for applications where size and weight are critical, such as portable devices and wearable devices.

- Abrasion Resistance: Flex PCBs are designed to be resistant to abrasion, making them suitable for applications that require frequent movement or exposure to harsh environments. This durability extends the lifetime of the PCB and reduces the risk of failure.

Applications of Rapid Flex PCBs

- Flexible Electronics: Flex PCBs are commonly used in flexible electronics applications, such as wearable devices, curved screens, and bendable panels. Their flexibility enables them to be integrated into devices with complex shapes or complex folding designs.

- Robotics and Automation: Rapid Flex PCBs find applications in robotics and automation due to their flexibility and resistance to mechanical stress. They are commonly used in robotic joints, grippers, and other moving parts that require high durability and high-speed performance.

- Medical Devices: Flex PCBs are commonly used in medical devices due to their biocompatible properties and resistance to electromagnetic interference. They are commonly used in implantable devices, diagnostic equipment, and surgical instruments.

- Aerospace and Defense: Rapid Flex PCBs find applications in aerospace and defense due to their durability, resistance to vibration, and ability to handle extreme environmental conditions. They are commonly used in aerospace control systems, radar systems, and other critical electronics.

- Automotive: Rapid Flex PCBs are widely used in the automotive industry due to their flexibility, weight-saving properties, and resistance to vibrations. They are commonly found in airbag deployment systems, adaptive suspension systems, and other automotive electronics.

Conclusion

Rapid Flex PCBs offer a unique set of advantages that make them an ideal choice for a wide range of applications. Their combination of flexibility, high-speed capabilities, durability, and resistance to mechanical stress make them a versatile and sought-after solution for industries that require high flexibility and high-performance electronics. As technological advancements continue, Rapid Flex PCBs are expected to play an increasingly significant role in various industries.

Simplify Your PCB Journey with XPCB Limited

XPCB Limited simplifies the PCB process for you. With our quick-turnaround prototyping and turnkey PCBA services, we ensure that your projects move forward smoothly and efficiently. Trust our commitment to quality and timeliness as we help you bring your designs to life. Choose XPCB Limited for a hassle-free PCB experience.