- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In the rapidly evolving automotive industry, where innovation defines success, rigid-flex PCB (Printed Circuit Board) solutions have emerged as a cornerstone of technological advancements. These hybrid PCBs, combining the best attributes of rigid and flexible circuit boards, are driving the future of automotive electronics. This blog explores the transformative role of rigid-flex PCBs in modern vehicles, their benefits, applications, and the road ahead.

Modern vehicles are no longer just mechanical systems; they are complex electronic ecosystems. From advanced driver-assistance systems (ADAS) and infotainment systems to electric vehicle (EV) battery management and autonomous driving technology, the demand for high-performance electronic components has skyrocketed.

At the heart of these systems lie PCBs, the backbone of electronic circuits. Traditional rigid PCBs, while reliable, face limitations in meeting the automotive industry’s growing need for flexibility, compactness, and durability. This is where rigid-flex PCBs step in, offering a robust and versatile solution.

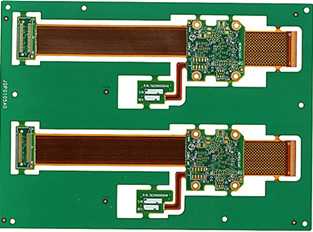

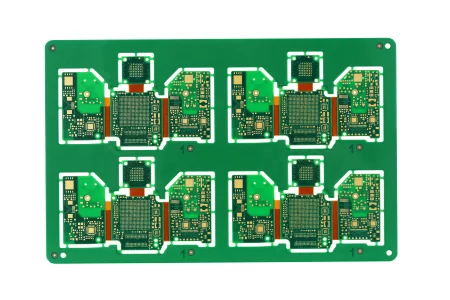

Rigid-flex PCBs combine rigid and flexible layers into a single circuit. The rigid sections provide structural support, while the flexible sections allow for bending, folding, and twisting without compromising electrical connectivity. This hybrid design offers unique advantages, making them ideal for space-constrained and high-reliability applications.

While rigid-flex PCBs offer numerous advantages, they are not without challenges.

The adoption of rigid-flex PCBs in automotive applications is expected to accelerate as the industry moves toward electrification and automation. Emerging trends like connected vehicles, over-the-air (OTA) updates, and smart interiors will further drive demand for advanced PCB solutions.

Additionally, advancements in materials and manufacturing techniques promise to make rigid-flex PCBs more accessible and cost-effective. Innovations like 3D printing and AI-driven design optimization are poised to revolutionize PCB production, paving the way for even more sophisticated automotive technologies.

Rigid-flex PCBs are not just a technological evolution; they are a revolution in automotive electronics. By addressing the industry’s demand for compact, reliable, and high-performance solutions, rigid-flex PCBs are shaping the future of transportation.

As the automotive landscape continues to evolve, embracing these innovative PCBs will be crucial for manufacturers aiming to stay ahead of the curve. With their unparalleled versatility and performance, rigid-flex PCBs are driving automotive technology forward—one circuit at a time.

Your Trusted Partner for PCB Success: XPCB Limited

Let XPCB Limited be your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve