- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

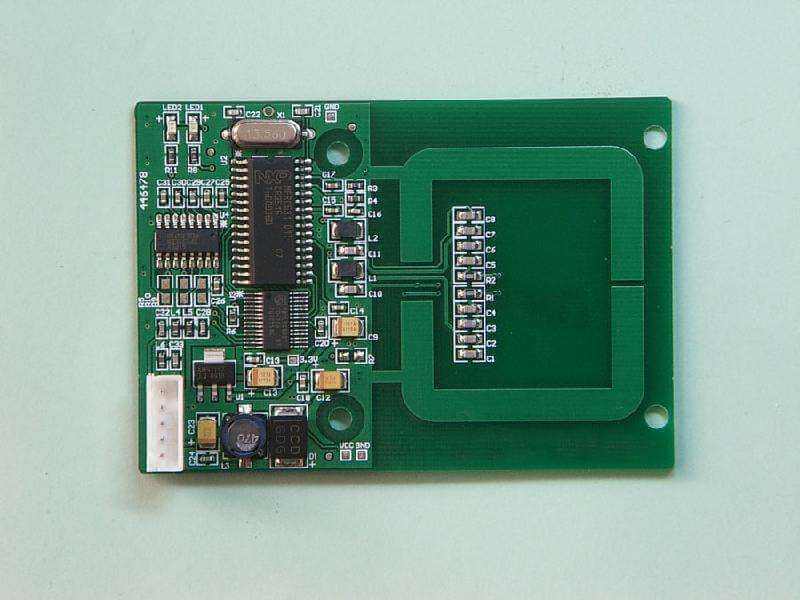

With the development of communication technology, handheld radio frequency circuit technology is more and more widely used, such as: wireless pager, mobile phone, wireless PDA, etc., among which the performance index of radio frequency circuit directly affects the quality of the whole product. One of the biggest characteristics of these handheld products is miniaturization, which means the density of components is very high, which makes the components (including SMD, SMC, bare pieces, etc.) interference is very prominent. If the electromagnetic interference signal is not handled properly, the whole circuit system may not work properly. Therefore, how to prevent and suppress electromagnetic interference and improve electromagnetic compatibility becomes a very important subject in designing RF circuit PCB. The performance index of the same circuit with different PCB design structure can vary greatly.

Selection of Sheet Material

The base material of printed circuit board includes organic type and inorganic type. The most important properties of the substrate are dielectric constant r, dissipation factor (or dielectric loss) tangent, thermal expansion coefficient CET, and moisture absorption rate. The R affects the circuit impedance and signal transmission rate. For high frequency circuits, dielectric constant tolerance is a more critical factor to be considered first, so the substrate with small dielectric constant tolerance should be selected.

PCB design flow

As the Protel99SE software is different from the Protel98 software, the process of PCB design using Protel99SE software is briefly discussed.

After checking without error, archive and output the file. The ‘EXPORT’ command from the ‘FILE’ option must be used in Protel99SE to store files in the specified path and FILE (the ‘IMPORT’ command calls a FILE into Protel99SE). Note: “SAVECOPYAS…” in the ‘FILE’ option in Protel99SE After the command is executed, the filename selected is not visible in Windows98, so it is not visible in explorer. This is the same as “SAVEAS…” in Protel98 Not exactly the same function.

In the basic completion of the components of the layout, you can start wiring. The basic principles of wiring are as follows: after the assembly density permits, low-density wiring design should be selected as far as possible, and the signal routing thickness should be consistent as far as possible, which is conducive to impedance matching.

For RF circuits, unreasonable design of strike, width and spacing of signal lines may cause cross interference between signal transmission lines. In addition, the system power supply itself also has noise interference, so in the design of PCB RF circuit board must be considered comprehensively, reasonable wiring.

When wiring, all wiring should be kept away from the frame of PCB board (2mm or so), so as to avoid potential breakage or breakage during PCB board production. The power line should be as wide as possible in order to reduce the loop resistance. At the same time, the direction of the power line and ground line should be consistent with the direction of data transmission to improve the anti-interference ability. The signal lines should be as short as possible and the number of holes should be reduced as far as possible; The shorter the connection between the components, the better, to reduce the distributed parameters and electromagnetic interference between each other; Incompatible signal lines should be kept away from each other, and parallel lines should be avoided as much as possible, while the signal lines on both positive and negative sides should be perpendicular to each other. When wiring in need of corner address should be appropriate to 135° Angle, avoid turning a right Angle.

The line directly connected with the welding plate should not be too wide, the line should be away from the components not connected as far as possible, in order to avoid short circuit; No hole bottom should be drawn on the components and should be as far as possible away from non-connected components, so as to avoid the occurrence of virtual welding, welding, short circuit and other phenomena in production.

In PCB design of radio frequency circuit, the correct wiring of power line and ground wire is particularly important, and reasonable design is the most important means to overcome electromagnetic interference. A large number of interference sources on PCB circuit board are generated by power supply and ground wire, among which ground wire causes the most noise interference.

The main reason why the ground wire is easy to form emi is the impedance of the ground wire. When there is a current flowing through the ground wire, the voltage will be generated on the ground wire, which will generate the circuit current of the ground wire, forming the circuit interference of the ground wire. When multiple circuits share a ground wire, common impedance coupling occurs, resulting in so-called ground wire noise.

Therefore, the ground wiring of the RF circuit PCB should be as follows:

Layout of components

Because SMT generally adopts infrared furnace hot flow welding to realize the welding of components, the layout of components affects the quality of solder joints and thus the yield of products. For PCB design of RADIO frequency circuit, electromagnetic compatibility requires that each circuit module should not produce electromagnetic radiation as far as possible and have certain anti-electromagnetic interference ability. Therefore, the layout of components also directly affects the interference and anti-interference ability of the circuit itself, which is also directly related to the performance of the designed circuit. Therefore, in the design of RF circuit PCB, in addition to the layout of ordinary PCB design, it is also necessary to consider how to reduce the mutual interference between various parts of the RF circuit, how to reduce the interference of the circuit itself to other circuits and the anti-interference ability of the circuit itself. According to experience, the effect of RF circuit depends not only on the performance index of RF circuit board itself, but also largely on the interaction between it and CPU processing board. Therefore, reasonable layout is particularly important in PCB design.

General principle of layout: components should be arranged in the same direction as far as possible, and the direction of PCB entering the tin-melting system should be selected to reduce or even avoid the phenomenon of bad welding. According to experience, the minimum distance between components should be 0.5mm to meet the requirements of tin melting of components. If the space of PCB board allows, the distance between components should be as wide as possible. For double-sided PCB board, SMD and SMC components should be designed on one side and discrete components on the other side.

Note in the layout:

Conclusion:

The key of RF circuit PCB design is how to reduce the radiation ability and how to improve the anti-interference ability. Reasonable layout and wiring are the guarantee of designing RF circuit PCB. The method described in this paper is helpful to improve the reliability of PCB design of RF circuit, solve the problem of electromagnetic interference, and then achieve the purpose of electromagnetic compatibility.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve