- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Preface

With the rapid development of very large scale integrated circuits (IC), traditional packaging types cannot meet the needs of electronic assembly, and due to the encouragement of higher integrity, smaller circuit board sizes and higher demand, newer packages have appeared. /O count. Among all the new packages mentioned above, BGA (Ball Grid Array) package is the main type with the widest application range, because its diversity overcomes the many limitations of traditional packages. From the point of view of the elements involved in soldering technology, BGA packages are hardly different from traditional packages such as QFP (Quad Flat Package). However, the pins are replaced by solder balls, which can be seen as a revolution in the field of electronic assembly, and has brought about the emergence of derivative packages such as CSP (chip scale packaging). At present, traditional SMT (surface mount technology) must still be used to implement BGA soldering, and BGA soldering assembly equipment can still be performed in ordinary SMT. This article will discuss some of the factors that affect the application of BGA assembly technology, including BGA pad design, solder paste printing, mounting alignment accuracy, soldering temperature profile and soldering defects.

Feasibility of BGA Pad Design

BGA packages are divided into several categories according to different tones. Generally speaking, BGA pad design should first consider the feasibility of CAD tracking and the manufacturability of PCB (printed circuit board). There are also many types of BGA pads, and the following common types can be freely selected within the allowed space.

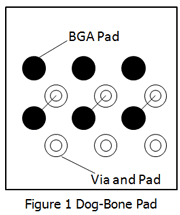

Dog-bone pads use vias to lead traces to other layers, so there are some restrictions on the size of the pads. Due to the existence of vias, some defects are often caused in the PCB manufacturing process, such as solder bridging caused by the peeling off of the solder mask. Therefore, the pad size must be designed strictly in accordance with the actual manufacturing level to minimize the soldering defects generated during the BGA soldering process and leave some space for future BGA rework.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve