- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

With the diversification of uses and compactness, Flexible circuit boards (FPC) used in electronic devices require high-density circuits as well as high performance in a qualitative sense.

Recent changes in FPC circuit density. The subtractive method (etching method) can be used to form a single-sided circuit with a conductor pitch of 30um or less, and a double-sided PCB circuit with a conductor pitch of 50um or less has also been put into practical use. The through-hole diameter between conductor layers connecting double-sided circuits or multilayer circuits is getting smaller and smaller, and now holes with through-hole diameters below 100um have reached the scale of mass production.

Based on the standpoint of manufacturing technology, the possible manufacturing range of high-density circuits. According to the circuit pitch and via hole diameter, high-density circuits are roughly divided into three types: (1) traditional FPC; (2) high-density FPC; (3) ultra-high-density FPC.

In the traditional subtractive method, flex PCB with a pitch of 150um and a via hole diameter of 15um has been mass-produced. Due to the improvement of materials or processing equipment, a circuit pitch of 30um can be processed even in the subtractive method. In addition, due to the introduction of processes such as CO2 laser or chemical etching, mass production and processing of via holes with a diameter of 50um can be achieved, and most of the high-density FPCs currently in mass production are processed by these technologies.

However, if the pitch is less than 25um and the via hole diameter is less than 50um, even if the traditional technology is improved, it is difficult to increase the yield, and new processes or new materials must be introduced. There are various processing methods for the proposed process, but the semi-additive method using electroforming (sputtering) technology is the most suitable method. Not only the basic process is different, but the materials and auxiliary materials used are also different.

On the other hand, the advancement of flexible printed circui board joining technology requires FPC to have higher reliability performance. With the high density of circuits, the performance of FPC has put forward diversified and high-performance requirements. These performance requirements depend to a large extent on the circuit processing technology or the materials used.

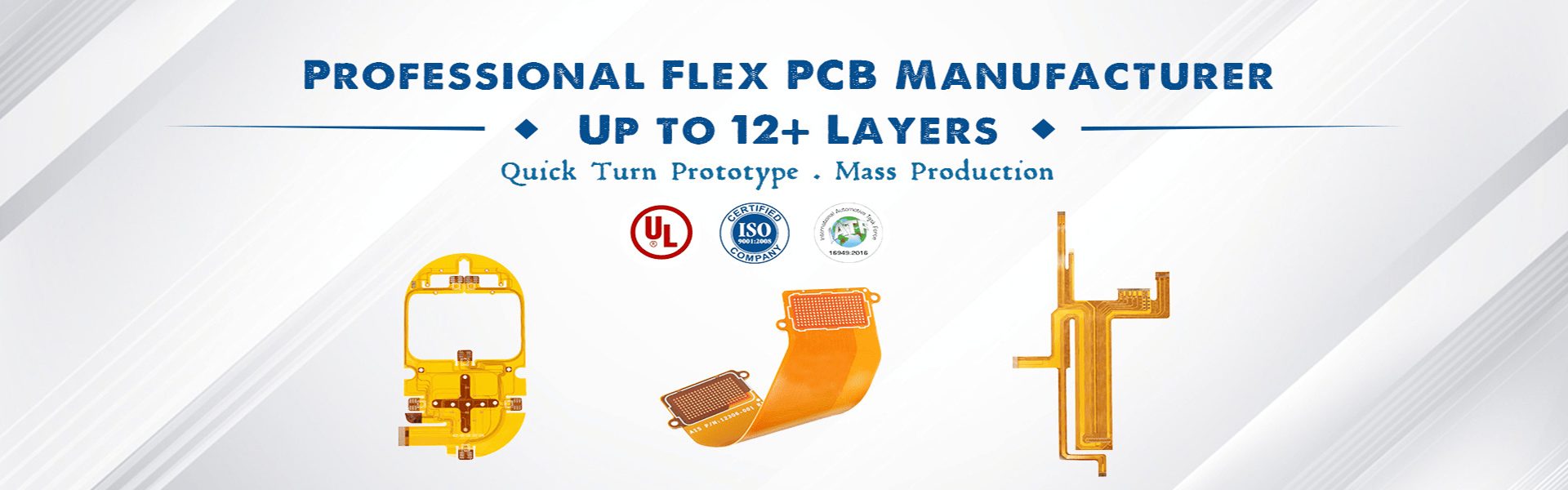

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve