- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

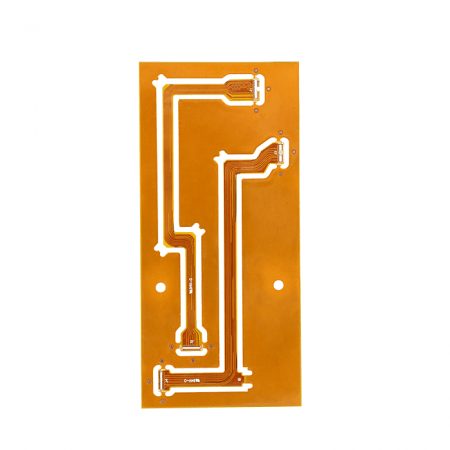

FPC plating is a process in which an electrolyte is applied to a flexible printed circuit board and then plated using an electric current. FPC plating is a technique that applies the electroplating process to flexible circuit boards. The purpose of FPC plating is to increase the size and conductivity of the circuit board so that the board can withstand higher currents and voltages. This plating process typically uses copper as the electrolyte, which forms a thin, uniform layer on the circuit board. This layer can be machined to form the wiring and electrical connections on the circuit board.

FPC plating has many advantages, such as high precision and speed, which can increase the size and complexity of the circuit board to a higher level. In addition, FPC plating can also increase the durability and reliability of the circuit board.

However, FPC plating also has some drawbacks, such as the need for expensive equipment and materials, the need for complex manufacturing processes, and highly skilled workers. In addition, there are some environmental and health concerns associated with flexible PCB plating, such as the generation of hazardous waste and chemicals.

The surface of the copper conductor exposed by the pretreatment flexible printed board FPC after the coating process of FPC plating may be contaminated with adhesive or ink, and there will also be oxidation and discoloration caused by the high-temperature process. To obtain a tight coating with good adhesion, it is necessary to remove the contamination and oxide layer on the conductor surface to make the conductor surface clean.

However, some contaminants are firmly bonded to copper conductors and cannot be completely removed with weak cleaning agents. Therefore, most of them often use alkaline abrasives with a certain strength and brushing for treatment, and most of the covering adhesives are epoxy resins with poor alkali resistance, which will lead to a decrease in bonding strength.

Although it is not obvious, in the FPC plating process, the plating solution may seep through the edge of the overlay, and in severe cases, the overlay may peel off. During the final soldering, solder is drilled under the overlay. It can be said that the pre-treatment cleaning process will have a significant impact on the basic characteristics of flexible PCB FPC, and full attention must be paid to the treatment conditions.

The thickness of FPC plating is directly related to the electric field strength of the electroplating metal, and the electric field strength changes with the shape of the circuit pattern and the position of the electrode.

In the application related to flexible printed boards, there are many wires with great differences in width in the same line, which makes it easier to produce uneven coating thickness, in order to prevent this from happening, a shunt cathode pattern can be attached around the line to absorb the uneven current distributed on the plating pattern, and ensure that the thickness of the plating on all parts is uniform to the greatest extent.

Therefore, it is necessary to work on the structure of the electrode. A compromise scheme is proposed here, the standards for the parts with high requirements for the uniformity of the coating thickness are strict, and the standards for other parts are relatively relaxed, such as the lead-tin plating for melt welding, the gold-plated layer for metal wire lapping (welding) and so on, and for the lead-tin plating for general anti-corrosion, the coating thickness requirements are relatively relaxed.

There is no problem with the smudge and dirt of FPC plating that has just been plated, especially the appearance, but some surfaces appear smudges, dirt, and discoloration soon after, so they should be inspected at the factory

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve