- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In recent years, the rise of smart wearable devices has transformed the way we interact with technology. From fitness trackers to smart glasses, these devices have become an integral part of our daily lives. One of the key components enabling the sleek, compact designs of these devices is Flexible Printed Circuit Boards (FPCBs). This blog explores the significance of FPCBs in smart wearable applications and how they enhance functionality and user experience.

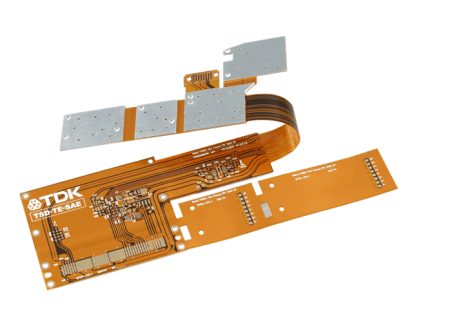

Flexible Printed Circuit Boards (FPCBs) are thin, flexible electronic circuits made from a plastic substrate. Unlike traditional rigid PCBs, FPCBs can bend, twist, and conform to various shapes, making them ideal for applications where space is limited and flexibility is essential. This flexibility allows designers to create innovative products that can adapt to the contours of the human body, enhancing comfort and usability.

One of the most significant advantages of FPCBs is their lightweight nature. In wearable technology, where devices are often worn for extended periods, a lighter design contributes to user comfort. FPCBs enable manufacturers to produce slimmer devices without compromising on functionality. This compactness is particularly important in fitness trackers and smartwatches, where users expect both performance and style.

Wearable devices need to fit snugly against the body to function effectively, especially for applications like health monitoring. FPCBs can be designed to contour to the shape of the wrist, arm, or ear, providing a better fit. This conformability ensures that sensors remain in close contact with the skin, enhancing the accuracy of readings such as heart rate, temperature, and movement.

Smart wearables often incorporate various features, including fitness tracking, heart rate monitoring, GPS, and communication capabilities. FPCBs allow for the integration of multiple components into a single, compact board. This not only saves space but also reduces the complexity of the assembly process. By consolidating components, manufacturers can create devices that offer a wide range of functionalities without becoming bulky.

Wearable devices are subjected to various environmental conditions, including moisture, temperature changes, and physical stress. FPCBs are designed to withstand these conditions, offering greater durability than traditional PCBs. They can resist bending and twisting, which is crucial for devices that may be exposed to vigorous activities. Additionally, FPCBs are less prone to breakage, ensuring a longer lifespan for wearable devices.

Another advantage of FPCBs is their ability to dissipate heat more effectively than rigid PCBs. In smart wearables, where multiple components can generate heat during operation, effective heat management is crucial. FPCBs help maintain optimal operating temperatures, preventing overheating and ensuring that devices function efficiently.

As technology continues to evolve, the role of FPCBs in smart wearables will likely expand. Future innovations may include even thinner and more flexible materials, enabling designers to create devices that are not only functional but also aesthetically pleasing. Advances in printing technology could lead to the development of FPCBs that incorporate additional features, such as integrated sensors or even energy harvesting capabilities.

FPCBs are revolutionizing the design and functionality of smart wearable devices. Their lightweight, flexible nature allows for compact designs that conform to the human body, while also providing the durability and reliability necessary for everyday use. As the demand for innovative wearable technology continues to grow, FPCBs will play a crucial role in shaping the future of this dynamic industry. Embracing this technology will not only enhance user experience but also pave the way for new possibilities in health, fitness, and beyond.

Make Your PCB Dreams a Reality with XPCB Limited

XPCB Limited is your go-to partner for turning your PCB dreams into reality. Our streamlined PCB manufacturing process, combined with quick-turnaround prototyping and turnkey PCBA services, ensures that your projects come to life with ease. Trust in our expertise and dedication to quality as we help you achieve your PCB goals. Join us and experience the difference with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve