- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Introduction to high frequency plate

| Application | Usage frequency |

| Cellular & Pager Telecom | 1 ~ 3ghz |

| Individual receiving base stations or satellites transmit | 13 ~ 24 GHz |

| Automobile collision Prevention system (CA) | 75GHz |

| Direct Broadcast Satellite system (DBS) | 13GHz |

| Satellite frequency reducer (LNB/LNA) | 2 ~ 3GHZ |

| Home reception satellite | 12 ~ 14GHz |

| Global Positioning System (GPS) -40 ~85℃ | 1.57/1.22ghz |

| Automobile and personal receiver satellite | 2.4ghz |

| Wireless portable communication antenna system | 14GHz |

| Satellite small Earth station (VSAT) | 12 ~ 14GHz |

| Digital microwave system (base station to base station reception) | 10 ~ 38GHz |

The basic characteristics of high-frequency substrate materials are as follows:

(1) The dielectric constant (Dk) must be small and stable, usually the smaller the better. The signal transmission rate is inversely proportional to the square root of the dielectric constant of the material, and high dielectric constant tends to cause signal transmission delay.

(2) Medium loss (Df) must be small, which mainly affects the quality of signal transmission. The smaller the medium loss is, the smaller the signal loss will be.

(3) The coefficient of thermal expansion is as consistent as possible with that of copper foil, because inconsistency will cause separation of copper foil in changes of heat and cold.

(4) Low water absorption. High water absorption will affect the dielectric constant and dielectric loss when exposed to moisture.

(5) Other heat resistance, chemical resistance, impact strength, peel strength and other must be good.

Generally speaking, high frequency can be defined as the frequency of more than 1GHz. At present, more used high frequency circuit board substrate is fluoro dielectric substrate, such as PTFE, usually applied in more than 5GHz. In addition, fr-4 or PPO substrate can be used for between 1GHz ~ 10GHz products.

The physical properties of these three high frequency substrates are compared in the following table.

| Fluorine polymer/ceramic | PPO/ epoxy /GF | FR-4 | |

| Dielectric constant (Dk) | 3.0±0.04 | 3.38±0.05 | 4.4 |

| Dielectric loss (Df)10GHz | 0.0013 | 0.0027 | 0.02 |

| Peel strength (N/mm) | 1.04 | 1.05 | 2.09 |

| Heat conductivity (W/m/0K) | 0.50 | 0.64 | — |

| Frequency range | 300MHz ~ 40GHz | 800MHz ~ 12GHz | 300MHz ~ 4GHz |

| Temperature range (℃) | -55 ~ 288 | 0 ~ 100 | 50 ~ 100 |

| Transmission speed (In/ SEC) | 7.95 | 6.96 | 5.82 |

| Water absorption (%) | Low | Medium | High |

At present, epoxy resin, PPO resin and fluorine-based resin are the three types of high-frequency substrate materials. Epoxy resin is the cheapest, while fluorine-based resin is the most expensive.

Considering dielectric constant, dielectric loss, water absorption rate and frequency characteristics, fluorine-based resin is the best, while epoxy resin is poor. When the product application frequency is higher than 10GHz, only fluorine-based resin printed boards can be suitable.

Obvious, fluorine resin high frequency substrate performance is much higher than other substrates, but its shortcoming is in addition to the high cost of poor rigidity, and thermal expansion coefficient is larger. For polytetrafluoroethylene (PTFE), in order to improve the performance with a large amount of inorganic matter (such as silica SiO2) or glass fabric reinforced filler material, to improve the substrate rigidity and reduce its thermal expansion. In addition, because the molecular inert PTFE resin itself, cause it’s not easy to combine with copper foil sex difference, thus more special surface treatment should be combined with copper foil surface. Chemical etching processing method with PTFE surface or plasma etching, increasing surface roughness;

Or in copper foil and polytetrafluoroethylene resin between the increase of a layer of adhesive film layer, improve the binding force, but may have an impact on the performance of the medium.

Fluorine series high frequency board, mainly PTFE series and TEFLON series, PTFE series mainly take ROGERS, NELCO, TACONIC and other brands as the mainstream.

ROGERS material

The Rogers family has R5000, R6000, R3000, TM, R2000, R4000 series. Among them the civil market uses the most is R4000 series.

RO4003 (r =3.38) and RO4350 (r =3.48) materials are also developed for the commercial market. Glass fiber braided fabric is immersed in ceramic thermoplastic resin to form rigid and temperature stable laminate. Its electrical properties are suitable for microwave frequency band.

The mechanical properties of this material are similar to THOSE of FR4. It can be processed with ordinary FR4 production process and used in combination with semi-cured sheet RO4403 to make multilayer boards. RO4350 materials are used in applications requiring UL94V0 grades. Compared to the price of the RO3000 series, the RO4000 offers superior selectivity for low cost microwave circuit applications.

The ROGERS4350 plate thickness is 0.020 “(0.508mm) and the total thickness is 0.023″ (0.584mm) after covering 1OZ copper foil on both sides. There are three sizes: 36″X48″, 36″X24″ and 18″X24”.

In 2019, 5G preliminary commercial, upstream of the core materials such as high frequency copper clad products raw materials with the traditional similar CCL, after downstream PCB manufacturer is suitable for high frequency of high frequency circuit board after applied to the base station antenna module, a power amplifier module components such as equipment, and eventually is widely applied in communication base station (antenna, power amplifier, low noise amplifier, filter, etc.), automotive auxiliary system, space technology, satellite communications, satellite TV, military radar, and other areas of the high frequency communication.

5G high frequency technology puts forward higher requirements for circuits.

The rf circuit with operating frequency above 1GHz is generally referred to as high-frequency circuit. In the process of mobile communication from 2G to 3G and 4G, the communication frequency band develops from 800MHz to 2.5ghz. In 5G era, the communication frequency band will be further improved. PCB board will be equipped with antenna vibrators, filters and other devices in 5G rf.

According to the requirements of the Ministry of Industry and Information Technology, it is expected that the early 5G deployment will adopt the 3.5ghz band, with the 4G band mainly around 2GHz. Generally, the electromagnetic wave with a wavelength of 1~10 mm in the 30~300GHz band is called millimeter wave.

When 5G is commercialized on a large scale, millimeter-wave technology guarantees better performance: extremely wide bandwidth, available spectrum bandwidth of 28GHz frequency band up to 1GHz, available signal bandwidth of 60GHz frequency band up to 2GHz per channel; The corresponding antenna has high resolution, good anti-interference performance and can be miniaturized. The propagation attenuation in the atmosphere is fast, and the close-range secure communication can be realized.

In order to meet the requirements of high frequency and high speed, as well as the problems of poor penetration and fast attenuation of millimeter wave, 5G communication equipment has the following three requirements for PCB performance:

There are two ways to high-frequency PCB, one is the PCB processing process requirements higher, the other is the use of high frequency CCL – to meet the high frequency application environment of the substrate material called high frequency copper clad plate.

There are mainly dielectric constant (Dk) and dielectric loss factor (Df) to measure the performance of high frequency copperplate materials.

The smaller the Dk and Df, the more stable the performance of the high frequency and high-speed substrate is.

In addition, as for rf plates, PCB plates have larger area and more layers, requiring higher heat resistance (Tg, high temperature modulus retention rate) and stricter thickness tolerance of the substrate.

Common circuit board main high frequency and high-speed materials have several kinds: hydrocarbon resin, PTFE, LCP liquid crystal polymer, PPE/PPO, etc.

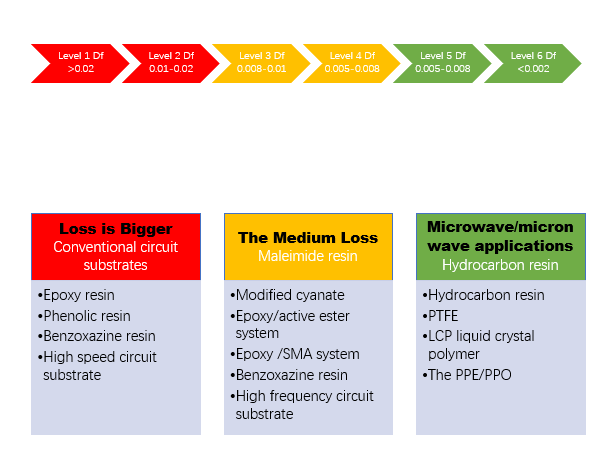

PCB substrate material is divided into 6 levels according to Df size and corresponding resin classification

1. Hydrocarbon resin

Hydrocarbon resin refers to polyolefin homopolymer or copolymer, including butadiene styrene copolymer, butadiene homopolymer, styrene, homopolymer, styrene/divinylbenzene copolymer, styrene – butadiene – divinylbenzene copolymer, etc.

(1) dielectric performance: Dk = / Df = 0.0002 2.4

(2) Higher heat resistance

(3) Good chemical resistance

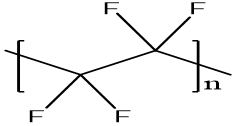

2. PTFE flexible film

PTFE resin melt temperature and melt viscosity are relatively high.

Common commercial forms are resin dispersion, resin suspension and resin powder.

PTFE has high linear expansion coefficient and low thermal conductivity coefficient, so it needs to be modified by reinforcement.

The modified membrane products usually have the following forms:

(3) LCP liquid crystal polymers

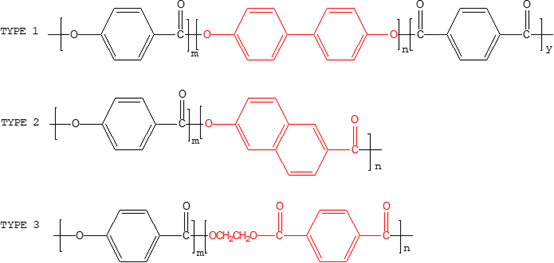

Liquid Crystal Polymer (LCP), it is a new kind of high-performance special engineering plastics developed in the early 1980s.

According to the different formation conditions, liquid crystal can be divided into Thermotropic LCP which is Thermotropic and Lyotropic LCP which is dissolved by solvent.

After hot melt or dissolve, the material will lose the size of the solid macroscopic appearance, hardness, such as rigidity, appearance, won the liquidity of liquid substances, and maintained the orientation order of crystalline substances, thus in the physical form is formed on the opposite sex, and both liquid and liquid crystalline molecules ordered arrangement features of transition state, the intermediate form become liquid crystal state.

From the perspective of molecular design, there are mainly three commercial LCPS:

According to the different molecular structure, the melting point of different types of LCP is not the same, and generally its heat resistance is Type 1 > Type 2 > Type 3.

.

.

| Base Material | RF Parameter | ||

| Dk | Df | Operating frequency | |

| FR-4 | 3.9-4.3 | 0.02-0.025 | <10GHZ |

| PTEE | 2.17-3.20 | 0.0013-0.009 | <20GHZ |

| LTCC (Low Temperature Co-fired Ceramic) | 5.7-9.1 | 0.0012-0.0063 | <12GHZ |

| PI | 4.0 | 0.004-0.007 | <10GHZ |

| LCP | 2.9-3.16 | 0.002-0.0045 | <110GHZ |

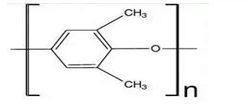

(四)PPE/PPO

Polyphenyl ether is a high-strength engineering plastic developed in the 1960s. Its chemical name is poly2, 6-dimethyl – 1, 4-phenyl ether (PPO) or PPE (Polyphenylene Oxide), also known as Polyphenylene Oxide or Polyphenylene ether.

Two methyl groups closed the phenol ortho position of the active point, making the rigidity, stability, heat resistance and chemical stability. Ether bonds increase flexibility but make them less resistant to heat.

The two methyl groups are hydrophobic non-polar groups, reduce the absorbency and polarity of PPO macromolecules, close the two active phenolic groups, so that the PPO molecular structure of the non-hydrolytic groups, good water resistance, hygroscopicity, dimensional stability and electrical insulation.

A large number of rigid phenolic aromatic rings, the rigidity of the molecular chain and the force between the molecular chains make the internal rotation of the molecular chain segment difficult, resulting in the increase of its melting point, increase of melt viscosity, decrease of fluidity, and difficult processing.

The main suppliers(outside of China) of the above materials are:

| High frequency high speed material | Suppliers |

| Hydrocarbon resin | Crevilli (France), Asahi Kasei (Japan), Tada (Japan), Mitsubishi (Japan), Great Japanese Ink (Japan), etc |

| PTFE | Rogers (USA), Taikangnik (Korea), Yaron (USA), Saint-Gobain (France), Nijas (Japan), etc |

| PPO/PPE | Sabic (USA), Mitsubishi Gas (Japan), Asahi Kasei (Japan), etc |

| LCP | Pauli (Japan), Senanes (USA), Murata (Japan), Cololi (Japan), etc |

The PCB material industry has ushered in a new ERA of 5G. In terms of hardware carriers such as mobile phones, base stations, Internet of Things and automobiles, there will be more demands and higher requirements for 5G new materials.

Learn more about our high frequency board stock and material parameters through our website link.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve